Bernard AccuLock S Consumables | Dual Locked Liner

Bernard® AccuLock™ S liners are locked and concentrically aligned to both the contact tip and the power pin without the use of fasteners to guarantee optimized wire feeding, which eliminates welding liner misalignment and gaps from your troubleshooting list.

Have you ever timed the difference between changing a rear-loading liner and a QUICK LOAD® Liner? We have! As the clock counts away, it took 2:05 minutes to change a QUICK LOAD Liner. As the robot using the QUICK LOAD Liner is already up and welding, the rear-loading liner continues to be installed. There are many benefits to using a QUICK LOAD Liner in addition to reducing downtime. A gun that stays connected to the feeder during liner replacement increases safety, reduces scrap and reduces wear. It also increases safety as there is no need to climb up to boom-mounted feeders or enter robotic cells. It reduces scrap wire as liners are removed and replaced over the wire. Reducing wear on the gun power pin, worn o-rings can cause gas leakage and poor weld quality. It took 3:31 minutes to change the rear loading liner — that’s 40% more production downtime! This was an ideal setup with an easily accessible feeder rear-loading liner replacement downtime increases as access to the feeder becomes more challenging. QUICK LOAD Liner Less Downtime, Less Waste, More Safety. Watch as we compare the time it takes to replace a liner. QUICK LOAD® liners are able to be replaced in half the time of a conventional rear-loading liner.

Changing a conventional liner can cost you in more ways than one. The Tregaskiss® QUICK LOAD® liner AutoLength™ system can help you eliminate those costs.

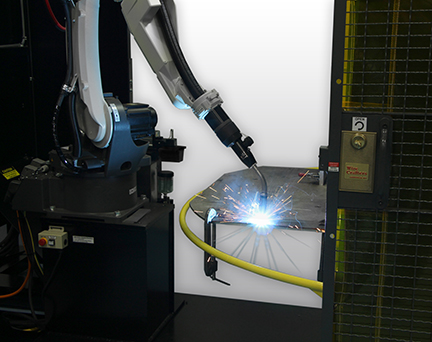

Designed with our unique and durable low-stress robotic (LSR) unicable, TOUGH GUN® TA3 robotic air-cooled MIG guns feed through the arm of today’s through-arm style robots and provide outstanding precision and reliability.

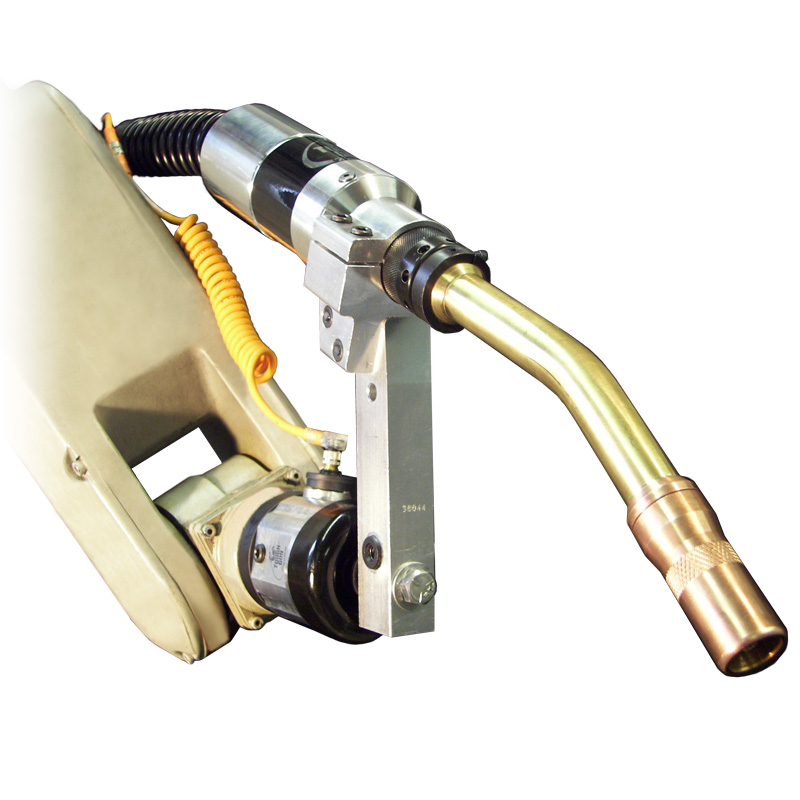

Tregaskiss® fixed automatic MIG guns are engineered for hard tooling automation applications requiring a simple, durable and repeatable MIG gun. Available in air-cooled and water-cooled models, these automatic torches can be configured with the same consumables as your Bernard® semi-automatic or Tregaskiss robotic MIG guns to simplify your inventory.

