Selecting, Installing and Maintaining a Through-Arm Robotic MIG Gun

robotic MIG gun, it is important to

carefully select and maintain the gun,

and also to follow the manufacturer’s

instructions for installation.

Robotic welding systems are all about speed and repeatability. When implemented properly, they can help companies gain greater productivity and higher weld quality, while also lowering their costs and, in some cases, providing them with a competitive edge.

As with any welding equipment, robotic welding systems have undergone improvements in technology that build on those advantages. For instance, in recent years, the industry has begun to shift from conventional robots with over-the-arm robotic MIG guns to through-arm robots. These robots feature robotic MIG guns whose cable assembly, as the name suggests, runs through the arm of the robot. One significant advantage to this style of robotic MIG gun is its durability. Because the arm of the robot protects the power cable, the cable is less prone to wear from routine torsion, and it is protected from catching on fixturing or rubbing against the robot — all situations that can lead to premature failure.

Because they don’t require a mounting arm like conventional robotic MIG guns do, through-arm robotic MIG guns also provide a smaller work envelope. As a result, they are particularly well suited for applications that require access to tight spaces. The automotive industry, for example, often uses through-arm robots.

Just like any piece of welding equipment, however, through-arm robotic MIG guns require careful selection and maintenance. They also require a few precautions during the installation process.

Selection

Choosing a through-arm robotic MIG gun is much the same as choosing a conventional robotic MIG gun, with the exception of the power cable selection. These power cables are typically sold in predetermined lengths according to the make and model of the robot, as opposed to the varying cable lengths available for over-the-arm robots. Having set lengths helps minimize kinking of the cable within the arm of the robot and also helps simplify installation of the MIG gun. Always know your robot make and model when placing an order for a new gun.

When choosing a style of through-arm robotic MIG gun, look for one that offers good power cable rotation. For example, some manufacturers place a rotating power connection on the front of the cable that allows it to be rotated 360 degrees. This ability to rotate freely provides stress relief for the cable and power pin, and allows for greater maneuverability for a wider range of applications. It also helps prevent kinking that could lead to poor wire feeding, conductivity issues or premature wear or failure. Also, look for power cables constructed of durable components and materials to help prevent similar wear or failure.

It is also important to select the proper amperage of gun and be certain that it has the proper duty cycle for the given application. Most manufacturers offer guns up to 500 amps, in both air- and water-cooled models.

Finally, identify whether the robot has collision software or if the robotic MIG gun needs to be paired with a clutch to protect it in the event of a collision.

Installation

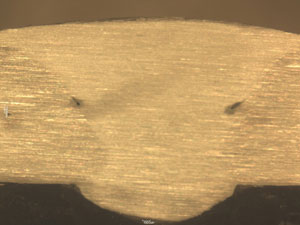

Installing a through-arm robotic MIG gun incorrectly can lead to a host of problems, not the least of which is cable failure. Incorrect installation can also cause weld quality issues, such as porosity due to poor electrical connections; premature consumable failure caused by poor conductivity and/or burnbacks; and potentially, failure of the entire robotic MIG gun.

To prevent such problems, it is imperative to consult the manufacturer’s instructions for each specific MIG gun. For through-arm robotic MIG guns, it is also important to note that the power cable needs to be installed in a slightly different manner than a conventional over-the-arm robotic MIG gun. Consider these guidelines.

When installing a through-arm robotic MIG gun, allow approximately

1.5 inches of slack to prevent undue stress on the power cable

and power pin, and minimize the opportunity for damage

to either component.

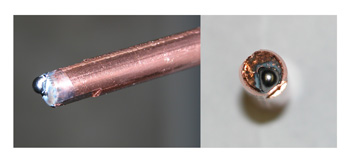

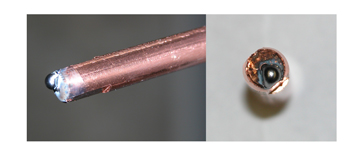

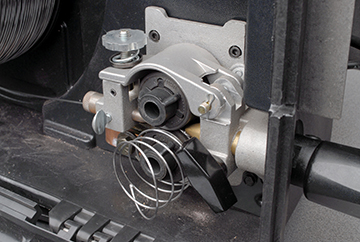

First, position the robot with the wrist and top axis at 180 degrees, parallel to each other. Install the insulating disc and spacer the same as with a conventional over-the-arm robotic MIG gun. Be certain that the power cable position is also correct. The cable should have the proper “lie” with the robot’s top axis at 180 degrees. It’s important to avoid a very taut power cable, as it can cause undue stress on the power pin. It can also cause damage to the cable once the welding current passes through it. For that reason, it’s important to make sure the power cable has approximately 1.5 inches of slack when installing it. (See Figure 1).

Secondly, the stud on the front of the power cable needs to be fully inserted into the front connector of the through-arm robotic MIG gun. To achieve this result, always install the stud into the front housing prior to bolting the front end onto the robot wrist. By pulling the cable through the wrist and making the connections in front of the gun, it’s easy to slide the whole assembly back (once the cable is fastened) and bolt it onto the wrist. This extra step will ensure the cable is seated and will allow for maximum continuity and maximum power cable life.

Also, be certain to position the wire feeder in close enough proximity that the power cable will not be stretched unnecessarily after installation. Having a wire feeder that is too far away for the length of the power cable can cause undue stress on the cable and front end components.

Maintenance

Consistent preventive maintenance is key to the longevity of any robotic MIG gun, including the through-arm style. During routine pauses in production, check for clean, secure connections between the MIG gun neck, the diffuser or retaining heads and the contact tip. Also, check that the nozzle is secure and any seals around it are in good condition. Having tight connections from the neck through the contact tip helps ensure a solid electrical flow throughout the gun and minimizes heat build-up that could cause premature failure, poor arc stability, quality issues and/or rework.

Check regularly that the welding cable leads are secured properly and assess the condition of the welding cable on the robotic MIG gun. Look for signs of wear, including small cracks or tears, and replace as necessary.

Spatter build-up can cause excessive heat in the consumables and MIG guns, and block shielding gas flow. Visually inspect consumables and the gun on a regular basis for signs of spatter. Clean the gun as needed and replace consumables as necessary. Adding a nozzle cleaning station (also called a reamer or spatter cleaner) to the weld cell can also help. Like its name implies, a nozzle cleaning station removes spatter (and other debris) that builds up in the nozzle and diffuser. Using this equipment in conjunction with a sprayer that applies an anti-spatter compound can further protect against spatter accumulation on the consumables and the through-arm robotic MIG gun.

