Learn more about welding automation, robotic MIG guns, welding consumables and more from our informative technical articles and case studies. To have new articles delivered to your inbox, please sign up for our Amperage e-newsletter.

- Tips for Improving MIG Welding

Maintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take to achieve those goals vary. Still, there is one constant: the value of skilled welders. They are at the heart of the operation and help ensure its success. Having the right equipment and understanding how to […]

Maintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take to achieve those goals vary. Still, there is one constant: the value of skilled welders. They are at the heart of the operation and help ensure its success. Having the right equipment and understanding how to […] - Selecting Contact Tips for Robotic Welding

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key. Contact tips depend upon repeatability to be effective in the welding process. Learn more about […]

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key. Contact tips depend upon repeatability to be effective in the welding process. Learn more about […] - How Robotic Welding Supervisors Can Improve the Operation

Gaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a matter of optimizing the robot and the robotic welding cell to operate at peak efficiency. And while this task is a team effort, it is led by the robotic welding supervisor. Even if a robotic welding system is meeting […]

Gaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a matter of optimizing the robot and the robotic welding cell to operate at peak efficiency. And while this task is a team effort, it is led by the robotic welding supervisor. Even if a robotic welding system is meeting […] - Best Practices for Robotic Welding Supervisors

With careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, such as: It is important for welding supervisors to understand how to quickly troubleshoot issues and how to adjust the weld programs, as needed. • Increased productivity• High weld quality• Cost saving• Parts consistency The welding supervisor […]

With careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, such as: It is important for welding supervisors to understand how to quickly troubleshoot issues and how to adjust the weld programs, as needed. • Increased productivity• High weld quality• Cost saving• Parts consistency The welding supervisor […] - Understanding Fixed Automatic Welding Guns

Fixed automation welding is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment prior to them being moved to the jobsite where they will be placed into service. When it comes to automating the welding process, many companies opt for robotic welding systems due to the flexibility they provide and […]

Fixed automation welding is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment prior to them being moved to the jobsite where they will be placed into service. When it comes to automating the welding process, many companies opt for robotic welding systems due to the flexibility they provide and […] - How to Prevent Common Causes of Poor Welding Wire Feeding

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost. Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird-nesting and more. To simplify troubleshooting, it’s best to look for issues in […]

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost. Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird-nesting and more. To simplify troubleshooting, it’s best to look for issues in […] - AccuLock R Consumables Reduce Downtime in Robotic Welding

In many cases, equipment-based solutions can be a means to gain success in the robotic welding operation. They can mitigate costly risks and eliminate issues that lead to inefficiencies. And often, these issues are related to a small but significant part of the robotic welding process — the welding consumables. The right welding consumables can […]

In many cases, equipment-based solutions can be a means to gain success in the robotic welding operation. They can mitigate costly risks and eliminate issues that lead to inefficiencies. And often, these issues are related to a small but significant part of the robotic welding process — the welding consumables. The right welding consumables can […] - How to Successfully Implement a Robotic Welding System

In today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: to address a shortage of skilled labour, to improve quality, to decrease waste and rework, and/or to increase productivity — in short, to seek benefits that provide a competitive edge. Not all companies, however, are successful […]

In today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: to address a shortage of skilled labour, to improve quality, to decrease waste and rework, and/or to increase productivity — in short, to seek benefits that provide a competitive edge. Not all companies, however, are successful […] - Improving Welding Automation Safety With Risk Assessment and Training

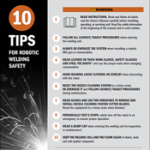

Download10 Tips for Robotic Welding Safety Robotic welding systems continue to gain in popularity due to their ability to increase productivity, improve quality and decrease costs in the right application. But they also offer a way to address a shortage of skilled labor for manual operations. Welding automation provide companies with a means of staying […]

Download10 Tips for Robotic Welding Safety Robotic welding systems continue to gain in popularity due to their ability to increase productivity, improve quality and decrease costs in the right application. But they also offer a way to address a shortage of skilled labor for manual operations. Welding automation provide companies with a means of staying […] - Selecting the Right MIG Welding Consumables

MIG welding gun configurators, like the Bernard® BTB semi-automatic air-cooled MIG gun configurator, allow you to choose specific styles or types of consumables to match the demands (amperages and waveforms) of your application. Selecting contact tips Know the wire size and type when choosing the size and style of contact tip. Contact tips with coarse […]

MIG welding gun configurators, like the Bernard® BTB semi-automatic air-cooled MIG gun configurator, allow you to choose specific styles or types of consumables to match the demands (amperages and waveforms) of your application. Selecting contact tips Know the wire size and type when choosing the size and style of contact tip. Contact tips with coarse […]

Articles by Category

- Customer Testimony | Tico Adopts Bernard MIG Welding Guns & ConsumablesUsing Bernard® Q-Gun™ semi-automatic air-cooled MIG guns and Centerfire™ consumables, Tico Terminal Trucks and Trailers improved productivity […]

- Customer Testimony | Graham Corporation Adopts Bernard MIG Guns and ConsumablesLearn what Graham Corporation has to say about Bernard® MIG guns and consumables.