Tregaskiss® fixed automatic MIG guns are engineered for hard tooling automation applications requiring a simple, durable and repeatable MIG gun. High performance consumables plus the armored neck and body plus the simple internal connections equal a torch that is quick and easy for you to maintain for maximum up-time and throughput. Models available in air-cooled or water-cooled.

Automating spatter removal helps to extend the life of your robotic MIG welding guns and consumables, benefiting your bottom line, production up-time and throughput. Choose between our TOUGH GUN® TT3 reamer (analog model) or our new TOUGH GUN TT3E reamer (Ethernet model), further enhanced with digital Ethernet communication for better integration.

The Tregaskiss® TOUGH GUN® TT3 reamer is TOUGH on spatter and operates reliably in even the harshest welding environments. Automating spatter removal will help to extend the life of your robotic MIG guns and consumables, benefiting both your bottom line and your production up-time and throughput.

Tregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related planned downtime. The longer lifespan of AccuLock contact tips means fewer human interactions within your welding cells and fewer accidental errors as a result. With contact tip cross-threading issues also virtually eliminated, you’ll spend less time troubleshooting and more time on proactive weld quality and productivity initiatives.

Tregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related planned downtime. AccuLock HDP contact tips can increase life by an additional 10x or more in pulse welding applications.

Tregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related planned downtime. AccuLock HDP contact tips can increase life by an additional 10x or more in pulse welding applications. In most cases, your current tip and diffuser can be replaced with no impact to tool center point (TCP), making this upgrade low effort, low risk, and high payoff.

Tregaskiss is making it easier for you to get the exact MIG gun you need — Now you can customize a product for your specific application using our new mobile-friendly online configurators!