In addition to implementing lean practices, which many manufacturers find can greatly improve productivity and quality, some may also choose to automate their welding operations as a means to gain a competitive edge or improve profitability. This decision, however, is not one to be taken lightly. While there are many advantages to automating your welding operation, implementing a new automated welding system first requires a careful assessment of the facility, the parts to be welded and your available labor. If you are wondering whether automating is right for you, consider some of the benefits of doing so, along with the many details that you should assess before proceeding. When implemented properly, and for the right application, an automated welding system can provide marked improvements in productivity over a semi-automatic welding process — an automated welding system is significantly more efficient and can provide the throughput of several manual welding stations. That does not mean that skilled welding operators are not required in an automated welding operation. On the contrary, they are a vital part of it. Other advantages of automated welding systems include lower labor costs, as well as excellent reliability and consistency in welding performance. In many cases, an automated welding system can provide companies with an attractive return on investment (ROI) and the opportunity to lower operational costs as well. Automated welding systems rely on accuracy and repeatability to provide the quality and productivity improvements for which they have been designed. To achieve these results, the parts that you have in your welding operation need also to be consistent and repeatable. Gaps, poor fit-up or poor joint access can easily prevent an automated welding system from doing its job correctly. Simple part designs, in particular, are good candidates for an automated welding system, as they allow the robot to execute the same weld repeatedly. If you are considering an automated welding system, you should also be certain that the part does not require intricate clamping or tooling to hold it in place. It is a good idea to have a robotic integrator or welding solutions provider assess your operation and the weldments (or parts) prior to implementing an automated welding system. Generally, automated welding systems are best for high-volume, low-variety applications; however, smaller facilities can still be good candidates for automation. Often, the low-volume, high-variety applications require flexible tooling and more programming to manage several products. The additional complexity may increase the initial investment but the efficiency and productivity improvements of automation can still provide a solid return on the initial investment. It is important to assess your current operation for process flow (or workflow) to determine whether investing in an automated welding system is the right choice. In some cases, your existing operation may have to be reconfigured in advance of automation to prevent bottlenecks that could slow down the movement of parts into the automated welding cell. There are several options available, including the technique of using “U-Shaped Cells” for dedicated products, or setting up a flexible cell that can manage quick tool and fixture changes. These are particularly helpful if your welding requirements change on a daily (or hourly) basis. Automated welding systems can significantly improve quality and reduce the occurrences of weld defects. In many cases, they can also improve weld cosmetics and minimize or eliminate spatter. That being said, you should have a dependable supply of quality components that enter the automated system. Quite simply, if poor quality parts go in to the cell then poor quality parts will come out of the weld cell. Further, a consistent and reliable supply of components is required to maintain a reasonable level of Overall Equipment Effectiveness (OEE) – an important metric that evaluates the effectiveness of the manufacturing operation. Having adequate labor to supply the automated welding system with parts is also imperative. Every moment that a robot sits idle waiting for a part to weld ultimately adds up to lost productivity and increased costs. Automated welding systems require supervision and maintenance. In the process of determining whether this conversion is right for you, you should also assess your available resources and their skill set. Skilled welding operators and/or employees with prior robotic welding experience are the best candidates to supervise the weld cell. If you do not have personnel with those skill sets, be certain that you evaluate the resources (both time and fiscal) you have for training. In many cases, robotic integrators and OEMs offer training that can help provide the necessary troubleshooting and operating skills to manage an automated welding system properly. Once you assess your operation and determine that an automated welding system is a good fit, the next step is find an appropriate robotic integrator (and/or distributor) to make your vision become a reality. In addition to confirming that your parts are suitable and identifying any potential bottlenecks, these individuals can assess your facility to be certain that you have the space and services to support an automated welding system. They can also provide you with advice on updates or tooling changes that need to occur prior to implementation. Likewise, a robotic integrator can help you select the right power source, robot (aka “manipulator”), robotic controller and other key equipment. For example, the ideal power source will be one that helps maximize travel speeds, provides good arc characteristics and minimizes spatter. Additionally, a robotic integrator can discuss the benefits of adding robotic peripherals, such as nozzle cleaning stations, wire cutters and anti-spatter sprayers that focus on extending the life of your welding gun and consumables. Ultimately, the goal when deciding whether to automate your welding operation is to have a thoroughly defined plan before you start. By carefully assessing each aspect of your current welding operation and working with a trusted partner, you should be able to garner all the information you need to make an informed decision and achieve your vision for a more efficient and profitable operation.

When you invest in automation, the goal is to gain productivity and quality improvements that set your welding operation apart from the competition and help increase your bottom line. To achieve success with an automated welding system, however, you need to ensure that the parts you are welding are consistent and repeatable, confirm that your welding operation has good workflow and have properly trained welding operators to oversee the system. You also need the right equipment for the job. In addition to working with a reliable robotic integrator to select and implement the robot, you should also take care to select the right robotic MIG gun and consumables — contact tips, nozzles, liners and retaining heads — for the application. The consumables, in particular, are an easily overlooked part of an automated welding system, but they can have a measurable impact on downtime and day-to-day costs. Consider these suggestions for getting the best performance from these components. The contact-tip-to-nozzle relationship for an automated welding system varies according to the application, but it still has an impact on the welding performance and quality you achieve. Applications that have complex joints or tooling often require an extended contact-tip-to-nozzle relationship. This relationship provides greater access into more complex joints and can help you better accommodate for complex tooling. You should be mindful that this relationship also makes your contact tip more prone to spatter accumulation and may reduce the tip life due to it being more exposed to the heat of the arc. The application of an anti-spatter compound can offer some protection against such situations, but you will also need to monitor your contact tips regularly for signs of wear. Remember, preventive maintenance is better than downtime for resolving problems. Change over your contact tips before issues occur. Using heavy duty copper contact tips is a good option for reliable performance in many welding applications. Contact tips with a hardened insert are ideal for operations employing pulsed welding, as they resist wear from the harsh waveforms, and last 10 times longer than copper or chrome zirconium tips. Checking your contact tips, retaining heads (or diffusers) and nozzles for good connections can also have a measurable impact on your welding performance. Solid connections help ensure reliable electrical conductivity and minimize heat, which in turn provides more consistent weld quality and helps your consumables last longer. Look for contact tips with a long tail and coarse threads, as these help prevent cross-threading and downtime for troubleshooting associated issues like poor penetration. This design aligns the contact tip tail concentrically within the diffuser before the threads engage, making the contact tips easier for less experienced welders to install correctly. These same style contact tips also include greater mass at the front of the tip and bury the tip further in the diffuser than other styles. Such features help the contact tip last longer by resisting wear from the heat of the arc. Longer lasting contact tips mean less downtime for changeover and less risk of installation errors. Also, consumables with tapered mating surfaces provide good electrical conductivity to extend the life of the products. The welding wires you use can impact the performance of your contact tips and it can also affect what size you should use. Larger drums of wires — 500 to 1,000 pounds — are commonly used for automated welding systems to minimize changeover; however, the wire in these drums tends to have less of a cast and/or helix than wire that feeds off of a smaller spool. As a result, the wire often feeds through the contact tip relatively straight, making little or no contact with it. The effect is twofold: one, it minimizes the electrical conductivity necessary to create a good arc and a sound weld; and two, it can cause the welding wire to contact the part being welded and arc back into the contact tip, thereby creating a burnback. This condition automatically creates downtime to change over the contact tip. As a solution, consider undersizing your contact tips particularly if you are using a solid wire. For example, a .040-inch (1 mm) diameter contact tip could work for a .045-inch wire. Check with a trusted robotic integrator or welding distributor if you are using metal-cored wires, as undersizing them is not always feasible due to their tubular construction. You should also consider the impact that the wire you are using has on the longevity of your contact tip. For example, non-copper-coated solid wires tend to wear contact tips (and liners) more quickly than copper-coated ones. The copper on a copper-coated wire acts like a lubricant to improve feedability and can often extend consumable life. It may be worthwhile to factor in the higher up-front cost of these wires compared to the increased cost of purchasing more contact tips for use with a non-copper-coated wire, as well as the downtime for changeover. Automated welding systems require consumables that are capable of withstanding longer periods of welding — and most often higher amperages — than a semi-automatic application. The specific mode of transfer for (GMAW) or (MIG) welding you use can also impact the type of consumables you require. For example, pulsed welding programs in which the power source “pulses” between low background currents and high peaks, are especially harsh on consumables due to the higher levels of heat that the process generates. They tend to cause the contact tip to erode more quickly and therefore require more frequent changeover. You should carefully monitor your contact tip usage if using such a welding program so that you can determine how often the contact tips need to be replaced. Changing over these consumables before they experience problems can help prevent issues like loss of electrical conductivity, burnbacks or excessive spatter accumulation, the latter of which tends to occur when the contact tip becomes too hot and the consumable material softens. Use the time during routine pauses in production for contact tip changeover to avoid interrupting arc-on time. Typically, the tooling on your automated welding system dictates the type of nozzle that you will need to use. Bottleneck, straight or tapered nozzles are common choices since they are narrower than standard nozzles and can provide better access around tooling or into complex joints. Still, always consider the duty cycle and amperage of your application when deciding which nozzle to use. The more tapered a nozzle, typically the thinner it is and the less able it is to withstand higher amperage or higher-duty-cycle applications. If your automated welding system welds at higher amperages (300 amps or greater) and has high levels of arc-on time, it may be a good idea to select a heavy-duty style since these have thicker walls and insulators and are more able to resist heat. Nozzles composed of copper are also a good option, as are those featuring high-temperature fiberglass insulators. Work with your robotic integrator or welding distributor to make the right nozzle selection. Remember that you need to be sure to select one that provides access to the joint, but that is not so narrow (especially in relation to the contact tip) that you compromise shielding gas coverage or unnecessarily shorten the consumables’ life. For all styles and types of nozzles, it is always recommended that you employ a nozzle cleaning station or reamer to help maintain them. A nozzle cleaning station cleans the robotic gun and nozzle of spatter and clears away debris in the retaining head that accumulates during the welding process. These stations can also be outfitted with a sprayer that applies a water- or oil-based anti-spatter compound to protect the nozzle, retaining head, and workpiece from spatter after it has been cleaned. The nozzle cleaning station should be placed close to your robot so it is easily accessible. Also, you should program your robot to use it in between cycles — during part loading or tool transfer — so as not to interrupt your welding operation. It should only take a few seconds for the nozzle cleaning station to complete its job. As a general rule, it is best to select consumables that are well-machined and have smooth, round surfaces, as these are less prone to collecting spatter and tend to last longer. It is also important that you use the heaviest-duty consumables for your application that will still allow you access to tooling. Doing so can help extend their life. Keep in mind that you also need to pay attention to your retaining head selection and the liners that you use in your robotic MIG gun. The retaining head should match your nozzle and contact tip appropriately and offer a secure connection so that you obtain the best conductivity. Also, always trim and install liners according to the manufacturer’s recommendation, using a liner gauge to determine the appropriate length. A liner that is too short or too long can cause wire-feeding problems that require downtime to rectify. As with any part of an automated welding system, the goal is to keep your consumables in working order so that you spend more time reaping the benefits of the process and less time troubleshooting problems.