- Customer Testimony | Bernard MIG Welding Consumables Save Time and Last LongerBernard® MIG welding consumables help Taylor Machine Works save time by reducing contact tip changeover in its […]

- Customer Testimony | Bernard Replaceable MIG Gun Parts Save Money, Improve PerformanceTaylor Machine Works saves money by welding its forklifts with Bernard® MIG guns — all parts are […]

- Customer Testimony | Welding students in Tulsa benefit from Bernard MIG guns and consumablesTulsa Welding School’s Houston campus needs reliable equipment that can handle any process. Bernard® MIG guns and […]

- Customer Testimony | Blinn Instructors Choose Bernard MIG Guns and Consumables for Dependable Welding EquipmentBlinn College welding school instructors and students agree – Bernard® MIG guns and consumables are the welder’s […]

- Video | Bernard Centerfire Changing Consumables ChallengeWatch as we compare the time it take to change Bernard® Centerfire™ consumables on our BTB MIG […]

- Video | Bernard AccuLock S Consumables for the Inexperienced WeldersAs you support more inexperienced welders, choosing equipment with fewer points of failure and simplified maintenance can […]

- Video | Bernard AccuLock S Consumables for Better ProductivityMeet Sam, a semi-automatic MIG Welding Supervisor at an Industrial Company. Sam’s faced with increasing manufacturing growth […]

- Animation | Bernard AccuLock S Consumables No Measuring RequiredChallenged by increasing welder retirements and turnover while orders keep growing year over year? As you support […]

- Animation | Bernard AccuLock S Consumables Dual Locked LinerBernard® AccuLock™ S liners are locked and concentrically aligned to both the contact tip and the power […]

- Video | Tregaskiss QUICK LOAD Liner Replacement RaceTregaskiss QUICK LOAD Liner Replacement Race Have you ever timed the difference between changing a rear-loading liner […]

- Animation | Tregaskiss QUICK LOAD Liner AutoLength SystemChanging a conventional liner can cost you in more ways than one. The Tregaskiss® QUICK LOAD® liner […]

- Video | Tregaskiss AccuLock R Consumables for Better ThroughputTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and […]

- Video | Tregaskiss AccuLock HDP Contact TipsTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and […]

- Animation | Tregaskiss AccuLock R ConsumablesTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and […]

- Selecting Contact Tips for Robotic WeldingContact tips are often referred to as the smallest fuse in the fuse box that is your […]

- AccuLock R Consumables Reduce Downtime in Robotic WeldingIn many cases, equipment-based solutions can be a means to gain success in the robotic welding operation. […]

- Selecting the Right MIG Welding ConsumablesMIG welding gun configurators, like the Bernard® BTB semi-automatic air-cooled MIG gun configurator, allow you to choose […]

- Common Problems With MIG Welding Consumables and How to Fix ThemDownload: Helpful Hints to Avoid MIG Gun Consumable Problems MIG welding consumables are a critical but often […]

- MIG Welding Consumables Reduce Wire Feeding Issues and DowntimeWhen MIG welding consumables aren’t properly installed or maintained, it can result in wire- feeding issues and […]

- New HDP Contact Tips Provide Robotic Pulsed MIG Welding BenefitsOptimizing the robotic weld cell helps improve productivity, allowing a manufacturing facility to save time and money. […]

- What MIG Gun Neck is Right for You?Black polymer armored MIG gun necks contain a thick copper wall with a conductor tube interior, so […]

- Steps for Proper MIG Gun Liner InstallationA MIG gun liner is an important consumable because it can make a significant difference in gun […]

- Considerations for Consumables in Robotic Welding ApplicationsInvesting in a robotic welding system goes beyond the initial purchase — it is equally important to […]

- Ways to Get the Most Out of Your MIG Gun ConsumablesAlthough MIG gun consumables may seem like small part in the welding process, they can have a […]

- Correct Contact Tip Recess Can Improve Welding EfficiencyIn many cases, MIG gun consumables may be an afterthought in the welding process, as concerns with […]

- Selecting the Right Size Contact TipWhile only one part of a much larger system, the contact tip in both robotic and semi-automatic […]

- Tips for Choosing the Right Contact TipSelecting equipment to provide the highest quality and productivity in a welding operation goes beyond just the […]