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key. Contact tips depend upon repeatability to be effective in the welding process. Learn more about the different types of available — and how choosing the right one for your application can improve results and save money. How do contact tips affect efficiency? When an operation changes contact tips every few hours, there is an obvious effect on productivity. It requires the weld cell to be shut down, and the operator may have to enter the cell to change out the tip. If the robot is buried inside the welding line, contact tip changeover takes even longer. Not only are these changeovers inefficient, but they also introduce the potential for mistakes. Every time a human interacts with the robot, there’s a risk of incorrect consumable installation or other improper adjustments that can lead to poor quality welds and costly rework. Choosing the right tip depends on the results you’re looking for and the needs of the application. In the automotive industry, for example, choosing a quality contact tip is critical since unplanned downtime is the enemy of a high-volume multi-robot operation. Contact tips in these applications need more wear resistance. A high-quality contact tip provides a longer life and a more consistent and stable arc. Longer tip life results in more robot uptime, less time wasted on non-value-added labor for tip changeovers and reduced human interaction with the robot that could lead to error. But the contact tip itself isn’t the only factor impacting tip life — the welding wire, part fit-up, robot programming and grounding also contribute. Different types of contact tipsThere are several types of contact tips available. Understanding the differences can help you select the best choice for your operation. 1. Copper contact tips: Contact tips made from this material are the most conductive to transfer welding current. But copper is also the softest option and will keyhole (or wear the bore unevenly) much faster. If keyholing is a pain point in your operation, this may not be the best choice. The initial cost of copper contact tips tends to be cheaper than other options. 2. Chrome-zirconium contact tips: This alloy provides better wear resistance and longer life than copper tips, holding up better to the demands and increased arc-on time of robotic welding. They are slightly less conductive than copper tips, but they are still sufficient for most robotic applications. 3. HDP contact tips: HDP tips can last 10 times longer than copper tips — and up to 30 times in some cases — depending on the application and waveform being used. Operations may be able to go from changing contact tips every two hours to only changing tips once a week. HDP contact tips are engineered to endure wear better, providing increased resistance to arc erosion in pulsed welding, as well as spray transfer and CV MIG. The precise fit between the tip and the wire also results in good arc stability to help produce high-quality welds. Because HDP contact tips reduce the impact of the welding current decline over time, they can provide a more stable and consistent arc over the life of each contact tip. These tips work best in applications that use high-quality copper-coated solid wire. Common pitfalls with contact tips 1. Only considering price: Many operations may look only at the price per tip when they purchase contact tips. But it’s important to look beyond the initial price and consider the big picture, which includes the downtime and labor required for changeover, along with any quality issues that may be happening in the weld cell. If a contact tip lasts three times as long, the robot can continue to weld instead of being down for a tip changeover — and there is less human interaction inside the cell . 2. Ignoring ID tolerance issues: The size and cast of the welding wire are important in making a decision about contact tips. Some tips need to be undersized for the welding wire used, while some tips need to match the wire size. And the same exact wire will vary in the necessary contact tip size depending on if the wire comes in a small spool or a 1,000-pound barrel. For most copper and chrome-zirconium tips, it’s recommended to undersize the contact tip by a single wire size when using a 500-pound barrel or greater of wire due to the wire cast. With smaller sizes of wire packaging, use contact tips that match the wire size. The goal is to maintain a clean, consistent contact between the wire and the tip so the weld current is conducted as efficiently as possible. 3. Using poor quality wire: In most cases, poor quality welding wire will lead to poor results from your contact tips. This is due to the lubrication on the wire, as well as the consistency of the wire diameter; inconsistent wire diameter wears the tip faster. Choosing a higher quality wire can improve tip life and produce better results. Also, be aware that wires without a copper coating and cored wires wear tips much faster. Using copper-coated solid wires typically slows contact tip wear. 4. Not being open to change: Some companies think the status quo is fine because they aren’t experiencing issues. They change tips in the robotic welding cell every couple of hours, even if those tips don’t need to be changed. Looking at the true length of their current tips or investing in higher-quality tips could optimize efficiency and the overall process — saving unplanned downtime and reducing the need for non-value-added labor hours. Analyzing the robotic operation So how can companies best analyze their robotic welding operation to determine when to change to a different type of contact tip? Contact tips react differently to different applications, so an important first step is to run trials with varying quality levels of tips. This will provide an accurate comparison and a level set for expectations. Run each tip to failure, including the current brand, rather than proactively changing the tip on a set schedule. Be sure to log the time each part lasted. Ideally, run multiple contact tips in any trial to eliminate any outliers. This type of trial can help to identify how much labor time is spent on tip changeovers, how much robot uptime can be achieved and what failures are occurring with each type of contact tip. If an operation previously experienced 10 burnbacks a day and reduces that to zero by using a higher quality contact tip, this can help eliminate unplanned downtime. Optimizing contact tip efficiency in robotic welding Gaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a matter of optimizing the robot and the robotic welding cell to operate at peak efficiency. And while this task is a team effort, it is led by the robotic welding supervisor. So, what can the supervisor do to guide the way, while looking at more advanced considerations? Pay close attention and collaborate. Even if a robotic welding system is meeting production and quality requirements, it’s important that robotic welding supervisors commit to a continuous improvement process. Regularly looking for ways to increase efficiencies could provide the ability to produce more parts. It can also help identify issues within the robotic welding cell before they become problematic and cause downtime. Robotic supervisors should pay close attention to details such as cable and consumable management, parts handling and workflow to pinpoint areas