Lubricator

This dedicated motor lubricator maximizes performance and protects your TOUGH GUN reamer investment by extending the life of the motor, and is highly recommended for use in damp and moisture rich environments. Factory set for optimal pneumatic oil lubrication, the lubricator is available as an option when configuring your new unit* or is retrofittable to your existing TOUGH GUN TT3E reamer.

*Ordering your new TOUGH GUN reamer with the factory-installed lubricator option increases your warranty from 1 to 2 years, or increase your warranty to 3 years with the factory-installed lubricator option plus exclusive use of TOUGH GARD® anti-spatter liquid.

Filter / Regulator

The Filter / Regulator unit from Tregaskiss is another recommended accessory that helps extend the life of your TOUGH GUN reamer. The filter cleans the air supply to the reamer and restricts debris from reaching the motor, keeping it uncontaminated and ensuring maximum performance and longer life, while the regulator works to ensure optimal air pressure is achieved at the unit.

Spray Containment

The innovative spray containment unit from Tregaskiss helps prevent air contamination by catching anti-spatter overspray in its sealed basin, improving the air quality of the working environment and maintaining the cleanliness of the weld cell. Click here to learn more.

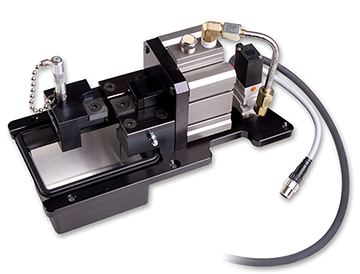

TOUGH GUN Wire Cutter

The TOUGH GUN wire cutter removes the ball-end of the welding wire to provide smooth arc starts and consistent wire stick-out. The TOUGH GUN wire cutter easily cuts a variety of wire types from stainless steel to aluminum to flux-core in wire sizes up to 1/16″. Click here for more information.

Nozzle Detection

Nozzle detection for the TOUGH GUN TT3E reamer uses a proximity sensor mounted on the side of the reamer that can be used independently of the ream cycle. The robot positions the front end of the MIG gun close to the sensor to detect the presence of the nozzle. If the nozzle is present, a signal is then sent back to the robot controller or PLC. Learn more about the nozzle detection system.

Tregaskiss Cutter Blades

Improved performance. Competitive pricing.

Tregaskiss is pleased to announce improvements to the design of our cutter blades. These new cutter blades are engineered from harder, stronger material for enhanced performance and durability, making them more resistant against breaking, snapping, chipping or cracking. Click here to find out more.

Tregaskiss V-Blocks

Compatible with Tregaskiss® and most competitive consumables, these four-sided v-blocks ensure your cutter is concentric with your consumables and your nozzle bore to guarantee the most effective ream. Choose from five available v-block options when configuring your new TOUGH GUN TT3 reamer.

TOUGH GUN Reamer Stand

Custom Height. Quick Installation. Easy on the budget.

Tregaskiss provides a simple fixed height durable stand for all TOUGH GUN TT3 and TT3E reamer models. Each TOUGH GUN reamer stand can be ordered to a custom height between 18- and 45-inches. Click here to learn more.

TOUGH GARD Anti-Spatter Liquid

TOUGH GARD anti-spatter liquid was developed to address the performance requirements of metal fabricators. TOUGH GARD anti-spatter liquid won’t harm machinery or clog the sprayer like oil-based anti-spatter solutions, it cleans up easily with no residue, it’s safe to use and it’s safe for the environment. Helping prevent spatter adhesion and extending the life of consumables, TOUGH GARD anti-spatter liquid reduces downtime thus lowering operating and maintenance costs. Click here to learn more.

TOUGH GARD Multi-Feed System

The TOUGH GARD multi-feed system for anti-spatter solution can connect up to ten TOUGH GUN TT3 reamer stations. This system eliminates the need to refill anti-spatter reservoirs on a frequent basis, resulting in lower operating costs, reduced downtime and increased safety. Click here for more information.