- Understanding and Extending Contact Tip LifeContact tip failure not only hinders productivity by creating downtime for change over, but it can also […]

- How to Choose the Right MIG Gun LinerMIG gun consumables, including the liner, can make significant difference in gun performance and weld quality. A […]

- Tips for Proper Liner Installation to Help Optimize MIG Gun PerformanceMIG gun consumables are often one of the most overlooked portions of the welding operation. However, choosing […]

- Consumables for High Amperage Welding: What to Know to Minimize Downtime, Costs and Quality RisksWelding is a tough business requiring equally tough equipment. When it comes to high amperage applications that […]

- Selecting Consumables for Robotic Welding and Making Them LastCompanies make the investment in welding automation with an eye toward the potential long-term benefits it can […]

- Quality of Consumables Can Play a Role in Welding Productivity, CostsConsumables — contact tips, nozzles and gas diffusers (or retaining heads) — play an important role in […]

- Bernard Consumables and MIG Guns Help OEM Fabricators Standardize Their OperationsBernard Consumables and MIG Guns Help OEM Fabricators Standardize Their Operations Bernard Q-Guns and Centerfire Consumables have […]

- Understanding MIG Gun LinersThe liner is often overlooked as the cause of MIG welding problems, partially because it is difficult […]

- Making Your MIG Gun Consumables LastSimple Ways to Save Money, Improve Weld Quality and Minimize Downtime Even though many consider MIG gun […]

- Understanding MIG Welding NozzlesNozzles that feature a fiberglass insulator and brassinsert, as shown in this cut-away, can help extendthe life […]

- Handling, Installing, and Maintaining GMAW ConsumablesTips to Follow and Pitfalls to Avoid Handling, installing and maintaining consumablesproperly can minimize downtime and costs. […]

- Consumables for Robotic WeldingWhat you should know to improve performance and reduce costs When you invest in automation, the goal […]

- Detroit-Area Company Increases Productivity and Supports Lean Initiatives with New Robotic MIG GunThere are regular job shops. Then there are job shops that go far beyond basic fabrication — […]

- Don’t Let Consumables Consume Your ProfitsMIG gun consumables play a crucial and frequently overlooked role in MIG welding productivity and quality. Carefully […]

- Choosing Wisely Simple Ways to Save Money and Reduce DowntimeSelecting the right MIG gun consumable for your applications can help minimize downtime and reduce cost Everyone […]

- Keeping an Open Mind and Reaping the BenefitsWelding operator Brian Hubbard uses the 400-amp Q-Gun MIG gun with Centerfire consumables to complete welds on […]

- MIG Gun Consumables: Tips to Extend LifeConsumables for the welding gun can significantly impact the productivity and welding quality in an operation. This […]

- Tips for Improving MIG WeldingMaintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take […]

- How to Prevent Common Causes of Poor Welding Wire FeedingPoor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source […]

- How to Successfully Implement a Robotic Welding SystemIn today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: […]

- Improving Welding Automation Safety With Risk Assessment and TrainingDownload10 Tips for Robotic Welding Safety Robotic welding systems continue to gain in popularity due to their ability to […]

- Optimizing Shielding Gas Performance in MIG WeldingUsing the wrong shielding gas for MIG welding applications — or having improper gas flow — can significantly impact weld quality, […]

- MIG Welding Basics: Techniques and Tips for SuccessIt’s important for new welding operators to establish proper MIG techniques in order to achieve good weld quality and […]

- Implementing Robotic Welding: What to Know to Be SuccessfulThe potential advantages of robotic welding are well known — increased productivity, improved quality and greater cost savings compared […]

- Preventive Maintenance for Reamers, Accessories and Other PeripheralsFrom reamers or nozzle cleaning stations to wire cutters and anti-spatter sprayers, welding peripherals and accessories can contribute significantly […]

- Robotic Welding: Troubleshooting FAQsEvery operation wants to avoid downtime, as well as the cost for troubleshooting problems in the robotic welding cell. […]

- 7 Tips for Implementing a Robotic Welding CellImplementing robotic welding can significantly improve a manufacturing operation’s productivity and weld quality, but what are the robotic welding […]

- MIG Welding FAQs AnsweredMIG welding, like any other process, takes practice to refine your skills. For those newer to it, building some […]

- 5 Common Failures in Robotic Welding and How to Prevent ThemAvoiding common failures is often a matter of proper weld cell setup and robot maintenance, in addition to following […]

- Anti-Spatter Sprayer: How to See the Best ResultsWhen using anti-spatter liquid in a robotic weld cell, there are steps you can take to optimize the application […]

- How to Select and Use Anti-Spatter LiquidHaving the right products for your welding application impacts quality and productivity. Anti-spatter liquid is no exception. When selecting […]