that could be streamlined. The goal is to avoid settling for less than optimal work practices to realize the full potential of the system. Doing so can provide companies with higher productivity and profitability and can set them apart from their competitors. While the robotic welding supervisor may oversee the overall health of a robotic welding cell, the robot operator works hands on with the system daily to load and unload parts. For this reason, they are an excellent resource to rely on for insight into potential or existing problems, such as: • Excessive spatter Quality technicians are another internal resource to help the robotic welding supervisor identify any issues and drive performance improvements. In conjunction with welding engineers, they can help rectify issues like overwelding or part distortion. External sources, such as a robotic welding integrator or equipment manufacturer, can help troubleshoot and offer advice to gain efficiencies. In many cases, they can also offer ongoing training that helps everyone improve their interaction with the robotic welding cell. This article is the second in a two-part series focused on key information welding supervisors should know to help ensure robotic welding success. Read article one, Best Practices for Robotic Welding Supervisors. With careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, such as: • Increased productivity The welding supervisor managing the robotic welding cell plays a key role in achieving these results — and with some best practices in mind, can help ensure long-term success. There are some basics that provide a good starting point. Understand the robotic welding system It’s important for welding supervisors to understand how to quickly troubleshoot issues and how to adjust the weld programs, as needed. Having a solid understanding of the functions of the robotic welding gun, welding consumables, power cables, and their impact on quality and productivity is also important. It makes it easier to identify problems and provide the best solution. Establish documentation and maintenance • The names of all employees who enter the weld cell, when they entered and why This documentation provides insight into changes in the robotic weld cell, making it easier for maintenance staff to troubleshoot any issues. It can also help the welding supervisor and maintenance personnel determine the appropriate frequency for a preventive maintenance schedule, which helps reduce unexpected downtime. When it comes to automating the welding process, many companies opt for robotic welding systems due to the flexibility they provide and their ability to reach and weld multiple joints. These systems provide the advantages of speed and accuracy and can be reprogrammed to manage new projects. But these robotic systems aren’t right for every application. In industries such as oil and gas, railcar, structural steel fabrication and shipbuilding, joint configurations are often less complex, consisting of a single part to be welded as opposed to full assemblies. In this case, fixed automation welding is generally preferred. Fixed automation welding, sometimes called hard automation welding, is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment prior to them being moved to the jobsite where they will be placed into service. It can also be used for welding steel plates for the general fabrication industry or in the manufacturing of hot water heaters and propane tanks. One common factor in these applications is the need for either longitudinal or circular (inside or outside diameter) welds that require repeatability as opposed to versatility. Other factors that make applications suitable for fixed automation welding include: 1. A high volume of similar parts with low variety In some cases, fixed automation welding can help companies meet high production goals at relatively low cost. And it is easy for a single operator to oversee and load parts, making it desirable from a labor perspective — particularly given the shortage of skilled welders the industry is facing. A fixed automation welding cell can be set up in two ways. The first option requires tooling that holds the part in place, while a fixed automatic gun moves along the weld joint by way of a mechanized seam welder or a track and carriage that holds the gun in place. This option would be viable for a long structural beam, for example. In the second scenario, the welding gun may be fixed in a single place by tooling while the part, such as a pipe, rotates on a lathe or circumferential fixture during the welding process. In today’s marketplace, there is equipment that can rotate parts in a wide range of diameters and weights. Tooling for fixed automation welding offers minimal flexibility and can be expensive to adjust for new parts. This is true particularly in comparison to a robotic welding system that can be reprogrammed to articulate and weld in different positions along the X, Y and Z axes. When investing in the tooling for fixed automation welding, it’s important for companies to determine upfront what their long-term applications will be. Will they continue to weld parts that are straight or circular for the foreseeable future? One very important part of the fixed automation welding system is the welding gun. It is not uncommon for companies to take a do-it-yourself (DIY) approach to this piece of equipment, fixturing a semi-automatic gun in place with various components to mimic the performance of a fixed automatic gun. Sometimes this is done out of convenience, due to the shop having an abundance of semi-automatic guns, or because of a perceived cost savings. Unfortunately, a DIY gun assembly for this process can be time-consuming to set up and maintain, which adversely affects productivity. It also is not optimized for fixed automation welding. Quality may suffer due to off-seam welds or other inconsistencies, leading to rework that further reduces throughput and increases costs. Also, if replacement parts are needed there could be variations in the assembly since it is not set up for this process. Again, this can lead to quality issues. Instead, it is important to invest in a fixed automatic gun that is designed for the process. These guns have consistent components that can be sourced from manufacturers so that the welds are repeatable. And the gun manufacturers can provide service and technical support. Guns need to be specified or customized for the application according to the available space, taking into account the distance between the gun and the part and also how far away the wire feeder is. These factors impact neck length and bend or angle, as well as cable choices. Necks are typically available in the marketplace in varying lengths, from approximately 4 to 12 inches, and with either a straight neck or 22-, 45- and 60-degree bends. Companies need to determine the reach required to meet the weld joint, as well as the necessary angle for completing a sound weld. Cable lengths vary from as short as 3 feet to as long as 25 feet. Longer cables are ideal for reaching a wire feeder placed further away from the part, including on a boom. In other situations, a company may mount the feeder directly on the tooling or nearby, in which case a cableless gun is an option for air-cooled operations. These guns plug directly into the wire feeder via a power pin and do not require a