Most people understand that the electrical circuit is at the heart of the welding operation. What you might not be aware of, however, is how easy it is for disruptions in this circuit to interfere with productivity, weld quality and equipment service life. All of these factors are ultimately affected by conductivity: the ability of the electrical current to flow along the welding circuit. Conductivity can also be referred to through its inverse: resistance, or the interference of electricity to flow freely along the circuit. If the electrical current moves with very little resistance, the material is very conductive. Gold, for example, is one of the most conductive materials on earth (which is why it was used in early telephones and other electrical equipment), but its cost prevents its use in welding equipment. Copper, aluminum and other metals are used in welding equipment because they strike a good balance between cost and conductivity. The copper used in welding equipment does a good job allowing the electrical current to flow. There is still a very small amount of resistance inherent in the properties of the material, but it is not enough to interfere with the welding operation. Excessive resistance along the circuit, however, can cause weld defects, reduce productivity and lead to premature equipment failure. To understand exactly how conductivity impacts almost every aspect of your welding operation, it helps to think about the welding circuit like a garden hose. The water flowing through the hose is analogous to the electrical current in the circuit. If you squeeze the hose in one spot, it reduces the amount of water that is able to flow from the hose. Likewise, an area of electrical resistance, such as a worn out or dirty power pin connection, restricts electrical flow along the entire length of the circuit When resistance prevents the electrons from continuing along the circuit, they convert their energy to heat, which is absorbed by the surrounding components. Heat causes plastic and metal components to expand and to contract when cooled, creating mechanical stress that can lead to premature equipment failure. Interestingly, heat itself is a source of resistance, which is why high heat welding processes, such as with metal-cored wire, demand that the contact tip be recessed as far from the welding arc as practicable. As the contact tip absorbs the heat from the arc, it loses its ability to transfer the current to the wire, resulting in increasingly poor welding performance. Excessive resistance anywhere along the circuit can result in a wide range of problems, including a sputtering or erratic arc, inconsistent weld appearance and frequent contact tip burn-back. These problems occur because resistance in the circuit reduces the amount of current that can flow to the welding arc. When the power source senses the reduced current at the arc, it sends a surge of voltage in order to overcome the restricted current flow. This increased voltage causes the popping and sputtering that leads to poor and inconsistent weld quality. Being able to correctly identify and troubleshoot excessive electrical resistance is critical to reducing the equipment and rework costs. The mechanical connections between the welding components account for most interruptions in conductivity. These include: the connection between the power source and the gun’s power cable plug; the fittings and connections between the gun’s power cable, neck, diffuser, contact tip and welding wire; and the connections between the work lead, welding table and power source. Routinely check these connections before problems arise in order to avoid compounded problems down the road. There are three main types of power cable terminations: compression, set screw and crimped. Compression fittings typically provide the best combination of durability and reparability. Set screw fittings are easily repaired, but often come loose and require frequent tightening. Crimped fittings provide good contact between the cable and gun, but are also susceptible to overheating and gradual degradation. Loose cable, gun and power source connections should be tightened to manufacturer specifications or replaced if damaged. Because the welding wire wears the bore over time, the contact tip should be one of the first areas checked during troubleshooting. A contact tip that doesn’t maintain constant connection to the welding wire should be replaced, regardless of whether it is the primary source of the conductivity problem. Paint and other surface contaminants can reduce the conductivity of the work lead connection. To ensure maximum electrical flow, attach the work lead clamp to clean, unpainted metal and as close to the weld joint as possible. If using rotating work leads, such as turntables and positioners, conductive grease can help increase the conductive surface area between the moving and non-moving parts. The other most frequent source of interruptions in conductivity is frayed copper stranding within the gun or, less frequently, in the work lead cables. These strands can fray and break due to repeated bending and twisting, particularly on guns that don’t contain strain relief components at the connection points with the gun and power source. Also, thermal stresses can cause the copper stranding to become brittle, increasing the likelihood of fatigue failure. For this reason, the gun cable should only be bent or twisted if absolutely necessary. The resistive heat caused by frayed cable stranding, in addition to causing poor weld performance, can also accelerate the degradation of the remaining intact strands and cause the eventual failure of the cable. Unfortunately, it is difficult and often impractical to inspect the cable for damage as a preventative measure. Check the mechanical connections and fittings first if poor conductivity is the suspected source of a welding problem, and then proceed to check the condition of the cable. It may be possible to cut and re-terminate the cable if the damage occurs near the connections to the power source or gun. Severe cable damage or damage near the middle of the cable may require replacement of the cable or the entire gun. Welding technology has advanced substantially since the days of DC ‘buzz boxes,’ but one thing that has remained constant throughout the decades is the need to establish and maintain a robust electrical circuit. Resistance from loose fittings and connections will occur as a natural part of the wear and tear that welding equipment undergoes during normal use. However, knowing the common signs of poor conductivity and following a regular inspection routine will help ensure that built-up resistance doesn’t cause undue equipment and rework costs.