- Spatter in Welding: Should You Consider Anti-Spatter Liquid?Are you losing money and arc-on time for excessive contact tip changeovers? Anti-spatter liquid may be an option to […]

- Ethernet vs. Standard Reamer: Making the SelectionUptime is key in any robotic welding system. Not only does it help companies increase productivity, but it also […]

- 7 MIG Welding Mistakes and How to Avoid ThemMIG welding offers numerous benefits for productivity without sacrificing quality of the finished weld, but there are many factors […]

- Proper Ergonomics Improve Welding Productivity, Protect WeldersBy Jack Kester, senior VP, Marsh Risk Consulting and Andy Monk, product manager, Bernard What is ergonomics? While this […]

- Tips to Optimize the Robotic Weld CellA pre-engineered robotic welding cell is designed for welding specific parts in a certain size range. These cells offer […]

- Signs Your MIG Gun Is Overheating – and How to Prevent ItAn overheated MIG gun can result in downtime, wasted consumables and lower productivity — costing a company more time […]

- Reduce Costly Downtime By Preventing Poor Wire FeedingIn welding, poor wire feeding is a common challenge — one that can be extremely costly for an operation […]

- Solving Five Causes of Downtime in a Robotic Welding OperationEnsuring a robotic welding cell stays productive and consistently generates a positive return on investment is determined, in large […]

- Gain Efficiencies and Extend Consumable Life with Anti-Spatter CompoundWhen it comes to robotic welding operations, uptime is key. Minimizing air movements and ensuring consistent workflow are just […]

- Tips for Optimizing Reamer UsageA nozzle cleaning station, or reamer, is a peripheral that can be integrated into an automated welding system to […]

- Getting the Most Out of PeripheralsA nozzle cleaning station or reamer removes spatter from the robotic MIG gun nozzle and clears away the debris […]

- What You Should Know About Robotic MIG Gun ClutchesImplementing and operating a robotic welding system requires attention to detail to gain high productivity and consistent quality. It’s […]

- 7 Tips for Improving MIG WeldingWant to improve your MIG welding? By following these seven tips, you can take your MIG welding operation to […]

- Best Practices and Troubleshooting Tips to Optimize Robotic WeldingCompanies invest in robotic welding systems to improve productivity, gain more consistent weld quality and reduce costs. Robotic welding […]

- Robotic Welding Can Offer Benefits for Smaller ShopsWelding automation offers numerous benefits for companies of all sizes — from improved productivity and weld consistency to lower […]

- 4 Strategies for Improving Throughput in Robotic Welding ApplicationsRobotic welding systems can provide many companies with increased productivity, improved quality and reduced costs — important and differentiating […]

- 5 Common Myths About Robotic Welding SystemsRobotic welding systems provide speed, accuracy and repeatability in many fabrication and manufacturing applications — features that can increase […]

- Top Things to Teach a Robotic Welding SupervisorWhether it’s in a small fabrication shop or a large manufacturing facility, investing in a robotic welding system is […]

- From Technology to Technical Support: Welding in Today’s Automotive IndustryA large part of maintaining productivity in an automotive application is ensuring high levels of uptime in the robotic […]

- 7 Ways to Save Money on Robotic WeldingRobotic welding systems have become an increasingly practical way for companies, large and small, to gain a competitive edge. […]

- What You Should Know About Shielding GasSometimes overlooked as a factor in weld quality and productivity, shielding gas can play a significant role in improving […]

- 7 Things To Know About Robotic Welding SystemsImplementing a robotic welding system isn’t something that happens on a whim — at least not successfully. Converting to […]

- What You Must Know About Robotic WeldingIn the fabrication and manufacturing world, quality and productivity are everything. To remain competitive, companies need to look continually […]

- FAQs About Robotic Peripherals AnsweredUsing peripherals can add significantly to the ROI a company achieves with its welding robots. Automated welding systems add […]

- Answers to Frequently Asked Questions About Welding AutomationRobotic welding systems, when implemented properly and for the right application, can add great value to a welding operation. […]

- A Guide to Troubleshooting Common GMAW Gun and Conusmable ProblemsA Guide to Troubleshooting Common GMAW Gun and Consumable Problems High quality MIG guns and consumables will breakdown more […]

- Good GMAW Welds Begin with Good, Well-Maintained EquipmentIt might at times seem like alchemy, but in fact there is nothing mysterious or magical about making a […]

- The Road to Welding AutomationWhy and When to Take the Journey Today, more companies than ever are automating portions, if not the entirety […]

- Learn How Peripherals Can Maximize Your Robotic Welding PerformanceLearn How Peripherals Can Maximize Your Robotic Welding Performance A nozzle cleaning station can lengthenthe life of the robotic […]