cable. Amperage and duty cycle also need to be factored into the selection of a fixed automatic gun, and both depend on the thickness of the material being welded and the amount of arc-on time required. Air-cooled fixed automatic guns are typically available from 300 to 500 amperage models, offering either 60% or 100% duty cycle. Duty cycle is defined by the amount of time within a 10-minute cycle the gun can weld without becoming overly heated. The necks on these guns are particularly durable since they have fewer internal channels than a water-cooled gun and rely on the ambient air to cool them. They are also more resistant to bending, and replacement parts are less expensive. For higher-amperage fixed automation welding applications that require longer periods of welding on thicker material, a water-cooled gun may be a better choice. These models are typically available in amperages ranging from 450 to 600 amps and offering 100% duty cycle. Hybrid water-cooled guns are another option. These fixed automatic guns have a sturdy neck similar to an air-cooled model with water channels running external to it. These channels make the guns easier to maintain than water-cooled guns. Along with selecting the appropriate components for a fixed automatic gun, it’s also essential to choose high-quality consumables — nozzles, contact tips and gas diffusers. This helps minimize downtime for frequent changeovers and supports production goals. They can also reduce quality issues that could require rework later in the welding operation. Consumables are available that can be used across different types of welding guns, including semi-automatic ones and fixed automatic guns. This compatibility can be beneficial to simplifying inventory and preventing errors when installing new consumables on either type of gun. September 23, 2020 We are proud to announce new AccuLock R consumables are now available for Tregaskiss 600 amp robotic water-cooled MIG guns. Convert your existing gun from TOUGH LOCK® to AccuLock R consumables with no impact to Tool Center Point (TCP), or configure your new Tregaskiss 600 amp robotic water-cooled MIG gun with AccuLock R consumables today! The 600 amp robotic water-cooled MIG gun is ready to take on your most demanding welding applications. Its rugged design is tough and dependable enough to maximize productivity when welding thick plate or running prolonged duty cycles. AccuLock R consumables are designed for increased tip life, and virtually eliminate contact tip cross-threading issues to help reduce both your planned and unplanned downtime. September 23, 2020 Tregaskiss is pleased to announce updates to our fixed automatic series MIG guns: AccuLock™ R consumables are designed for increased tip life, and virtually eliminate contact tip cross-threading issues to help reduce both your planned and unplanned downtime. Customers can configure all fixed automatic MIG guns to required specifications or reverse lookup existing gun part numbers. Tregaskiss® MW1 fixed automatic water-cooled MIG gun part numbers have been changed from the 46 and 64 series part numbering convention. Customers can look up legacy part numbers using the new Tregaskiss MW1 MIG gun part number conversion tool. Get more information for all consumables and replacement parts for your Tregaskiss fixed automatic MIG guns: Learn more about our fixed automatic MIG guns or AccuLock R consumables. August 18, 2020 Customers may notice that some Tregaskiss® and Bernard® MIG welding product owner’s manuals look different than previous versions. This is because we recently refreshed the design and format of these product manuals, but their contents remain the same. No changes to the important installation, maintenance, troubleshooting, parts lists and other information and instructions have been made. Printed inventory will be replaced as a running change. August 12, 2020 Tregaskiss will discontinue the sales of ACA and ACB series automatic air-cooled MIG guns (formerly branded Bernard®) and parts as of January 31, 2021. Click here for a list of affected part numbers Tregaskiss® Auto Head Fixed Automatic Air-Cooled MIG Guns are available as replacements. Please reach out to your ITW Welding sales representative for assistance. If you have any questions regarding these changes, please kindly contact your local representative. Learn more about our Tregaskiss Fixed Automatic MIG Guns August 11, 2020 We are pleased to announce that the AccuLock S consumables system has been expanded to include new Lincoln®, Tweco® #4 and Tweco® #5 AccuLock S power pins. These three new power pins are also configurable options in our online BTB MIG gun configurator. The AccuLock S consumables system is designed to address liner trim length errors and erratic wire feeding. The AccuLock S liner is locked and concentrically aligned to both the contact tip and the power pin without the use of fasteners, which provides a flawless wire-feed path that guarantees smooth, uninterrupted delivery of the wire to the weld puddle. Plus, the liner replacement process has been error-proofed so you can trim your liner accurately and easily every time, with no measuring. Important Note: Reduce troubleshooting, production downtime and rework with AccuLock S Consumables. BEECHER, Ill./WINDSOR, Ontario. (August 4, 2020) — Bernard and Tregaskiss have announced the availability of a joint MIG Welding Guns & Consumables catalog. The 46-page, full-color catalog includes a consumable comparison chart to compare contact tip, nozzle and diffuser types across the brands’ available consumables offerings, along with a consumables and MIG gun series compatibility chart to guide users in their selection. The catalog offers easy-to-read key features and part numbers for its products and is organized by product category, first highlighting the brands’ exclusive AccuLock™ S and AccuLock R Consumables — both designed to reduce downtime and improve welding performance. Also included in the catalog are product details and configurator overviews for customizing Bernard® Semi-Automatic MIG Guns, Tregaskiss® Robotic MIG Guns, Clean Air™ Guns and more. Tregaskiss Fixed Automatic MIG Guns for hard tooling applications are also featured. Each page includes website QuickLinks with URLs users can visit to learn more about a specific product, plus service and support contact numbers and directions to explore online resources, such as videos and product configurators. The catalog can be downloaded as a PDF or ordered as a printed copy at Tregaskiss.com/literature. August 4, 2020 Effective immediately, you may notice a slight change to the crimp area of some Tregaskiss® nozzles. Within our manufacturing process, we have begun to transition from six-jaw to eight-jaw crimpers. Rest assured that the durability and performance of Tregaskiss nozzles will remain the same. The only difference you will notice is a slight change limited to the crimp area of the nozzle. Timeline for Transitioning to Eight-Jaw Crimpers For complete product information: December 1, 2017 As of December 29, 2017, all TOUGH GUN® G2 and ThruArm® G2 series robotic air-cooled MIG guns will be discontinued as they are being replaced by TOUGH GUN CA3 and TOUGH GUN TA3 robotic air-cooled MIG guns. The TOUGH GUN G2 and ThruArm G2 series product lines will be fully supported with replacement parts (necks, cables, gun modules) until the end of 2018.