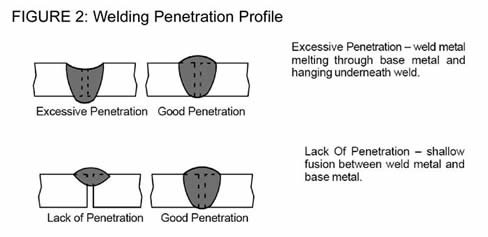

Like any welding process, MIG welding has its complications. Even so, there is no reason to let common problems slow you down. With a bit of knowledge and some solid troubleshooting skills, you can easily find the right solution to get back to welding—sooner than later. Consider the following guidelines to help you along the way. Porosity occurs when a gas pocket becomes caught in the weld metal. This discontinuity can appear at any specific point on the weld or along its full length, and/or on the surface or the inside of a weld. The result, regardless of the location, is always the same: a weaker weld. Inadequate shielding gas coverage is one of the most common causes of porosity. To correct this problem, first check the regulator or flow meter for adequate gas flow, increasing it if necessary, and check the gas hoses and the gun for leaks. Whether welding inside or outside, shield the arc and weld puddle from drafts with a welding screen. Next, confirm that the MIG gun nozzle is large enough for the application, as too small of a nozzle can prevent proper shielding gas flow. Keep the nozzle one-fourth to one-half inch away from the work piece, make certain it is free of spatter, and always use the correct contact tip recess. Slow your travel speed and hold the MIG gun near the bead at the end of the weld until the molten metal solidifies; pulling the gun away too soon can interrupt gas coverage and leave the setting weld vulnerable to the atmosphere. Additional causes of porosity include: using the wrong gas (always use a welding-grade shielding gas appropriate for the base metal and filler metal), using too much or the wrong type of anti-spatter (use the correct amount and type for your application) and extending the welding wire too far out of the nozzle (extend no more than one-half inch beyond the nozzle). Impurities in the base metal, such as sulfur and phosphorous in steel, or a dirty base metal can be further causes of porosity. If specifications allow, consider changing to a different composition of base metal, and always remove rust, grease, paint, coatings, oil, moisture and dirt prior to welding. Filler metals with added deoxidizers can help to “clean” the weld, but should never be solely relied upon to minimize porosity. Finally, replace any wet or contaminated shielding cylinders immediately. Undercutting occurs when a groove melts into the base metal next to the toe of the weld and the weld metal fails to fill that area. This discontinuity weakens the toe of the weld, increasing the chances of cracking. Correcting the problem is relatively simple: reduce the welding current, decrease the welding arc voltage and adjust your MIG gun angle toward the joint. Reduce your travel speed so the weld metal completely fills the melted-out areas of the base metal. When using a weaving technique, pause slightly at each side of the weld bead. When the weld metal fails to completely fuse the weld metal with the base metal or with the preceding weld bead in multi-pass applications, incomplete fusion can occur. Some people refer to this problem as lack of fusion. Generally, an incorrect MIG gun angle is the cause and you should adjust it accordingly. Follow these steps: If correcting the MIG gun angle does not remedy incomplete fusion, look to see if the welding puddle is too far ahead of the wire. If so, increase your travel speed and/or the welding current to correct the problem. Conversely, if you suspect insufficient heat input has caused incomplete fusion, select a higher voltage range and/or adjust the wire feed speed as necessary. Finally, always clean the surface of the base metal prior to welding to remove contaminants that may prevent the metal from fusing together. Another common MIG welding problem—spatter—occurs when the weld puddle expels molten metal and scatters it along the weld bead; this molten metal then cools and forms a solid mass on the workpiece. Excessive spatter not only creates a poor weld appearance, but it can also lead to incomplete fusion in multiple welding pass applications. Too fast of a wire feed speed, too high of a voltage setting, and too long of a welding wire extension, or stick-out, can cause spatter. Lowering the given settings and using a shorter stick-out can help. Like porosity, insufficient shielding gas and/or dirty base materials can cause spatter. As necessary, increase the shielding gas flow at the regulator and minimize drafts near the welding arc, clean and dry the welding wire, and remove all grease, dirt and other contaminants from the base metal. Other factors that can cause spatter are: the wrong size contact tip, a worn contact tip or the wrong tip to nozzle recess. Be certain you have the right contact tips, nozzles and recess parameters for the application. Excessive penetration occurs when the weld metal melts through the base metal and hangs underneath the weld. Excessive heat input is usually to blame for the problem. To correct this, select a lower voltage range, reduce the wire feed speed and increase your travel speed. Conversely, insufficient heat input can cause lack of penetration, or the shallow fusion between the weld metal and the base metal. Selecting higher wire feed speed, a higher voltage range and/or reducing travel speed are all viable remedies. Preparing the joint correctly also helps prevent lack of penetration—the preparation and design should permit access to the bottom of the groove and allow you to maintain proper stick-out and arc characteristics. Wire feed stoppages and wire feed system malfunctions can adversely affect the welding arc and create irregularities that may weaken the weld bead. Birdnesting, a tangle of wire that halts the wire from being fed, is a common problem. You can resolve birdnesting by flipping up the drive roll and pulling the wire back out of the gun. Next, trim the affected wire and re-thread it through the feeder and back to the gun. If the welding specifications allow, decrease the drive roll tension, use a larger diameter wire and/or reduce the distance the wire feeds (use shorter cables) to minimize the chance of birdnesting. Burnback is also very common. It results when a weld forms in the contact tip, and usually occurs because of too slow of wire feed speeds and/or from holding the MIG gun too close to the base metal during welding. To correct burnback, increase the wire feed speed and lengthen the distance of the MIG gun from the workpiece (the nozzle should be no further than one-half inch from the metal). Replace burnback-damaged contact tips by removing the nozzle and the contact tip (which may be melted to the wire), snipping the wire, installing the new contact tip and replacing the nozzle with one that has the appropriate tip recess for the application. Other causes of wire feeding problems include liner blockages, improperly trimmed liners (too short/burred/pinched) or the wrong size liner. To remedy these problems, replace any liner if you find a blockage, always trim the liner according to the manufacturer’s direction and be certain you are using the correct size liner for the welding wire diameter. Remember, quality MIG welds are the result of not only good welding technique, but also your ability to identify and solve problems quickly if they do occur. Continue arming yourself with some basic information and you’ll be able to tackle the most common problems associated with MIG welding without sacrificing time or quality.