- Is Automation Right for Your OperationConsiderations to Make Before Investing Many manufacturers believe that converting their semi-automatic welding processes to a fast, productive, fully […]

- 5 Tips for Improving Robotic WeldingThe robotic MIG gun, consumables and wire can have a significant impact on welding uptime and productivity. Be certain […]

- Automated Intelligence: Deciding Whether Automation is Right For YouDeciding Whether Automation is Right For You Automated welding systems have the potential to increase productivity, improve weld quality, […]

- Troubleshooting Robotic WeldingTroubleshooting Robotic Welding When a problem occurs with a robotic weldingsystem, it is critical to identify the problemas quickly […]

- Should You Automate?Considerations for Making the Decision Investing in an automated welding system can provide companieswith a competitive advantage by providing […]

- Is Poor Conductivity Impeding Your Welding PerformanceMost people understand that the electrical circuit is at the heart of the welding operation. What you might not […]

- The Basics: MIG TroubleshootingLike any welding process, MIG welding has its complications. Even so, there is no reason to let common problems […]

- Thoughts for Improving Welding Operations in Today’s Automotive IndustryThoughts for Improving Welding Operations in Today’s Automotive Industry Worldwide, companies serving the automotive industry have faced a unique […]

- Addressing Welding Challenges in Today’s Automotive IndustryThe automotive industry has certainly begun to show signs of rebounding from the economic downturn; however, companies are now […]

- MIG Welding Shielding Gas BasicsShielding gas can play a significant role in improving, or impeding welding performance. MIG (GMAW) welding with shielding gas […]

- The Causes of GMAW FlawsProperly identifying the cause of weld flaws and implementing the correct cures can help welding operators minimize downtime and […]

- 10 Mistakes in Running a Welding Operation and How to Fix ThemMistakes in the welding operation are not uncommon, but many of them can have a significant impact on quality, […]

- Stay Cool When Welding In The Summer HeatIt’s tough to stay cool in the hot summer months, let alone when you are “under the hood” welding. […]

- Teaching New Welders to Improve Quality and ProductivityFor companies faced with training new welders, it is important to instill good habits early in the process. Doing […]

- Customer Testimony | Tico Adopts Bernard MIG Welding Guns & ConsumablesUsing Bernard® Q-Gun™ semi-automatic air-cooled MIG guns and Centerfire™ consumables, Tico Terminal Trucks and Trailers improved productivity and […]

- Customer Testimony | Jolson Welding Discusses Bernard MIG Guns, Flux-Cored Guns and Welding ConsumablesBob Jolson, owner of Jolson Welding, discusses the benefits of Bernard’s Q-Gun™ semi-automatic air-cooled MIG gun, Dura-Flux™ self-shielded […]

- Customer Testimony | MIG Welding with Bernard Centerfire ConsumablesBob Jolson, owner of Jolson Welding, talks about the benefits of Bernard’s Centerfire™ consumables.

- Customer Testimony | Flux-Cored Welding with a Bernard Dura-Flux GunBob Jolson, owner of Jolson Welding, talks about why he swears by the Bernard® Dura-Flux™ self-shielded flux-cored gun.

- Customer Testimony | Graham Corporation Adopts Bernard MIG Guns and ConsumablesLearn what Graham Corporation has to say about Bernard® MIG guns and consumables.

- Customer Testimony | Bernard MIG Welding Consumables Save Time and Last LongerBernard® MIG welding consumables help Taylor Machine Works save time by reducing contact tip changeover in its forklift […]

- Customer Testimony | Bernard Replaceable MIG Gun Parts Save Money, Improve PerformanceTaylor Machine Works saves money by welding its forklifts with Bernard® MIG guns — all parts are replaceable, […]

- Customer Testimony | Welding students in Tulsa benefit from Bernard MIG guns and consumablesTulsa Welding School’s Houston campus needs reliable equipment that can handle any process. Bernard® MIG guns and consumables […]

- Customer Testimony | Blinn Instructors Choose Bernard MIG Guns and Consumables for Dependable Welding EquipmentBlinn College welding school instructors and students agree – Bernard® MIG guns and consumables are the welder’s best […]

- Video | Bernard Centerfire Changing Consumables ChallengeWatch as we compare the time it take to change Bernard® Centerfire™ consumables on our BTB MIG Gun […]

- Video | Bernard BTB MIG Gun Handle Impact TestWatch as we compare the strength of our Bernard® BTB semi-automatic air-cooled MIG gun handle to those of […]

- Animation | Bernard Clean Air Fume Extraction MIG Welding GunsFor a cleaner, more compliant work environment, get right to the source and extract fumes at the weld […]

- Animation | Bernard BTB Semi-Automatic Air-Cooled MIG Welding GunsBuild your ultimate MIG gun. Choose from a variety of necks, handles and trigger styles to optimize welder […]