Video | Tregaskiss QUICK LOAD Liner Replacement Race

Tregaskiss QUICK LOAD Liner Replacement Race

Animation | Tregaskiss QUICK LOAD Liner AutoLength System

Tregaskiss QUICK LOAD Liner AutoLength System Animation

Animation | TOUGH GUN TA3 Robotic Air-Cooled MIG Welding Guns

TOUGH GUN TA3 Robotic Air-Cooled MIG Welding Guns Animation

Animation | Tregaskiss Fixed Automatic MIG Guns

Tregaskiss Fixed Automatic MIG Guns Animation

Video | Tregaskiss Fixed Automatic MIG Guns

Tregaskiss Fixed Automatic MIG Guns

Animation | Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations Animation

Video | Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

Video | Tregaskiss AccuLock R Consumables for Better Throughput

Tregaskiss AccuLock R Consumables for Better Throughput

Video | Tregaskiss AccuLock HDP Contact Tips

Tregaskiss AccuLock HDP Contact Tips

Animation | Tregaskiss AccuLock R Consumables

Tregaskiss AccuLock R Consumables Animation

Video | Configure your Tregaskiss Robotic MIG Gun and Reamer Online

Configure your Tregaskiss Robotic MIG Gun and Reamer Online

Selecting Contact Tips for Robotic Welding

Selecting Contact Tips for Robotic Welding

The job of the contact tip is to transfer the welding current to the arc and guide the welding wire as consistently as possible. If either of these two factors degrade, the overall welding process also degrades, affecting quality.

fuse in the fuse box that is your robotic

welding cell. But this small fuse can have

a big impact on productivity.