There are regular job shops. Then there are job shops that go far beyond basic fabrication — ones that design, machine, laser cut, manufacturer and inspect specialty components from start to finish. Watson Engineering, Inc. of Taylor, Mich. is just such a one. What began as a one-person fabrication shop nearly thirty years ago is now a full-service manufacturer of prototype tubular and sheet metal components, along with products for the automotive and commercial industries. And whether its welding operators are retrofitting race cars with roll cages or manufacturing high-volume runs of heavy equipment components, Watson prides itself on one simple philosophy set forth by founder, Chuck Watson: “Customers come to Watson Engineering with problems they need help with – and we make the problems go away.” The company has been able to achieve this goal through a lot of hard work and even greater innovation. Not to mention, this job shop is lean. Every tool, every bin and every piece of welding equipment has its place — and that place has been chosen for maximum efficiency. In fact, the entire organization of Watson’s facility has been the result of all of its employees’ commitment to the company’s lean initiatives, from concept to painting and shipping. Not surprisingly, as part of its ongoing innovation and its lean initiatives, Watson decided to look as closely at its robotic welding cells, too. In doing so, they decided to convert to Tregaskiss’ TOUGH GUN I.C.E.® robotic MIG gun in order to solve a long-standing problem: finding a durable gun that could maintain its accuracy after a collision. They also added several of Tregaskiss’ air-cooled TOUGH GUN robotic MIG guns to other welding cells. After adding the products, they were surprised to find a few extra benefits that directly support their lean initiatives and have also contributed to a 25 percent increase in Watson’s overall productivity. Watson prides itself on the ability to produce components that have exceptionally intricate or complex designs. Not surprisingly, such designs can pose some particular challenges to the welding process, especially when the components are comprised of a wide range of materials and material thicknesses. According to Rafael Velasquez, robotic supervisor at Watson, in any given day the company may weld exhaust manifolds for an automotive customer, hood hinges for a commercial customer and thousand pound internal components for a heavy equipment manufacturer — sometimes in the same work shift and the same robotic welding cell. Not to mention, all the products undergo rigorous quality control testing (Watson even performs 100 percent lot tests on some parts), so quality is key and downtime is simply not an option if they are to create top notch products on a tight schedule. One of the biggest obstacles that Velasquez and his fellow Watson welding operators have faced over the years is finding a robotic MIG gun that could “take a hit without bending the neck” after a collision. Despite the best precautions, robotic welding collisions are a very real problem, resulting most often from tooling clamps not being secured. If the robotic MIG gun neck bends, it must be adjusted or replaced since the robot’s tool center point (TCP) will change and have a negative impact on the quality of subsequent welds. “We’re always changing parts and tooling,” explains Velasquez. “Unfortunately, you can bend two or three necks in a week because of it. Somebody would miss a clamp and leave it up. It happens.” After enough bent necks, downtime and just plain frustration, Velasquez opted to contact Watson’s long-time distributor, Dan Gnesda of Roy Smith Company in Detroit for help. Gnesda recommended the TOUGH GUN I.C.E. Robotic MIG Gun and the results, per Velasquez, have been worthwhile. Prior to converting to the TOUGH GUN I.C.E. robotic MIG gun, Watson used a competitive brand water-cooled gun, which Velasquez explains was quite costly and time-consuming to fix after a collision. Fundamentally, necks for water-cooled robotic MIG guns tend to be weaker than air-cooled designs and involve more work to replace, in major part because the water lines run internally through the power cable, gun and neck. To replace the water-cooled neck after a collision, Velasquez and his team needed to disconnect the neck from the gun and unhook the water lines by removing clamps that were crimped around them — a process that took about 30 minutes. Converting to the TOUGH GUN I.C.E. robotic MIG gun, however, seems to have offered Watson the best of both worlds: the durability of an air-cooled MIG gun and the cooling capacity of a water-cooled gun. I.C.E stands for ‘Integrated Cooling Enhancer’ and aptly describes the design of the gun, as it is a ‘hybrid’ between conventional air- and water-cooled designs. The TOUGH GUN I.C.E. robotic MIG gun features stainless steel water lines that run along the outside of the gun’s neck down to the nozzle, rather than through the neck like true water-cooled products. This design provides water circulation that keeps the consumables of the gun running cool, but because the lines are external (instead of running through the neck), the gun’s neck has more mass and is stronger, much like that on an air-cooled gun. According to Velasquez, the necks on the TOUGH GUN I.C.E. robotic MIG guns “can take the hit” most times after a collision, and in the event that the neck does bend, it can be replaced in about five minutes — a timeframe that fits nicely into Watson’s overall lean initiatives. The TOUGH GUN I.C.E. robotic MIG gun also features water shut-off valves at the I.C.E. connections and a quick-change neck feature. To disconnect the neck, Velasquez simply loosens a setscrew on the gun housing, disconnects the quick-change fittings for the water lines and slides on a new neck. After reconnecting the water lines and verifying his TCP, he can get the welding operation up and running again. “My emergency calls from Watson used to come through every other week with the previous gun, because of the crashes,” explains Gnesda. “After replacing the necks, there could be leaking or something else that was off. Now with the TOUGH I.C.E. gun, well, I hear from them every couple of months.” And because, the TOUGH GUN I.C.E. robotic MIG gun provides up to 550-amp capacity (at 60 percent duty cycle with mixed gases), it provides Watson with another solution that fits their goals for creating a lean facility: it can weld on a variety of material thicknesses. There is no need to change out robotic MIG guns to accommodate for the ever-changing flow of components that make their way through the weld cell each day — a factor that saves Watson money and time. “We have a lot of high amperage, high voltage welds. And we weld on thinner metals, too,” explains Velasquez. “Some of our components are thirty-millimeters thick and others are as thin as three mils. I can weld both. I just have to change out the wire.” As with the durability of the gun’s neck and the occasional changeover, being able to use the same gun for all its parts has contributed significantly to Watson’s lean initiatives. “There’s so much going on here with all the parts they weld, it’d be very easy for things to get out of control.” says Gnesda, “But these guys have a handle on everything. I think the I.C.E. is helping with that.” The goal of Watson’s lean initiatives has been to improve workflow, minimize downtime and, of course, improve productivity and profitability. After converting to the TOUGH GUN I.C.E. Robotic MIG Gun, and also adding several Tregaskiss® TOUGH GUN® robotic MIG guns to their other welding cells, Watson found that their equipment maintenance also became easier and they reduce their inventory, too — both benefits they had not anticipated. Velasquez first noticed that the total cost of maintaining the TOUGH GUN I.C.E. robotic MIG gun was substantially lower compared to the conventional water-cooled MIG gun Watson used previously. In addition to the fact that the necks have been more durable and easier to replace when needed, he found that the gun’s unicable has been equally robust. In fact, according to Velasquez, he only just recently changed out the original unicable that came with the TOUGH GUN I.C.E. robotic MIG gun two and a half years ago. “We’ve been running around the clock, six days a week each year with the same one,” he explains. “To change it, I just loosened a couple of screws, popped it out and put on the new one. With the addition of a new liner, I just connected the unicable back at the feeder. It took me fifteen minutes and we’re done.” Saving the cost of purchasing unicables on a regular basis has been a welcome benefit for Watson, as has its reduction in inventory for this and other MIG gun parts. Since Velasquez began using the TOUGH GUN I.C.E. robotic MIG gun and the air-cooled TOUGH GUN MIG guns for his other welding cells, he has also been able to reduce his inventory for necks significantly, too, as many are interchangeable. “I used to have so many necks in stock, sometimes about fifteen different ones. Now I’ve got three necks I can use on all the robots. I don’t have to have so much inventory to keep this place running,” says Velasquez. He’s also been able to reduce his consumables inventory. Both the TOUGH GUN I.C.E. Robotic MIG Guns and the standard TOUGH GUN MIG Guns operate on Tregaskiss’ Common Consumable Platform, meaning that the front-end consumables — nozzles, contact tips, retaining heads and liners — are the same for both guns. Velasquez explains that he uses standard and heavy-duty TOUGH LOCK® consumables for all the guns, depending on the thickness of the parts his robots are welding and at what amperage. He simply orders the parts that correspond to the different wires he uses between part runs. Velasquez also explained that when he changes over the contact tips on his robotic MIG guns, he then uses them for the semi-automatic MIG guns Watson uses in other portions of the facility. So what’s the bottom line of these and all the other benefits Watson has found with its lean initiatives? According to Velasquez, Watson’s lean initiatives — including the benefits brought forth from the TOUGH GUN I.C.E. robotic MIG guns and other Tregaskiss products — have combined to provide a 25 percent increase in the company’s productivity. The process is ongoing, of course, but it’s been made easier by the commitment of Watson’s employees who have all played a significant role in organizing the facility, from the concept phase of the many components it manufactures to the machining, storing and assembly of the parts. Having a durable, easy-to-maintain robotic MIG gun and minimizing Watson’s inventory has definitely helped improve workflow and reduce downtime, too. “We’re serious about lean,” says Velasquez. “We try to complete jobs from concept to finish within days. The I.C.E. and other Tregaskiss products have definitely helped us.”