- Video | Configure your Bernard Semi-Automatic MIG Gun OnlineNow mobile friendly! Configure your Bernard® semi-automatic MIG gun – anytime, anywhere! We recognize that welding applications differ […]

- Video | Bernard AccuLock S Consumables for the Inexperienced WeldersAs you support more inexperienced welders, choosing equipment with fewer points of failure and simplified maintenance can reduce […]

- Video | Bernard AccuLock S Consumables for Better ProductivityMeet Sam, a semi-automatic MIG Welding Supervisor at an Industrial Company. Sam’s faced with increasing manufacturing growth putting […]

- Animation | Bernard AccuLock S Consumables No Measuring RequiredChallenged by increasing welder retirements and turnover while orders keep growing year over year? As you support more […]

- Animation | Bernard AccuLock S Consumables Dual Locked LinerBernard® AccuLock™ S liners are locked and concentrically aligned to both the contact tip and the power pin […]

- How to Choose MIG Welding Gun PartsIn addition to the amperage of MIG welding gun you choose, the MIG gun parts — cable, neck […]

- Configuring a MIG Welding Gun for Your ApplicationHave you struggled to gain proper joint access when welding? Or found yourself fatigued at the end of […]

- Taylor Forklift Operation Reduces Downtime, Costs with BernardTaylor Machine Works Inc. has spent over 90 years building a reputation by engineering and producing exactly what […]

- Self-Shielded Flux-Cored Welding: Choosing Your GunFor structural applications, some contractors have made the switch from stick welding to self-shielded flux-cored welding to increase […]

- Fume Extraction Gun: Features and Techniques to Improve PerformanceLimiting exposure to welding fumes is an increasingly important issue for many welding operations, as it provides a […]

- Managing MIG Guns and Consumables for Multiple ApplicationsUnderstanding how to pair the best gun and consumable with the job can pay off in workflow and […]

- How Can Customizing a MIG Gun Benefit the Welding OperationCustomizing a MIG gun for the needs of your specific application can pay off in greater productivity, better […]

- Tips for Maximizing Welding Operator Comfort and ProductivityBeing as comfortable as possible contributes to welding operator safety and productivity — and it’s a factor that […]

- Understanding Gun Ratings: What You Need to Know to Select Your MIG GunSelecting “too much” gun can increase fatigue and decrease your productivity. The ideal MIG gun strikes a balance […]

- Customizing Your GMAW Gun for the JobThe heat and repetitive motions that accompany gas metal arc welding (GMAW) can take their toll. Customizing your […]

- Common Causes and Solutions to GMAW Gun OverheatingWhen choosing a gas metal arc welding (GMAW) gun, there are several factors to consider. After all, welding […]

- Preventive Maintenance Helps Optimize MIG Gun PerformancePlanned downtime for preventive maintenance in the welding operation is not time wasted. Rather, it is a crucial […]

- Criteria for Selecting a MIG GunTo maximize the benefits of MIG welding, it is imperative to select the right MIG gun for the […]

- Proper Storage of MIG Guns and ConsumablesAs with any piece of equipment in the shop or on the jobsite, proper storage and care of […]

- What’s Changing? Trends in Semi-Automatic MIG GunsThere are many considerations that factor into a company’s ability to achieve the best quality and highest productivity […]

- Money-Saving Tips for MIG GunsConsider these money-saving tips for MIG guns as a good first step to keeping this equipment running longer […]

- Which is the Right MIG Gun? Tips for Making the SelectionWhen it comes to welding, no two applications are alike. Just as it’s important to select a power […]

- Tips for Making a MIG Gun Last on the JobsiteCarefully selecting and properly maintaining a welding gun on a jobsite can help improve quality and productivity, while […]

- Selecting the Right Gun for MIG Welding Is Key to Achieving the Best ResultsSelecting the right gun for the job is important to achieving good results and realizing the benefits MIG […]

- Gain Comfort, Productivity with the Right Welding EquipmentA welding gun’s handle, neck and power cable design all can significantly impact the duration of time a […]

- Premier Boat Fabricator Improves Productivity 25 Percent with New MIG Guns and ConsumablesWhen 90 percent of your business focuses on boat fabrication and repairs that require you to meet specific […]

- Attacking Weld Fume at the SourceFume extraction guns can help companiesmaintain compliance with safety regulationsand create a cleaner, more comfortable weldingenvironment. Proper use […]

- Emergency Vehicle Service Provider Gains Versatility, Comfort and More from New Welding MIG GunsWelding operators at True North Emergency Equipment weld on a variety of materials and at a variety of […]