Once you understand the types of contact tips available, there are numerous factors to consider when choosing the right tip for your application. Here are some common mistakes operations make when choosing contact tips so you can avoid the same pitfalls:

If contact tips are being removed proactively even when there is no keyholing, burnbacks or erratic arcs, there could be potential to get more life out of contact tips.

It’s important to look beyond the purchase cost and consider the big picture to best evaluate the potential productivity, as well as weld quality and efficiency gains of certain contact tips. The benefits can be especially significant in robotic welding applications, where regular contact tip changeovers can be greatly reduced.How Robotic Welding Supervisors Can Improve the Operation

How Robotic Welding Supervisors Can Improve the Operation

Find opportunities for improvement

Rely on available resources

• Poor joint configurations, or

• The need for tooling adjustmentsBest Practices for Robotic Welding Supervisors

Best Practices for Robotic Welding Supervisors

• High weld quality

• Cost saving

• Parts consistency

To maximize uptime in a robotic welding system, welding supervisors need to look beyond the administrative and operational duties often involved with this position and consider the actual components in the system. Maintenance personnel can often help.

Keeping an accurate, detailed log of all activities in a robotic welding cell can help welding supervisors maintain control over changes that could impact performance of the robotic welding system. Information to document includes:

• Parts that have been cleaned

• Consumable changes

• Drive roll tension adjustments

• Installation of a new welding wire drumThis article is the first in a two-part series focused on key information welding supervisors should know to help ensure robotic welding success. Read article two, How Robotic Welding Supervisors Can Improve the Operation.

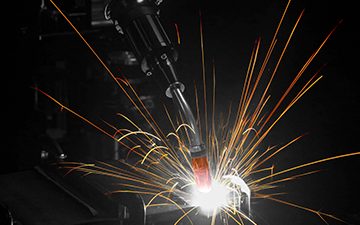

Understanding Fixed Automatic Welding Guns

Understanding Fixed Automatic Welding Guns

About fixed automation welding

2. Large parts with very long welds or several similar welds

3. Large parts that would be difficult to weld manuallyAvoiding pitfalls in the process

Looking at the choices

Additional considerations

PRODUCT UPDATE — Tregaskiss® 600 amp Robotic Water-Cooled MIG Guns Now Available With AccuLock™ R Consumables

PRODUCT UPDATE — Tregaskiss® 600 amp Robotic Water-Cooled MIG Guns Now Available With AccuLock™ R Consumables

Spec Sheet: English

PRODUCT UPDATE — Tregaskiss Fixed Automatic Series MIG Guns

PRODUCT UPDATE — Tregaskiss Fixed Automatic Series MIG Guns

Now available with AccuLock R consumables

New Online Configurators and Reverse Lookup Tools

Part number change to MW1 fixed automatic water-cooled MIG guns

New Spec Sheets

PACKAGING CHANGE — Formatting Changes to Owner’s Manuals

PACKAGING CHANGES —

Formatting Changes to Owner’s Manuals

Tregaskiss® Product Owner’s Manuals Tregaskiss® Product Owner’s Manuals Bernard® Product Owner’s Manuals Bernard® Product Owner’s Manuals

Old Format New Format Old Format New Format

The most current version of these newly formatted owner’s manuals, along with other product manuals and spec sheets, are available for download from our website from the respective product pages as well as the Spec Sheets and Owner’s Manuals page.DISCONTINUED PRODUCTS — ACA and ACB Series Automatic Air-Cooled MIG Guns