The economy is in bad shape right now, but when it improves, the graduates of San Diego Continuing Education’s welding program will be well positioned to fulfill the need for skilled welders. Now in its 35th year, the school focuses on adult education for unemployed and underemployed San Diego-area residents. Its curriculum is narrowly tailored to the needs of local industries — specifically shipbuilding, construction and manufacturing. The school provides free training to any California resident and currently has 96 students and a waiting list of an additional 58 people. “Our program is set up to provide the student with experience on the same types of joint configurations, metal types and welding processes that they’re going to need when they enter the workforce,” explains welding instructor Bill Borinski. The program, which spans a minimum of 600 hours over 24 weeks, also prepares the students with the skills to obtain an AWS D1.1 (American Welding Society) Unlimited Certification by passing a visual and x-ray weld evaluation. Even with the school’s focused, industry-driven curriculum, there is still a vast amount of knowledge and skills to impart to the students, and the school strives to make every minute count. That, explains Borinski, is why it is so important for the school to have durable, time-saving welding equipment. “Downtime in business costs money — for us it costs knowledge,” he says. “If a student’s equipment is down, then he’s not learning. Our students have enough to concentrate on as it is, they shouldn’t have to worry about whether their equipment is working properly or not.” The school recently converted its welding labs to Bernard™ Q-Gun™ and Dura-Flux™ MIG Guns and Centerfire™ Consumables to prevent such problems. The guns and consumables came packaged with the school’s new power sources and wire feeders, and Borinski said he’s been very satisfied with the results. The program has been running the guns for 12 hours a day, four days a week, and there hasn’t been a single malfunction. The Centerfire consumables system has reduced student downtime and frustration, while also improving weld quality. In this open-enrollment program, students work on the material at their own pace until they master the skills required to graduate. New classes, which meet for 6.25 hours a day, four days a week, begin every month, and students can stop and start the program at their discretion. Students learn an AWS-certified curriculum in self-shielded and gas-shielded flux-cored welding on 3/8- to 1-inch mild steel using E70T-1 and E71T-8 welding wire. Students briefly learn the GMAW process, but the program spends the majority of its time providing specific skills that are needed immediately in local industries. They focus on building proficiency in all welding positions on butt, corner and T-joints. The school uses Bernard Q-Gun MIG Guns for its gas-shielded flux-cored and MIG training. Borinski noted that the gun’s curved handle reduces his students’ muscle fatigue after welding for long periods of time, and that the guns also improve their mechanical leverage, making it easier for the students to hold the guns in flat and horizontal welding positions. “What my students and I love about the Q-Gun handle is that when you put it in your hand, it’s already in a position to weld,” Borinski said. “If the MIG gun is putting strain on my students’ wrists, they’re going to be sore and miserable by the end of the day and they’ll probably lose some of their enthusiasm for a career in welding.” The Centerfire system further reduces his students’ educational downtime and frustration levels, Borinski said. By using a threadless contact tip with a large diameter tapered base that fits snugly into the diffuser and is locked in place by the nozzle, the Centerfire consumables make it nearly impossible for students to set incorrect contact tip recesses or for the tip to come loose inside the nozzle. “With our old brand of consumables, if we didn’t screw the contact tips in properly they would come loose and literally fly out of the end of the gun. That can really add to the frustration of a beginning welder,” Borinski said. While he is pleased with the guns and consumables, Borinski noted that it’s Bernard’s customer service that will keep him as a customer when their equipment eventually needs to be replaced. “To us, a gun is a gun,” Borinski said. “We can figure out on our own how it operates. Still, we were really impressed when a Bernard representative came out and offered to exchange any of our guns for free if the stock model didn’t perfectly fit our lab set ups.” Bernard’s Gun Exchange Program allows any one who receives a standard Q-Gun or Dura-Flux MIG Gun as part of a power source or wire feeder package to exchange the unused gun for a new gun with different cable length, neck, handle or trigger configurations. Bernard also provided Borinski with product information and support prior to and following his purchase to ensure the guns and consumables he ordered would meet his needs. “Sometimes the educational community gets sheltered from a lot of the outside activities that are going on. We don’t get exposure to the different equipment options that are out there,” Borinski said. “When Heidi Ewoldt, Bernard’s Inside Technical Sales Manager, called us and spent time explaining all of the equipment options and configurations available, it told us that Bernard wanted more than a quick sale. They were committed to our success.” “We’re running some pretty hot, high-amperage applications here,” Borinski said, “and we have had zero failures — zero internal issues, zero electrical issues. We haven’t even needed to change the liners on some of the guns.” Like Bernard, San Diego Continuing Education understands the value of strong partnerships and adapting its products to its customers’ needs. In order to meet the evolving demands of area industries, Borinski meets annually with an advisory committee composed of business and union leaders to discuss the skills and knowledge they look for in new employees. “If we taught what we wanted to teach and not what the employers in the area need, then we’re sending them people they can’t use and wasting our students’ time,” Borinski continued. “We must have our pulse on the industry in order to be a relevant educational institution.” In the last few years, Borinski said, the advisory committee has been asking for employees with “soft skills,” such as blueprint reading, teamwork training, lean manufacturing processes and other skills that go beyond laying a weld bead. “The job market is very competitive now,” Borinski said, “and those students with additional skills, who can add value to the organization, are going to have a significant advantage during the interview process.” That’s why the school partnered with the AWS to form a curriculum that provides students with the knowledge and skills they need to become AWS Certified Unlimited in FCAW upon graduation. The unlimited designation is a guarantee that the student can perform code-quality welds in the 1-G, 2-G, 3-G and 4-G positions using the FCAW process. This certification, combined with the schools blue print reading and teamwork curriculum, gives graduates a strong advantage when applying to one of the area unions, Borinski said. The school’s approach to welder training has resulted in numerous opportunities for its graduates in area businesses. One example is the school’s partnership with General Dynamics NASSCO, one of the San Diego’s largest employers. Through the partnership, General Dynamics NASSCO has hired over 400 of the program’s graduates in recent years. The main reason San Diego Continuing Education tried the Bernard guns and consumables was that they came packaged with the wire feeders and power sources the school purchased. Still, after using them without a single failure for the last 18 months, Borinski said one of the first questions he will ask when purchasing new equipment will be whether they accept Bernard guns and consumables. Luckily for him, Bernard’s products are adaptable to almost all major power source and wire feeder brands.

For some companies, choosing between an air-cooled or a water-cooled MIG welding system is pretty cut and dry. Mobile fabrication and repair companies that weld sheet metal for only a few minutes every hour will have little need for the benefits provided by a water-cooled system. Likewise, shops with stationary equipment that repeatedly weld at 800 amps probably won’t be able to find an air-cooled system that can handle the heat of the application. But for many companies, however, it’s not such an easy decision. Each type of cooling system has advantages and disadvantages, and deciding which is right for your company requires a careful analysis of the following factors: Keeping MIG welding equipment cool is necessary to protect the power cable, gun and consumables from damage due to the radiant heat from the arc and the resistive heat from the electrical components in the welding circuit. It also protects the operator from heat-related injuries and provides more comfortable working conditions. A water-cooled MIG welding system pumps a cooling solution from a radiator unit, usually integrated inside or near the power source, through cooling hoses inside the power cable and into the gun handle, neck and consumables. The coolant returns to the radiator where the radiator’s baffling system releases the heat absorbed by the coolant. The ambient air and shielding gas further disperses the heat from the welding arc. An air-cooled MIG welding system relies solely on the ambient air and shielding gas to dissipate heat that builds up along the length of the welding circuit. Air-cooled systems use much thicker copper cabling than water-cooled systems, which allows the cable to transfer the electricity to the gun without building up excessive heat from electrical resistance. By contrast, water-cooled systems use relatively little copper in their power cables because the cooling solution carries away the resistive heat before it builds up and damages the equipment. The welding amperage will be an important factor to weigh when deciding between an air- or water-cooled system. In general, air-cooled systems are better for low amperages and water-cooled systems are better for high-amperage applications. Air-cooled guns are available with ratings from 150 – 600 amps, and water-cooled guns range from 300 – 600 amps. These ratings represent the current loads under which the guns become so warm that they are uncomfortable for the average operator to hold. Because guns are rarely used to the limits of their duty cycle, it’s often a good idea to purchase a gun that’s rated to a lower amperage than the maximum to which it will be exposed. For example, a 300-amp gun can handle more than 400 amps and it is substantially lighter and more maneuverable than a 400-amp gun. Closely related to a gun’s amperage capacity is its duty cycle — the amount of time during a 10-minute cycle that the gun can operate at its rated capacity without becoming uncomfortably hot. Exceeding a gun’s duty cycle can lead to operator pain and will also reduce weld quality and decrease the service life of the gun and consumables. There is no industry standard for establishing amperage ratings based on duty cycle, so two guns both rated to 400 amps could have significantly different duty cycles. This makes it important for the customer to consider a gun’s amperage rating and duty cycle together in order to form an accurate assessment of the MIG gun’s capabilities. Welding all day long in an industrial or construction environment can take a significant toll on the hands, arms, shoulders and back (not to mention most other body parts) of a welding operator. A heavy, bulky and difficult-to-maneuver gun only exacerbates these aches and pains, and it accelerates the time they take to set in. One of the benefits of water-cooled guns is their size and weight. Because water is more efficient than air at carrying away heat that builds up from the heat of the arc and electrical resistance, water-cooled guns use less wire for their cables and smaller gun components, resulting in reduced operator fatigue. Although air-cooled guns are generally heavier and more difficult to maneuver than water-cooled guns, significant differences in gun design between manufacturers can also have a big impact on how quickly the gun contributes to fatigue. It’s a good idea to physically hold a gun to determine its comfort level prior to making a purchase. Because water-cooled guns require more equipment than air-cooled systems, they can be impractical for applications that require portability. Transporting the cooling system and coolant hoses of a water-cooled MIG gun can reduce productivity and cause unnecessary downtime. Water-cooled systems are most practical in applications where they will be stationary or moved very little. By contrast, air-cooled MIG guns are easily carried and moved from site to site within a shop or out in the field. Finally, companies must evaluate the cost of the two systems before making a purchasing decision. Doing so, however, is not as simple as looking at their respective price tags. In addition to the sticker price of the systems, companies need to consider maintenance costs as well as productivity and downtime costs associated with operator fatigue and equipment longevity. A water-cooled system requires the purchase of a coolant flow system (including radiator, pump, hose lines, etc.), which leads to a higher up-front cost than an air-cooled system. Because water-cooled systems require a special coolant solution in order to avoid mineral or algae build-up in the coolant lines and radiator, they involve more extensive maintenance and higher operational costs than an air-cooled system. Furthermore, coolant leaks can lead to equipment damage and weld discontinuities that add to the cost of owning a water-cooled system. In addition to being less expensive up-front, an air-cooled system also offers the advantage of being better suited to low amperage applications. Thus, for example, a company that needs to weld at 150 amps and 600 amps in the same weld cell can keep its costs down by purchasing a single air-cooled system rather than a water-cooled system for the high-amperage applications and an air-cooled system for the low-amperage applications. That doesn’t mean, however, that a water-cooled system is more expensive than an air-cooled system. As mentioned earlier, a water-cooled MIG gun is much smaller and more lightweight than an air-cooled MIG gun, which can help decrease operator fatigue and increase productivity over the course of a day. When set up properly, a water-cooled MIG gun can provide significant long-term cost savings compared to an air-cooled gun. The coolant in a water-cooled system also extends the service life of the consumables by drawing away the heat absorbed from the arc. Longer consumable life means less downtime for changeovers and lower consumables inventory. Unfortunately, there is no one-size-fits-all formula for choosing between an air-cooled and a water-cooled MIG welding system. Each company must analyze their welding operations and determine which type of system offers the benefits most important to them. Considering these factors — cost, worksite location, gun weight and operator comfort, duty cycle and amperage requirements — will provide a good start toward making a wise decision. Find an air– or water-cooled MIG Gun for Your Application

Worldwide, companies serving the automotive industry have faced a unique set of challenges in the last several years. Still, as the economy begins to rebound, each must find ways to maintain their productivity and profitability — often with fewer employees than before the recent recession. A large part of maintaining that productivity is to ensure high levels of uptime in the robotic welding operations. Conventional problems like spatter, burn-through and poor part fit-up often hinder such attempts, as do issues like managing large amounts of inventory and contending with downtime to service welding equipment. Unfortunately, there is no single answer to these challenges. There are, however, some considerations that may help reduce suppliers’ pains and assist in other interrelated parts of the process. The recent increase in demand for production is causing some automotive suppliers, especially those in North America, to make capital investments that they previously postponed during the recession. When possible, standardizing on a single brand and style of welding power source, robotic controller, and GMAW gun and consumables during this investment can streamline inventory and maintenance procedures. For companies in organic growth mode with new programs and/or Greenfield operations, this standardization can help in long-term equipment re-deployment to other facilities, as well as streamline the manpower learning requirements. For companies that are in acquisition mode, however, this standardization may not be feasible. Instead, these suppliers should, at a minimum, consider standardizing on a single brand and style of robotic GMAW guns and consumables to minimize inventory. Doing so can also reduce the risk of improper consumable installation, which can lead to unscheduled downtime to rectify. Many automotive suppliers rely on tandem welding processes as a means to generate greater productivity. In recent years, however, advancements in single arc pulsed technology have proven very efficient in providing faster travel speeds and minimizing spatter. This technology, which effectively lowers the average amperage level during welding (by regularly switching the current between high peak amperages and low background amperages), is also quite easy to operate. Given the reduction in workforce in the automotive industry, combined with an overall shortage of skilled welders, this less complex (but highly efficient) technology has already proven beneficial for many automotive suppliers. Automotive suppliers, particularly those with multiple locations, may want to consider purchasing their robotic GMAW guns, peripherals and consumables from a single source vendor or welding distributor. Having multiple vendors may appear to provide cost savings up front; however, a per-item approach can actually increase the total spend. Instead, by single sourcing a product line, a company is better poised to maximize their purchasing power with one vendor and gain loyalty discounts. The vendor may also be more inclined to aid in new efficiencies and technologies. Plus, a trusted single source vendor can often help automotive suppliers assess their total consumable and robotic GMAW gun usage, streamline inventory and reduce costly paperwork at the same time. In addition to standardizing equipment when possible, using welding products that minimize the opportunity for errors is an important part of keeping the welding process flowing and reducing operator error. For example, nozzle detection (i.e. that doesn’t increase cycle time) can eliminate the potential of excessive rework or scrap. Avoiding errors in equipment installation is also critical, as missing or incorrectly installed components on the front end of a robotic MIG gun can cause them to become electrically alive, causing premature failure and poor welding performance. When possible, suppliers in the automotive industry should work with equipment manufacturers and vendors or welding distributors who can engage regularly in best practice meetings. These meetings can occur by conference call or in person, and can help determine what practices in the welding operation are working most effectively and what areas need improvement. Open issues can be prioritized amongst a group for time-phased solutions. These meetings can especially help companies with multiple locations, even globally, to identify opportunities for changes that could positively affect other facilities. They are also an excellent platform for brainstorming error-proofing ideas and serve to open communication among the parties involved in the success of a company’s welding operation. Even though preventive maintenance or PM may have become a commonplace buzzword in recent years, the fundamentals are still critical to providing good welding performance and reducing unscheduled downtime in the automotive industry. Companies should always take care to inspect connections in the GMAW gun, wire feeder, consumable and ground cables on a regular basis. Replacing worn components during scheduled downtime (at the beginning of a shift, for example) can help prevent problems during production. As of yet, “predictive maintenance” —– technology that alerts when consumables need to be changed – is not available. In the meantime, however, companies can instead track contact tip usage to gain an understanding of how often these components need to be replaced. Non-subjective analytical processes should be used to benchmark component longevity and performance. During Best Practice meetings, “Coopetition” can be an integral part of maintaining an effective welding operation for the greater good of the customer. This term refers, in short, to cooperation that occurs between competitive equipment manufacturers. The reality of any welding operation is that the manufacturer of the robotic GMAW gun or welding wire may be in direct competition with the company whose power sources are in an automotive supplier’s weld cell. Even so, finding equipment manufacturers who are willing to work together to address problems in the welding operation is key to resolving issues when they arise. A problem with the contact tip, for example, is usually a “barometer” of other things happening in the process. In short, it is very often a symptom of a problem, as opposed to the root cause. Having partners who are willing to put aside competitive differences for the good of resolving problems like these is important to gaining good welding performance. As is typical in automotive “just-in-time” applications, suppliers want to reduce instances of work-in-progress (WIP) and keep parts flowing (Takt time). To continue that work flow but still allow for any instances of stoppage in a robotic welding cell, suppliers may consider building a buffer into production. For example, if a company has a production line of 40 welding robots, breaking that line into fifths (five sections of eight robots), allows them to address any instances of consumable failure while causing a stoppage of only eight robots instead of shutting down production on all 40. That buffer can mean a significant difference in terms of lost production and money. And while no single one of these considerations can ensure the levels of productivity and profitability to which automotive suppliers strive as production demands increase, they can be a step in the right direction. Automotive suppliers should consider working with a trusted welding equipment manufacturer and vendor to discuss a plan for assessing their robotic welding operation and identifying opportunities for improvement.

The automotive industry has certainly begun to show signs of rebounding from the economic downturn; however, companies are now being asked to “do more with less” as production volumes approach the levels of several years ago. More than ever, companies require operational efficiencies to maintain process flow and avoid unscheduled downtime of automated equipment. Commonly, arc-welding process challenges have a significant impact on achieving production goals and maintaining efficiency. Typical contributors to arc-welding process inefficiencies include poor part fit-up, tool center point (TCP) repeatability, spatter and managing consumable changes. Effectively managing these elements are essential if companies are to meet their quality requirements and fulfill a high-volume production demand. As the automotive industry continues experience an upswing in production—up 12.16 percent year-over-year through March 19, 2011 (Automotive News)— maintaining an effective and efficient operation will become even more challenging. Reductions in the workforce over the last several years have left the industry with fewer employees to monitor welding operations and the overall shortage of skilled welders has compounded the challenge. Whereas 10 years ago a large automotive supplier may have had one welding technician for 20 robots, today that ratio has increased to as few as one welding technician for every 50 robots – or more. Clearly, the lack of resources creates challenges but eliminating non-value-added activity (or that which doesn’t contribute directly to throughput) can help overcome those. Practices such as equipment standardization, preventive maintenance and product selection can promote a Leaner operation and provide opportunities to improve process flow and operational efficiency. In recent years, the consolidation of automotive suppliers and facilities has resulted in welding operations made up of multiple styles and brands of welding equipment, including power sources, robotic controllers, robotic manipulators and GMAW guns. The outcome is often a wide breadth of products to manage and, with fewer resources, an increased potential for costly errors and unscheduled downtime. Not surprisingly, in an industry that requires repeatable, high-volume welds—some up to 500 parts in a single shift—consistency is critical and any deviation in quality could result in downtime, scrap or rework. Ideally, standardizing on a single GMAW gun brand can help companies in the automotive industry avoid unscheduled downtime for changing out incorrect consumables or reworking quality issues. It can also reduce the amount of time spent managing inventory and provide a built-in poka yoke (mistake-proofing) system by eliminating (or significantly reducing) the opportunities for incorrect installation. Some companies have found that such standardization, along with a vendor-managed consumable system works well and contributes positively to their goal of maintaining process efficiency and equipment utilization. The process of standardization may take time—replacing older GMAW guns as they wear, for example—but in the long term it can yield positive results in quality, performance and cost. It also allows the production team to have one point of contact for technical support should questions arise about the performance of a GMAW gun or consumable, as opposed to having to contact multiple manufacturers. To help with the transition to one GMAW equipment supplier, front-end conversion kits are widely available and allow companies to standardize on a single brand of consumables, regardless of the type of GMAW gun being used. These kits are a good alternative to replacing an entire fleet of GMAW guns, while still offering the benefits of standardized inventory. In some cases, there is an opportunity to maximize the value of welding consumables by using the same contact tips and nozzles for semi-automatic applications (such as those for repairs or rework) after they are too worn for the robotic application, which further reduces inventory. Most welding technicians, supervisors or operators in the automotive industry will attest to the fact that proper part fit-up is a constant concern. But not only do the parts that move into the weld cell need to be of the proper dimension and fit, the GMAW welding gun and consumables being used also need to provide accurate, repeatable and durable performance. Robotic GMAW guns are intended to weld at the same location every cycle by providing a consistent tool center point (TCP). Some products are more durable than others but they all require preventive maintenance to optimize performance and prevent unscheduled downtime for replacing items like contact tips or liners. Air-cooled robotic GMAW guns are the most durable product available. Many applications in the automotive industry, such as suspension components, use thin materials—2 to 4 millimeters—that are ideal for an air-cooled robotic GMAW gun since the typical operating range is approximately 200 to 300 amps at an average of 60 percent duty cycle. Water-cooled products improve performance at higher duty cycles yet they are inferior to air-cooled products from a durability perspective. This is primarily due to the addition of water channels and other mechanical requirements of a water-cooled design. In the automotive industry, it is rare to experience applications that truly require a water-cooled GMAW gun. Even for end users welding thicker base metal (truck frames, for example), they are still likely to be within the comfortable range of an air-cooled GMAW gun. In some cases, however, the addition of water-cooling will help manage excessive heat and prolong the life of welding consumables (e.g., nozzles and contact tips). In these instances, there exists an opportunity to use a hybrid air-cooled/water-cooled gun. This type of product has the underlying construction and durability of an air-cooled robotic GMAW while offering some of the benefits of a water-cooled solution. Regardless of the welding application, it is important for companies to use the most appropriate type of GMAW gun for the job and properly maintain the equipment to ensure a maximum return on investment. Good preventive maintenance procedures include inspection of all connections in the entire system: GMAW gun, wire feeder and ground cables, and more. Other opportunities include regular inspections for proper wire feeding and proactively replacing worn components during scheduled downtime, rather than during production. Such activities can occur prior to a shift beginning and may help avoid unnecessary interruptions to welding during production. As the automotive industry returns to the production levels of several years ago, taking steps to standardize inventory, implement good preventive maintenance techniques and select the right product are means by which companies can become more efficient and “do more with less.”