- 10 Money Saving Tips for Your Semi-Automatic MIG GunsYour welding operation, just like any other portion of your business, offers opportunities to conserve resources. Consider these […]

- Fume Extraction Guns: Understanding the BasicsNew industry standards from the Occupational Safety and Health Administration (OSHA) and other safety regulatory bodies have been […]

- The Value of Comfort: Gaining Productivity with the Right Welding GunThe term “ergonomics” has become increasingly common in the workplace as companies strive to improve safety and efficiency […]

- Miller Welding and Machine Turns to Bernard for MIG Guns and ConsumablesMiller Welding and Machine Turns to Bernard for MIG Guns and Consumables Standardizing on Bernard Centerfire consumables and […]

- Simple Tips for Getting the Most from Your MIG EquipmentSimple Tips for Getting the Most from your MIG Equipment Proper gun and consumables maintenance will help ensure […]

- Which Semi-Automatic MIG Gun is Right for the Job?Selecting the right gun for the job is an important way to gain good weld quality and productivity. […]

- Strong Bond and Strong Community at San Diego Continuing EducationThe economy is in bad shape right now, but when it improves, the graduates of San Diego Continuing […]

- Air-Cooled vs. Water-Cooled MIG Gun: Which is Right for YouFor some companies, choosing between an air-cooled or a water-cooled MIG welding system is pretty cut and dry. […]

- Avoid These 5 MIG Gun Myths to Optimize PerformanceMIG guns and consumables are sometimes an afterthought when purchasing a welding system, but considering that they are […]

- Finding a MIG Gun That FitsChoosing the right MIG gun can have a big impact on your comfort level and muscle fatigue throughout […]

- Maintaining Your MIG Gun… and Your Welding CostsSelecting the right MIG gun for your welding application, and maintaining it properly, is just as important to […]

- Three Ways Welding Guns and Consumables Can Improve ProductivityHaving nozzles that provide consistent shielding gas coverage is imperative to preventing defects like porosity. Here, Brooklyn Iron […]

- GMAW Guns, Consumables and More – Common Questions AnsweredGas metal arc welding (GMAW) involves more than just arc-on time. Welding operators also need to be mindful […]

- Customer Testimony | MIG Welding with a Bernard Q-Gun MIG GunContractor Bob Jolson talks about how Bernard’s Q-Gun™ semi-automatic air-cooled MIG gun has increased his productivity and reduced […]

- Customer Testimony | Contractor Shares Benefits of Bernard Dura-Flux Self-Shielded Flux-Cored GunJolson Welding (Wheatland, Calif.) relies on the durability and comfort of the Bernard® Dura-Flux™ self-shielded flux-cored gun for […]

- Best Practices for Success in Self-Shielded Flux-Cored WeldingSelf-shielded flux-cored arc welding (FCAW-S) offers numerous benefits, including good weldability, high deposition rates, and excellent chemical and […]

- Jolson WeldingJolson Welding deals in heavy steel. The company specializes in structural welding for bridge and highway work in […]

- Handrails in Hell, ArizonaHot Az Hell Welding and Fabrication puts the Dura-Flux gun to the test on a daily basis building […]

- Contractor increases productivity…From left to right, Bob and Colleen Jolson, owners of Jolson Welding, and welder, Brandon Hobbs, have experienced […]

- Tips For Avoiding Common Flux-Cored Problems & Improving Your FCAW WeldsFlux-cored welding offers many advantages when welding on construction applications, including high disposition rates, and good chemical and […]

- Your FAQs About FCAW…Learning how to identify and resolve problems quickly can help improve your self-shielded FCAW performance and save you […]

- Video | Tregaskiss QUICK LOAD Liner Replacement RaceTregaskiss QUICK LOAD Liner Replacement Race Have you ever timed the difference between changing a rear-loading liner and […]

- Animation | Tregaskiss QUICK LOAD Liner AutoLength SystemChanging a conventional liner can cost you in more ways than one. The Tregaskiss® QUICK LOAD® liner AutoLength™ […]

- Animation | TOUGH GUN TA3 Robotic Air-Cooled MIG Welding GunsDesigned with our unique and durable low-stress robotic (LSR) unicable, TOUGH GUN® TA3 robotic air-cooled MIG guns feed […]

- Animation | Tregaskiss Fixed Automatic MIG GunsTregaskiss® fixed automatic MIG guns are engineered for hard tooling automation applications requiring a simple, durable and repeatable […]

- Video | Tregaskiss Fixed Automatic MIG GunsTregaskiss® fixed automatic MIG guns are engineered for hard tooling automation applications requiring a simple, durable and repeatable […]

- Animation | Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning StationsAutomating spatter removal helps to extend the life of your robotic MIG welding guns and consumables, benefiting your […]

- Video | Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning StationsThe Tregaskiss® TOUGH GUN® TT3 reamer is TOUGH on spatter and operates reliably in even the harshest welding […]

- Video | Tregaskiss AccuLock R Consumables for Better ThroughputTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related […]

- Video | Tregaskiss AccuLock HDP Contact TipsTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related […]

- Animation | Tregaskiss AccuLock R ConsumablesTregaskiss® AccuLock™ R consumables are designed for increased tip life, which can reduce your replacement frequency and related […]

- Video | Configure your Tregaskiss Robotic MIG Gun and Reamer OnlineTregaskiss is making it easier for you to get the exact MIG gun you need — Now you […]

- Selecting Contact Tips for Robotic WeldingContact tips are often referred to as the smallest fuse in the fuse box that is your robotic […]

- How Robotic Welding Supervisors Can Improve the OperationGaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a […]

- Best Practices for Robotic Welding SupervisorsWith careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, […]

- Understanding Fixed Automatic Welding GunsFixed automation welding is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment […]

- 5 Misconceptions About Robotic Welding Guns and ConsumablesRobotic MIG welding guns and consumables are an important part of the welding operation yet are frequently overlooked […]

- Reduce Downtime and Costs with Water-Cooled Robotic MIG GunsFor many fabricators, the choice between an air-cooled and water-cooled robotic MIG welding gun is easy. Their heavy-duty […]

- Maintaining TCP: How Does Your Robotic MIG Gun Neck Factor In?The durability of the gun neck — and especially its ability to withstand impacts — is important for […]

- What to Know About Liners for Robotic Welding GunsThe liners used in a robotic gas metal arc welding (GMAW) gun play a significant role in the […]

- Choose the Right Power Cable to Reduce Downtime in Robotic Welding ApplicationsIn robotic MIG welding applications, minimizing downtime is key. It reduces costs and improves efficiencies to help an […]

- Conventional Guns on Through-Arm Robotic Welding Systems: When to Make the ChoiceWhile the choice of gun is sometimes an afterthought, it can significantly impact efficiency, throughput and quality of […]

- Six Tips for Implementing Your Robotic GMAW Gun… and Getting the Most From ItAs companies seek to gain a competitive edge, it’s not surprising that some turn to welding automation. It […]

- Through-Arm Robotic MIG Guns: Top 10 Things to ConsiderTo gain the advantages of a through-arm robotic MIG gun, it is important to carefully select and maintain […]

- Optimizing the Robotic Welding Process with the Right GMAW GunAs companies seek out means to increase productivity and improve quality, the investment in welding automation continues to […]

- Water-Cooled Robotic MIG Guns Can Reduce Consumable Costs and DowntimeFor some fabricators, the choice between an air-cooled or a water-cooled robotic MIG welding gun is simple. Some […]

- Trends Associated with Robotic Welding GunsManufacturing and fabrication environments are dynamic, ever changing with the economy, customer demands, available labor and skill sets, […]

- 5 Things to Know About Robotic MIG GunsConsider some of the top things to know about robotic MIG guns as a way to get the […]

- Equipment, Training, Maintenance and More: Best Practices for Successful Robotic WeldingThe cost to implement welding automation can be substantial, requiring companies to plan out the purchase carefully and […]

- Tips for Selecting the Right Robotic MIG GunChoosing the proper robotic MIG gun is essential for optimizing welding automation, and it can help ensure good […]

- Optional Robotic MIG Gun Features Can Improve Quality and Reduce DowntimeOptimizing the performance of a robotic MIG gun can help improve weld quality and reduce downtime in the […]

- Preventive Robotic MIG Gun Maintenance: the Whos, Whens, Whys and HowsRegular maintenance of the robotic MIG gun can help provide a positive return on an automated welding investment. […]

- Preventive Maintenance Isn’t Just for Welding RobotsInvesting in welding automation can be a relatively quick way for companies to achieve greater productivity, improve weld […]

- Hybrid Robotic MIG Gun Adds to Automation Benefits for Phoenix-Based CompanyWhen your company focuses on custom contract manufacturing, you have to be prepared for any job that comes […]

- Simple Ways to Protect Your Robotic MIG Gunand Your Overall Investment in Automation Given that the single-most enticing reason for companies to invest in welding […]

- Choosing the Right Robotic Gun for MIG ApplicationsSelecting the right robotic MIG gun,including an air-cooled model (as shownhere), can help ensure good weld quality,and reduce […]

- Selecting, Installing and Maintaining a Through-Arm Robotic MIG GunTo gain the advantages of a through-armrobotic MIG gun, it is important tocarefully select and maintain the gun,and […]

- Is it Time to Automate? 5 Factors to Consider5 Five Factors to Consider Making the decision to automate your welding process isn’t something to be taken […]