DISCONTINUED PRODUCTS –

ACA and ACB Series Automatic Air-Cooled MIG Guns

Replacement Gun Option

NEW PRODUCT – Expanded AccuLock™ S Power Pin Offering

NEW PRODUCT – Expanded AccuLock™ S Power Pin Offering

Lincoln® Tweco® #4 Tweco® #5

Part Numbers

Feeder Manufacturer AccuLock S Power Pin AccuLock S Power Pin Cap AccuLock S Power Pin Cap AccuLock S Power Pin Cap 0.023″-0.030″ 0.030″-0.045″ 0.045″-3/32″ Lincoln® 2200210 2200192 2200193 2200212 Tweco® #4 2200150 2200183 2200184 2200209 Tweco® #5 2200157 2200186 2200187 2200208

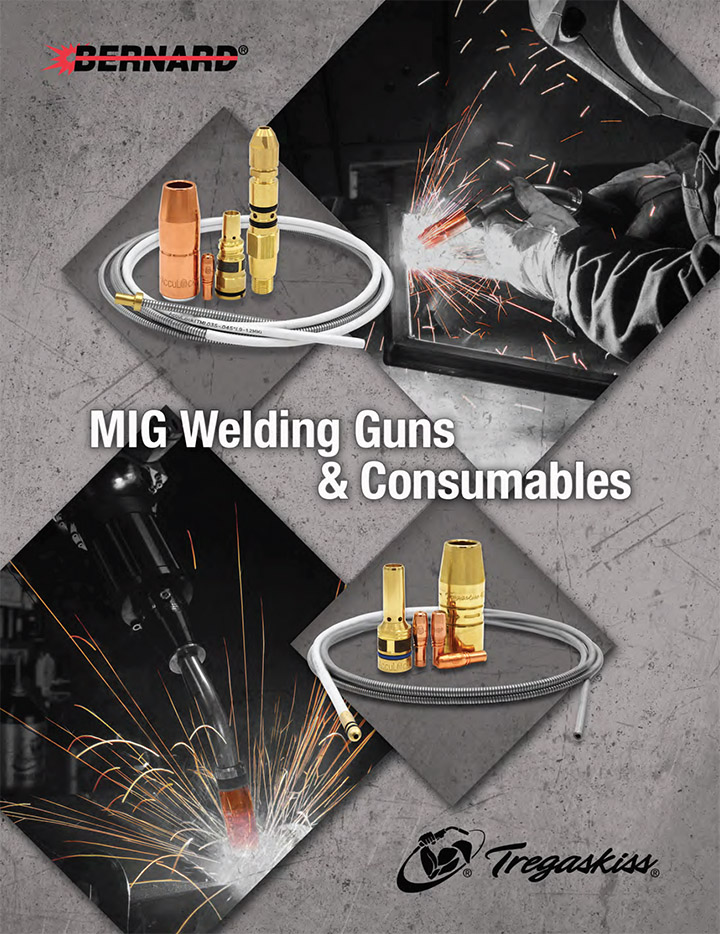

The AccuLock S consumables system requires all AccuLock components: contact tip, diffuser, nozzle, liner, neck insulator, power pin and power pin cap.Bernard and Tregaskiss Release New MIG Welding Guns & Consumables Catalog

Bernard and Tregaskiss Release New MIG Welding Guns & Consumables Catalog

PRODUCT CHANGE — Changes to Crimping on Select Nozzles

PRODUCT CHANGE — Changes to Crimping on Select Nozzles

The difference is shown below:

Part Number: 401-6-62 Assembled with a six-jaw crimper Part Number: 401-6-62 Assembled with an eight-jaw crimper Part Number 401-20-62 Assembled with a six-jaw crimper Part Number 401-20-62 Assembled with an eight-jaw crimper

(Actual ship dates will be dependent upon existing inventory levels at time of assembly transition)

AccuLock™ R Consumables

TOUGH LOCK® Consumables DISCONTINUED PRODUCT – TOUGH GUN G2 and ThruArm G2 Series MIG Guns

DISCONTINUED PRODUCT –

TOUGH GUN G2 and ThruArm G2 Series Robotic Air-Cooled MIG Guns

Affected Part Numbers:

Download PDF Archived Tech Guides:

Download PDF Archived Technical Inserts: