7 Ways to Save Money on Robotic Welding

Robotic welding systems have become an increasingly practical way for companies, large and small, to gain a competitive edge. Assistance with everything from planning and implementation to training is readily available through robotic integrators or vendors, helping make the capital investment less risky and allowing companies to safeguard better results.

In addition to programming the robot in a manner that ensures the accuracy, speed and repeatability needed to complete high-quality welds, there are also several steps that companies can take to increase the return on their investment. Saving money on the robotic welding systems is, after all, one of the primary reasons — apart from productivity gains and quality improvements — for implementing this technology.

Minimizing downtime, reducing the need for parts replacements and preventing rework are among the more important cost-saving steps companies can make. Here are some ways to achieve those goals.

Tip No. 1: Add peripherals

Peripherals — reamers, wire cutters, neck inspection tools and clutches or solid mounts — are all additional equipment that can protect the robotic welding system investment, maximize its effectiveness and reduce costs. This equipment is particularly helpful in minimizing downtime that leads to offline maintenance or repairs of the equipment or its components (e.g., the robotic MIG gun, cables or consumables).

Unfortunately, some companies view this equipment as an unnecessary cost and don’t realize that they can play an important role in improving quality and increasing productivity. Peripherals do, of course, require an up-front investment, but the payback period is relatively short.

For example, a reamer (also called a nozzle cleaning station or spatter cleaner) minimizes spatter build-up in the nozzle and with it the opportunity for electrical resistance that could lead to premature failure of the robotic MIG gun or consumables. Failure of the gun or the consumable, of course, increases the cost for replacements and requires downtime for changeover — downtime that puts the robot offline and stops it from making parts … and making money.

A clean nozzle also allows for good shielding gas flow, thereby minimizing quality issues that could be costly to repair.

Tip No. 2: Manage and maintain your consumables properly

To protect consumables against costly damage before even placing them on the robotic MIG gun, it is important to employ proper storage and handling practices.

Always keep consumables in their original packaging until they are ready for use. Opening the packaging and placing these components in a bin can lead to scratches or dents, both factors that allow spatter to adhere the product and can lead to premature failure. Similarly, removing contact tips or retaining heads from their packaging and storing them in open or dirty containers can cause dirt and/or oil to accumulate on them, which can lead them to seat improperly together.

Regularly check that the contact tips, retaining heads and nozzles are securely connected. Solid connections help ensure reliable electrical conductivity and minimize heat, in turn providing more consistent weld quality and helping the consumables last longer.

In addition, always follow the MIG consumable manufacturer’s suggestions for installing these consumables and use the proper tools in order to gain the best performance and reduce the risk of damaging them.

While these two practices may seem simple, they can go a long way toward minimizing product replacements and preventing downtime that keeps the robot from reaching its optimal throughput during a shift. Both have measurable costs associated with them, as well, and can help companies save money.

Tip No. 3: Implement a preventive maintenance program

Preventive maintenance (PM) is another critical way to save money on robotic welding, primarily by preventing unscheduled downtime, poor quality parts and/or costly repairs. It can even help prevent failures that require equipment replacements. The robot, as well as the robotic MIG gun, consumables and cables can all benefit, too.

Schedule time to check connections throughout the system (from the front-end consumables through the gun and power pin). This task can easily take place during routine pauses in welding cycles to prevent unplanned downtime. To prevent debris build-up that may affect part fit-up, also remember to clean fixturing on a regular basis. Similarly, check the front-end consumables for spatter build-up and replace as necessary.

Verifying tool center point (TCP) is another important cost-saving measure, as it helps ensure that the robotic welding system continues to operate within its proper parameters and provide the same consistent weld quality — repeatedly.

Certain maintenance can occur in between shifts, such as cleaning off the robot or changing consumables, for example. Other activities, such as greasing the robot’s joints usually occur less frequently and during a longer scheduled stop. Companies should assess their individual needs and plan the preventive maintenance schedule accordingly. For larger companies, hiring a maintenance crew to take care of preventive maintenance may be desirable.

Tip No. 4: Use the best filler metal package for the job

Reducing downtime for routine filler metal package changeovers can be one of the most effective ways of maximizing return on investment and productivity. Ideally, select a package that is large enough to minimize wire changeovers, but not so large that the same wire will remain on the shop floor for more than a couple of days. Filler metal manufacturers typically ship their products in airtight or hermetically sealed containers. Once opened, the wire is at risk of absorbing moisture, dust, oil or other contaminants that can affect its welding performance and ultimately cost money to replace, not to mention downtime to change over.

It’s also important to consider the type of filler metal package being used. For instance, recyclable filler metal packaging can reduce costs and labor for properly separating and disposing of recyclable and non-recyclable packaging materials.

When possible, stocking an extra filler metal package near the robot can also contribute to cost savings by reducing downtime to transport a new package from the storage area to the weld cell.

Tip No. 5: Select, trim and install the right MIG gun liner

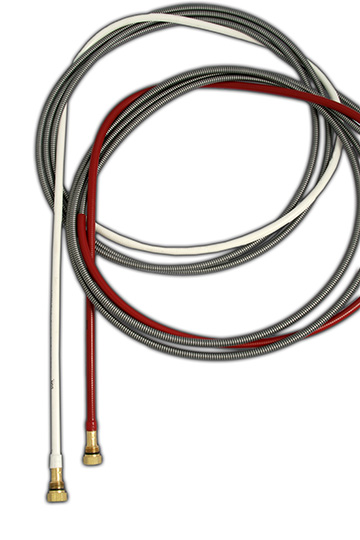

To prevent problems like bird-nesting (a tangle of wire in the drive rolls) or poor wire feeding — both issues that lead to downtime and added costs — it is important to select the right MIG gun liner and install it properly.

Always make sure to have the correct diameter liner for the wire being used. Using too large of a liner for too small of a wire may allow the wire to wander, causing poor wire feeding and/or premature liner failure due to excessive wear. Similarly, if a liner is too small for the wire diameter, the wire will not be able to feed smoothly, resulting in poor weld quality and potentially a clogged liner.

Tip No. 6: Select the appropriate MIG gun

Trimming the liner to the correct length is also a good cost-saving measure, since it helps prevent downtime and costs for replacing this part. Some manufacturers print markings on the outside of the weld cable to show when the cable is twisted, providing welding operators the opportunity to straighten it fully in order to measure for the correct liner length. Other manufacturers offer liner gauges as a guide. Both work well to guide in the correct trimming process. There are also spring-loaded modules available that work in conjunction with a front-loading liner to help minimize issues if a welding operator cuts the liner to an incorrect length. These modules are housed in the power pin and put forward pressure on the liner after the welding operator installs it from the front of the gun. They allow up to 1 inch of forgiveness if the liner is too short.

Having the right style and amperage MIG gun for the application can help minimize downtime for overheating and potential failure of this equipment. It can also save money by preventing the purchase of a larger (and more costly) gun than necessary for the job.

Air-cooled robotic MIG guns (rated at 500 amps) operate comfortably in the range of 200 to 300 amps at approximately 60 percent duty cycle with mixed gases. They are good for welding thinner materials — typically upwards of 4 mm thick. The cost of ownership for these guns is usually relatively low since they are easier to maintain and replacement parts are less expensive than water-cooled guns. They work well for shorter welds on high-volume applications and are quite durable, especially through the neck. This durability further reduces costs because it helps the guns maintain their accuracy and create consistent welds.

For higher-amperage applications, applications with thicker materials (1/4-inch or more) or those requiring prolonged welding, it’s necessary to have a gun capable of withstanding the increased heat. A water-cooled MIG gun offering 300 to 600 amps of power and 60 to 100 percent duty cycle is a good option to help reduce costs by preventing gun failure or downtime for overheating. These guns cost more to maintain, however, so it’s important to implement a good PM program for them to avoid any costly surprises.

Hybrid robotic MIG guns are another option to help reduce costs, particularly when it comes to maintenance. These guns are a mix between an air-cooled and a water-cooled gun, and feature water lines that run independently of the power cable, making them more accessible to repair than on a standard water-cooled MIG gun. These guns can also remain on the robot for maintenance, too, which reduces downtime for removal. Plus, if there are issues with water circulation, these guns can rely on an underlying air-cooled unicable to provide enough current-carrying capacity to avoid a catastrophic failure such as destroying a power cable or other components.

Tip No. 7: Take advantage of training opportunities

Many robotic integrators offer training opportunities not just up front, but also throughout the course of ownership of the robotic welding cell. Because robotic welding systems require properly trained operators to oversee them, it is important to make sure these individuals continue to gain knowledge that will increase their programming, troubleshooting and preventive maintenance knowledge and skills. In many cases, robotic integrators offer online tutorials, troubleshooting information and/or additional on-site training as aftercare support. By taking advantage of such opportunities, it will be easier for those who oversee the robotic welding cell to act quickly should a problem result and get the robot back online to product parts. It also empowers them to take preventive care to prevent downtime in the first place.