Maintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take to achieve those goals vary. Still, there is one constant: the value of skilled welders. They are at the heart of the operation and help ensure its success.

Having the right equipment and understanding how to care for it are also important, as is

revisiting the welding process regularly to ensure its efficiency. Companies should take care to watch for common pitfalls that could negatively affect their progress toward streamlining and improving their operation.

Consider these tips to help along the way:

Welder training

With the industry facing an anticipated welder shortage of 400,000 by 2024, providing training to new welders is critical to supporting a productive and profitable MIG welding operation. In many cases, employees being hired are entirely new to welding or only have limited experience. Learning best practices early on is necessary to achieve the best performance and avoid excessive downtime for troubleshooting.

Gaining good weld quality depends on welders knowing proper techniques like gun angle and gun travel speeds and the impact of welding parameters on the process. Even if a company sets lockouts that keep welding parameters within a specific range, it’s valuable for welders to understand the impact voltage, amperage, wire feed speed and shielding gas have on the application.

It’s also important to provide training on other best practices in the MIG welding operation, such as:

- Consulting a checklist for maintenance or equipment checks at the beginning and end of each shift. This can include items like securing weld grounding and checking for gun or cable damage.

- Understanding proper ergonomics to prevent repetitive stress injuries. Having welder input on gun handle types can help with this, too.

- How to correctly install consumables and at what frequency, along with how to identify the signs of contact tip wear.

- Keeping the gun uncoiled and untwisted while using it to help avoid liner movement, which typically leads to wire feeding problems.

- As part of training, encourage welders to be open to asking questions and offer refresher courses to keep skills in top shape.

MIG welding operation, it’s a good

idea to regularly assess each aspect of it.

Assessing the process

To support the long-term efficiency of a MIG welding operation, it’s a good idea to regularly assess each aspect of it.

Time studies, for example, offer excellent insight into the entire workflow and allow companies to record the amount of time each task takes to complete. These studies include a breakdown and analysis of parts handling, welding and more. By recording every activity in the operation, it is possible to see whether each one is adding value. If not, adjustments and re-sequencing can be made.

Analyzing the operation can also help identify the need for more welder training. For instance, if a significant amount of time is spent grinding after welding, it can indicate that there are issues contributing to overwelding or poor weld quality. The company can then take proactive steps for additional welder training to improve quality and reduce or eliminate the need for grinding and rework.

Similarly, if welders are spending more time transferring parts than they are welding or there are bottlenecks of parts entering the welding cell, that indicates the workflow needs to be adjusted. The goal is to minimize the amount of time welders spend handling or double handling parts and helps avoid parts from backing up or having welders sit idle waiting for them.

Improving the organization of the workstation as part of a general assessment can also help improve welding productivity. This could include adjusting welding tables and part racks to be more ergonomic so welders are more comfortable and can weld longer.

Welding gun selection and use

Having the correct MIG welding gun for the application can help enhance performance in a MIG welding operation.

One of the first things to consider is cost. Quality MIG welding guns carry a higher price, but they are worth it in the long term. A better gun (when used properly) lasts longer and can help improve weld quality and efficiency over time. Guns that feature mechanical compression fittings, as opposed to crimped fittings, are a good choice. They typically last longer from wear and tear and can also be repaired if damaged, which saves money on replacement guns.

Be certain to choose a gun with the appropriate amperage rating and duty cycle for the application to prevent overheating. A lower amperage MIG welding gun may be appealing to a welder due to its lighter weight and flexibility; however, it will not be able to withstand an application requiring higher amperages and long arc-on times.

Effectively grounding the weld circuit is another way to gain weld quality and productivity in a semi-automatic welding operation. It can also protect the welding gun from overheating and from wearing out consumables too quickly. Installing the ground clamp as close to the weld as possible and limiting the amount of connections can help to prevent one or more from coming loose over time or creating electrical resistance.

Always choose correctly sized ground cables for the weld circuit and the right type of ground clamp. A C-clamp is a good option as it is a tighter connection versus a spring clamp, which helps prevent arcing at the ground that could lead to an erratic arc. As with other quality components in a MIG welding operation, C-clamps can be more expensive, but they offer a connection that can better protect the gun and save on replacement or repair costs.

Lastly, take care to inspect the welding gun cable regularly for damage and replace as necessary. Nicks or cuts in the cable can expose bare copper, causing a safety hazard of electrical shock, as well as erratic welding issues. Adding a cable jacket cover is a proactive step in avoiding these problems.

The role of consumables and wire

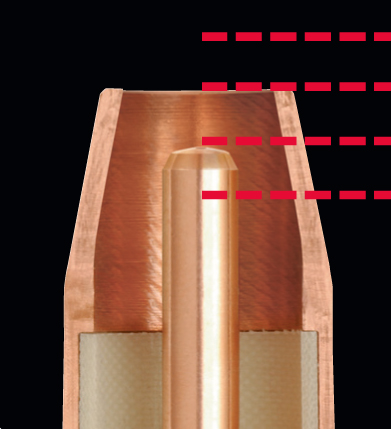

Contact tips, nozzles, gas diffusers and liners all affect MIG welding performance. Ideally, select consumables and wire designed to complement one another as a system. These can help maintain solid connections that provide the best electrical conductivity and arc stability.

Always trim the liner properly — per the guns owner’s manual — to avoid erratic arcs and burn backs or look for liners that lock into place and require no measurement to avoid trimming them too long or too short.

For semi-automatic MIG welding, copper contact tips work well; however, if more tip life is desired or needed, chrome zirconium tips are an alternative to better resist physical tip wear (also known as keyholing). It helps to monitor how often contact tips are being changed to avoid straying too far from the originally planned frequency of tip changeover. If tip changes begin to increase drastically, then this points to incorrect installation of consumables, a liner being cut too short or other damage in the system. Monitoring consumables usage can also help identify when contact tips could still have life left in them. If contact tips are changed too early, this results in unnecessary downtime.

Also consider the wire being used. Quality is key here, too. Less expensive wires often have an irregular cast or helix or an inconsistent layer of lubricant. All of these factors can lead to weld quality issues and additional wear on the contact tips.

Keeping on track

Maintaining an efficient MIG welding operation takes time and resources, but it’s worthwhile to make an investment in welders and equipment to achieve the best results. Continue to monitor the process for improvement opportunities and engage welders whenever possible. Since welders are responsible for moving quality and productivity forward, their ideas can be a valuable asset.

How to Prevent Common Causes of Poor Welding Wire Feeding

How to Prevent Common Causes of Poor Welding Wire Feeding

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost.

Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird-nesting and more. To simplify troubleshooting, it’s best to look for issues in the wire feeder first and move toward the front of the gun to the consumables.

Finding the cause of the problem can sometimes be complicated, however, wire feeding issues often have simple solutions.

What’s happening with the feeder?

When poor wire feeding occurs, it can be related to several components in the wire feeder.

1. If the drive rolls don’t move when you pull the trigger, check to see if the relay is broken. Contact your feeder manufacturer for assistance if you suspect this is the issue. A faulty control lead is another possible cause. You can test the control lead with a multimeter to determine if a new cable is needed.

2. An incorrectly installed guide tube and/or the wrong wire guide diameter may be the culprit. The guide tube sits between the power pin and the drive rolls to keep the wire feeding smoothly from the drive rolls into the gun. Always use the proper size guide tube, adjust the guides as close to the drive rolls as possible and eliminate any gaps in the wire path.

3. Look for poor connections if your MIG gun has an adapter that connects the gun to the feeder. Check the adapter with a multimeter and replace it if it’s malfunctioning.

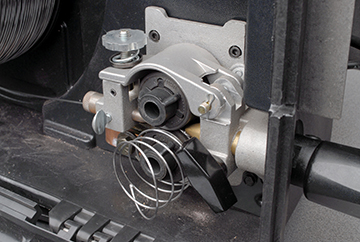

Take a look at the drive rolls

is the wrong size for the wire being used.

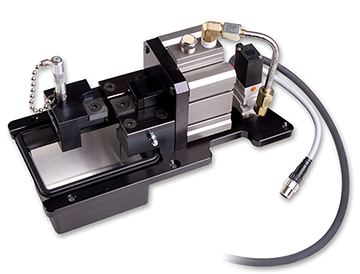

Using the wrong size or style of welding drive rolls can cause poor wire feeding. Here are some tips to avoid problems.

1. Always match the drive roll size to the wire diameter.

2. Inspect drive rolls every time you put a new spool of wire on the wire feeder. Replace as necessary.

3. Choose the style of drive roll based on the wire you are using. For example, smooth welding drive rolls are good for welding with solid wire, whereas U-shaped ones are better for tubular wires — flux-cored or metal-cored.

4. Set the proper drive roll tension so there is sufficient pressure on the welding wire to feed it through smoothly.

Check the liner

Several issues with the welding liner can lead to erratic wire feeding, as well as burnbacks and bird-nesting.

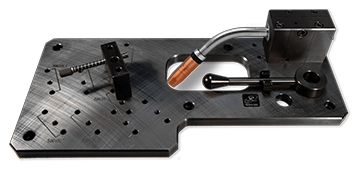

1. Be sure the liner is trimmed to the correct length. When you install and trim the liner, lay the gun flat, making certain the cable is straight. Using a liner gauge is helpful. There are also consumable systems available with liners that don’t require measuring. They lock and concentrically align between the contact tip and power pin without fasteners. These systems provide error-proof liner replacement to eliminate wire feeding problems.

2. Using the wrong size welding liner for the welding wire often leads to wire feeding problems. Select a liner that is slightly larger than the diameter of the wire, as it allows the wire to feed smoothly. If the liner is too narrow, it will be difficult to feed, resulting in wire breakage or bird-nesting.

3. Debris buildup in the liner can impede wire feeding. It can result from using the wrong welding drive roll type, leading to wire shavings in the liner. Microarcing can also create small weld deposits inside the liner. Replace the welding liner when buildup results in erratic wire feeding. You can also blow compressed air through the cable to remove dirt and debris when you change over the liner.

Monitor for contact tip wear

Welding consumables are a small part of the MIG gun, but they can affect wire feeding — particularly the contact tip. To avoid problems:

1. Visually inspect the contact tip for wear on a regular basis and replace as necessary. Look for signs of keyholing, which occurs when the bore in the contact tip becomes oblong over time due to the wire feeding through it. Also look for spatter buildup, as this can cause burnbacks and poor wire feeding.

2. Consider increasing or decreasing the size of contact tip you are using. Try going down one size first, which can help promote better control of the arc and better feeding.

Additional thoughts

Poor wire feeding can be a frustrating occurrence in your welding operation — but it doesn’t have to slow you down for long. If you still experience problems after inspecting and making adjustments from the feeder forward, take a look at your MIG gun. It is best to use the shortest cable possible that can still get the job done. Shorter cables minimize coiling that could lead to wire feeding issues. Remember to keep the cable as straight as possible during welding, too. Combined with some solid troubleshooting skills, the right gun can keep you welding for longer.

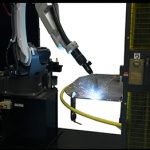

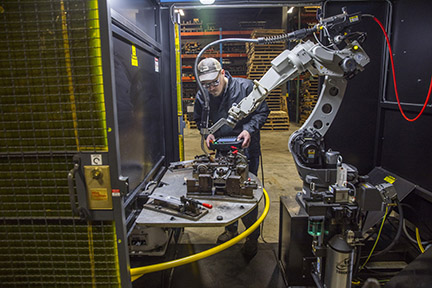

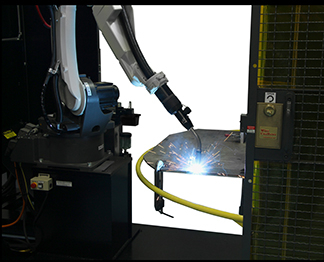

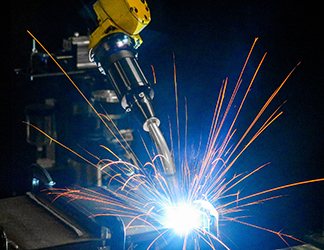

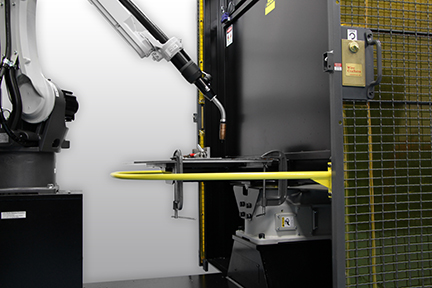

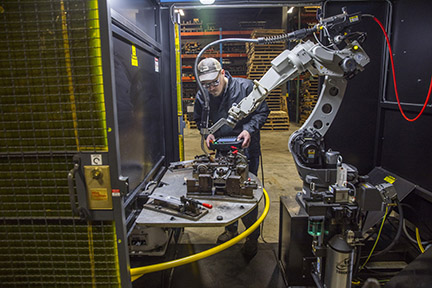

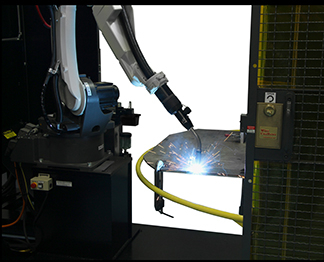

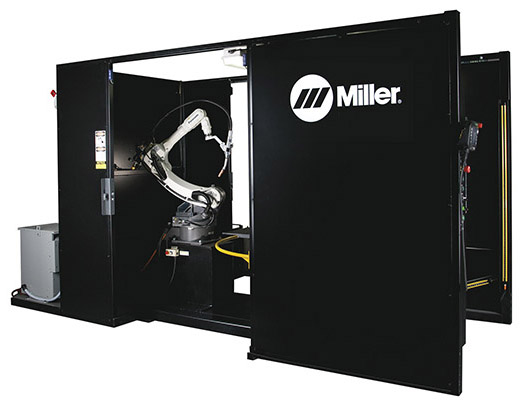

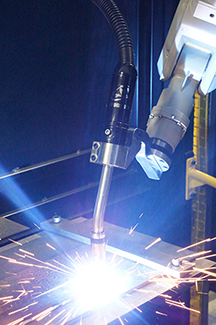

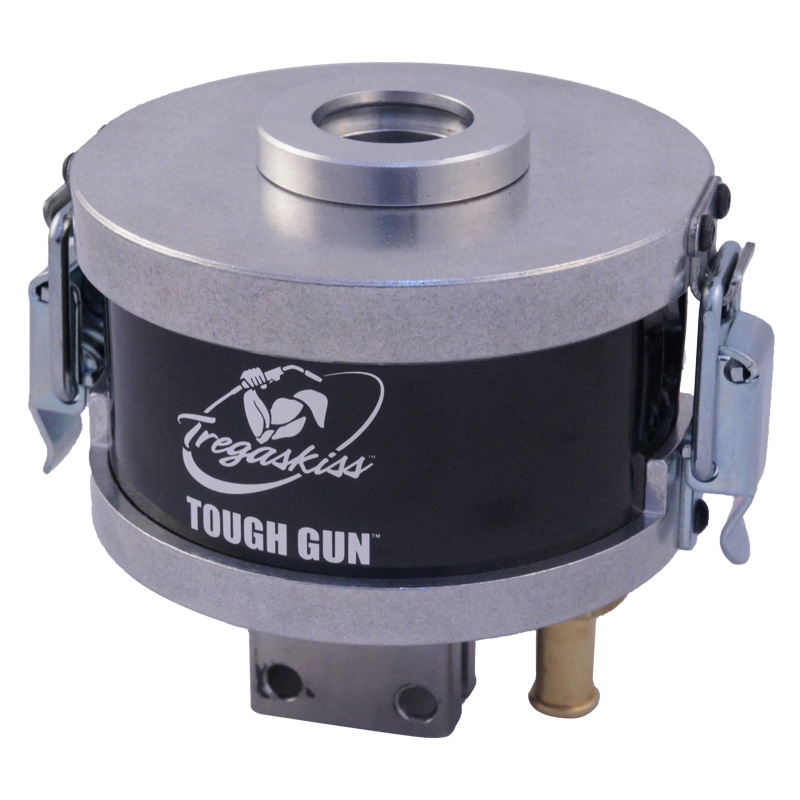

In today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: to address a shortage of skilled labour, to improve quality, to decrease waste and rework, and/or to increase productivity — in short, to seek benefits that provide a competitive edge. Not all companies, however, are successful in the process. Those beginning without a well-thought-out roadmap risk losing valuable time during implementation and operation and may miss the full benefits provided by a robotic welding system. Conversely, companies that begin with a careful examination of their welding needs and existing processes — and develop a detailed plan with clearly established goals — are more likely to achieve success. Planning should include an accurate assessment of parts, work flow and the current facility, as well as an evaluation of the potential return on investment (ROI). Companies should not only look at current needs, but also consider future opportunities to determine the best robotic welding system to scale for potential growth or changes to products they may produce later. In an economy where orders are increasing and welding positions are hard to fill, robotic welding can help maintain or increase productivity. In a semi-automatic welding operation, labour accounts for approximately 70 to 85% of the total cost of welding a part. A robotic welding system can reduce that cost and increase throughput by completing the work of two to four people in the same amount of time — however, companies still require skilled welding operators to oversee the robotic cell. 1. With the right robotic welding system, companies can improve first-pass weld quality and reduce the amount of rework or scrap parts. Depending on the welding wire and mode used, the system may also minimize or eliminate spatter, which reduces the need to apply anti-spatter compound or perform post-weld clean up. 2. A robotic welding system can reduce over-welding, a common and costly occurrence associated with the semi-automatic process. For example, if a company has welding operators who weld a bead that is 1/8-inch too large on every pass, it can potentially double the cost of welding (both for labour and for filler metals). Over-welding may also adversely affect the integrity of the part. 3. Companies can reallocate skilled employees to other production areas to fill open positions and gain additional productivity and efficiencies. 4. Welding automation can also provide a competitive advantage as it may be considered attractive to customers. The improvement in quality may prompt new customers to place orders or lead existing customers to increase their orders with the objective of growing their own businesses. 5. Finally, robots are fast. They don’t have to weld all day to be profitable. That fact improves productivity and the bottom line by making the same number of parts as in a semi-automatic process in less time. When considering an investment in a robotic welding cell, companies should have part blueprints, preferably in an electronic format. Without a blueprint, the part likely won’t meet the basic criterion necessary to ensure repeatability during the manufacturing process. A robotic welding system welds in the same place every time. When a part’s tolerances are unable to hold its position — if there are gap and/or fit-up issues — the company will simply be automating a broken process. This can increase rework or scrap. If a company currently relies on its welding operators to compensate for fit-up issues, it will need to look upstream in the manufacturing process to establish consistency. What processes need to change so these welding operators send uniform parts downstream? Or, if vendors supply the parts, can they guarantee consistency? A streamlined workflow is one of robotic welding’s benefits. To achieve it, companies need to look beyond the weld cell, making certain the facility can accommodate a smooth flow of materials. It makes little sense, for example, to invest in a robotic welding system to increase productivity, but then place it in a corner where employees may have to handle each part multiple times. There should be a consistent supply of parts to avoid moving a bottleneck from one area to another. It is also important to look at the expected cycle time of the robot. Can personnel supply parts to keep up with the demand of the robot’s cycle time? If not, the supply of parts, including where the company stores them and how it moves them, will need to be adjusted. Otherwise, a robot will sit idle waiting for components to come down the line. There is no single welding automation solution that is best for every company. When a company is considering the investment, it should factor in the expected lifetime of the job, the cost of tooling and the flexibility the equipment offers. Fixed automation is the most efficient and cost-effective way to weld parts with simple, repetitive, straight welds or round welds, where the part is rotated with a positioner. If a company wants to reuse the equipment when the current job ends, however, a robotic welding system offers more flexibility. A single robot can store programs for multiple jobs, so it may be able to handle the tasks of several fixed-automation systems. There is a certain volume of parts that justify the investment of welding automation for each company. An accurate assessment of goals and workflow can help determine what that volume is. If a company makes only small runs of parts, robotic welding becomes more challenging. But, if a company can identify two or three components that can be automated, a robot can be programmed to manufacture those parts, offering greater versatility and boosting productivity. This may benefit even small companies that may not have significant volume of a single part. Although a robot is more expensive than a fixed-automation system, it is important to consider the cost of the tooling before deciding between the two. Fixed automation systems can become quite expensive if they require extensive changes to retool a new part so it can be welded consistently. The physical footprint for a robotic welding system and the area needed for parts to flow into the welding cell is typically greater than that of a semi-automatic welding operation. The available space needs to be adequate for the robot, welding power source and other equipment. This helps minimize the need to customize products, such as cables, nozzle cleaning stations (or reamers) or the robotic MIG gun to fit the work envelope. A company with less space can still make welding automation work. One option is to purchase fewer pieces of robotic welding equipment that are capable of performing multiple tasks, such as material handling or vision/scanning systems. A third-party integrator can help determine whether a facility suits the installation of a robotic welding system. System integrators are knowledgeable about facility modifications, including important safety regulations that apply in a company’s region, country or state — in addition to those specified by OSHA and RIA (Robotic Industries Association). In addition to offering advice on facility modifications and helping a company select the right robot, a robotic systems integrator or welding automation specialist can: 1. Help determine if parts are suitable for automation, and, if not, what is required to make them suitable 2. Analyze the workflow and facility to identify potential roadblocks 3. Analyze the true costs involved with the investment, including facility updates and tooling 4. Determine the potential payback of the investment 5. Help identify goals and develop a precise plan and timetable to achieve those goals 6. Explain automation options and help select those that best fit the company’s needs 7. Help select a welding equipment that has the flexibility to maximize travel speed, minimize spatter, eliminate over-welding, provide great arc stability and increase first-pass weld quality Integrators can also help select additional equipment for the robotic welding cell, including positioners, tooling, the robotic MIG gun, welding wire and peripherals. Each item serves a distinct function. The positioner turns, rotates or otherwise moves the part into an optimal position for welding. In many cases, this involves moving the part so that the system can weld in a flat position for optimal deposition efficiency. A positioner can also allow for coordinated motion between the robot and weldment. The tooling holds the part in place during welding and is a critical component of a robotic welding system. The robot arm and robotic MIG gun travel a programmed path each cycle. If the weld joint is out of place because the part is misaligned, it can result in inadequate fusion or penetration and rework or scrap. It is important to design the tooling correctly upfront when investing in a robotic welding cell and monitor it for mechanical wear or heat distortion once it has been put into operation. This helps ensure consistent part fit up so that weld quality doesn’t suffer. The robotic MIG gun should never be an afterthought when considering an investment in welding automation, nor should the welding wire. Both can have a significant impact on productivity and profitability. An integrator can help with the selection based on how the gun and wire perform in conjunction with the rest of the system’s components. The gun will be subject to intense heat and spatter, so it must be durable. It also needs to be the appropriate size to maneuver around the tooling and gain proper joint access. Finally, peripherals, such as reamers, an anti-spatter sprayer and wire cutter are good options to discuss with an integrator prior to making the investment in welding automation. These devices can improve uptime and welding performance by keeping the welding gun consumables free of spatter, operators out of the weld cell and providing consistent wire stickout during welding. Companies cannot simply purchase a robotic welding system and let it go. They need a welding operator or other employee skilled in robotic welding programming. This will likely involve additional training to upgrade his or her skill sets. The good news is, programming a robot today is much quicker than in the past. Simplified teach pendants, along with the availability of desktop programming, help expedite the process and reduce downtime. Despite the ease of programming, however, companies may need to alleviate some existing tasks to allow time for the employee to oversee the robotic welding cell without becoming overloaded with too many responsibilities. Most robot OEMs offer a weeklong training course explaining how to operate the equipment. This course, followed by a week of advanced programming, is recommended when implementing welding automation. If the personnel investigating the prospect of robotic welding determine it’s a good fit, they will likely need to justify the investment to upper management or an owner. Calculating the potential payback is essential. There are several steps to consider. First, determine whether the volume of parts the company needs to produce requires the speed of welding automation. Remember, the key benefit of a robotic welding system is the ability to produce high volumes of quality welds or in smaller facilities to offer the flexibility to weld smaller volumes of multiple parts. Calculate payback by assessing the current volume of semi-automatic parts and cycle times. Compare these to the potential cycle times of a robotic welding system. Again, an integrator or welding automation specialist can help. Establishing the comparison is critical to estimating the potential return on investment. That said, even if a company will produce the same number of parts with a robot, it could justify the investment by the amount of labour it can reallocate elsewhere in the operation for jobs that boost production, eliminate bottlenecks or increase quality. For example, a company could utilize the skills of semi-automatic welding operators to complete challenging welds that are too complicated for a robot to manage. It’s important to factor the bulk cost of shielding gas and welding wire when looking at the potential payback. While there is an initial cost for a shielding gas/manifold system, it can help optimize a company’s robotic welding capabilities in the long term by minimizing downtime for cylinder changeover. The same is true for welding wires. The larger drums — typically ranging from 500 to 1500 pounds — can further reduce costs in a robotic welding cell since they require fewer changeovers and often come with purchasing discounts. Companies need to keep in mind that the benefits of robotic welding can be significant. However, those benefits come at an upfront price. Many companies, especially smaller ones or those that frequently change production lines, need a faster payback — no more than 12 to 15 months is common to justify the investment. If a company will have the same production needs for many years, it can typically justify a longer payback period. Management and owners should discuss their payback goals with a trusted robotic welding integrator as part of the assessment process.

Robotic welding systems continue to gain in popularity due to their ability to increase productivity, improve quality and decrease costs in the right application. But they also offer a way to address a shortage of skilled labor for manual operations. Welding automation provide companies with a means of staying competitive in a demanding marketplace, while using their existing and potential workforce to oversee the weld cell. With more and more robotic welding systems being implemented — the Robotics Industries Association (RIA) cited that 20% of all industrial applications had robotic welding cells as of 2017 — comes the need for increased attention to safety. From the robotic welding gun and peripherals to the robot itself, following safety best practices is essential. Statistically, welding automation is safer than manual or semi-automatic welding. However, operators overseeing the robotic welding cell must still remain vigilant. This is particularly true when performing nonstandard operations; these include programming, maintenance and any other tasks that involve direct human interaction with the robot. Conducting a thorough welding risk assessment helps identify potential safety hazards associated with a specific robotic welding system (whether it is a pre-engineered or custom cell) and is a critical first step in establishing a safer welding environment. This assessment provides a baseline for implementing solutions for identified risks and establishing appropriate welding safety training. In addition, it helps companies maintain compliance with safety standards, which most importantly protects employees but also protects the bottom line. Noncompliance and/or safety violations that can lead to injury become can be costly in terms of fines and workers’ compensation. Companies can obtain welding safety resources through the American Welding Society (AWS), including Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, a free download at aws.org. The National Fire and Protection Association (NFPA) also offers resources. RIA follows American National Standards Institute (ANSI) standards and offers safety seminars and webinars. RIA also provides information on industrial machinery and guarding, as well as guidelines to help companies, including the American National Standard for Industrial Robots and Robot Systems – Safety Requirements, ANSI/RIA R15.06-2012. The Occupational Safety and Health Administration (OSHA) is another valuable safety resource. Many robotic welding integrators or robotic welding system manufacturers offer training for the safe use of their equipment, including how to test safety functions and at what frequency. They also provide manuals and safety standards for their systems. It is critical to read and follow these thoroughly. Manufacturers of robotic MIG welding guns often integrate design elements into these products to aid in their safe use. These elements are intended to protect operators during routine maintenance and minimize or eliminate the need to enter the weld cell to complete tasks. For example, guns that are compatible with front-loading liners help improve safety in a robotic welding cell. These liners can be installed from outside the weld cell — there is no need to climb over tooling or maneuver around the robot to complete replacement. Operators or maintenance personnel also don’t need to remove electrical connections to replace components during the process. An insulating disc is another important safety feature in select guns. It helps protect operators from the welding current during maintenance and protects the robot from the current, limiting potential damage. In addition to integrated safety features, there are some key best practices for working with robotic welding guns, consumables and reamers (or nozzle cleaning stations). First and foremost, always de-energize the robotic welding system when installing a robotic MIG gun or consumables, and follow all lockout/tagout procedures. When possible, it’s ideal to have a window or opening that allows consumables to be changed or inspected from outside the weld cell. When possible, it’s ideal to have a window or opening that allows consumables to be changed or inspected from outside the weld cell. If this isn’t feasible, programming the robot to stop near the weld cell door simplifies consumable changeover and eliminates the need for the operator to enter the cell, maneuver around tooling or climb on anything to complete the job. The appropriate personal protective equipment (PPE) is also important when changing over consumables or the welding wire. The nozzle and contact tip may be hot, and there is the risk of the welding wire puncturing the operator. Leather or other thick work gloves are a must, and safety glasses should be worn at all times. Always use the proper tool to change over the nozzle and contact tip. A pair of welpers is recommended. When performing maintenance on a reamer, begin by resetting the equipment to a home state, de-energizing it and following lockout/tagout procedures. Be certain there is no air or electricity supplied to the reamer. When changing over cutter blades, always wear gloves and use two wrenches to remove and install them. Reset the reamer to a home state when finished. This is an important last step, as the reamer will automatically complete a cycle as soon as it receives a start signal and is reenergized. Welding operators and maintenance personnel should familiarize themselves with the emergency stops on a robotic welding system as a first safety step. The number and location of these stops varies by system. For example, welding cells typically have an operator station emergency stop that ceases all robot functions and turns off the robot servo power, along with an emergency stop on the teach pendant. Operators should test these emergency stops periodically, although testing too frequently is stressful on the mechanics of the robotic welding system. Understanding brake release procedures is also critical. RIA sets standard requirements for these; however, every robotic welding system is different, and the location of the override buttons may vary. As when interacting with a robotic MIG welding gun, consumables or reamer, always follow proper lockout/tagout procedures before entering the robotic welding cell. Many systems have multiple lockout/tagout locations that are indicated by stickers. Some pre-engineered welding cells feature sliding programming access doors with magnetic keys that indicate that they are fully open and ready to be locked out prior to maintenance, helping to prevent pinch points or a trap hazard. A built-in awareness barrier in pre-engineered cells is another means of aiding operator safety. This hooped barrier inside the weld cell covers the sweep area of the indexing table. Its purpose is to protect the operator from pinch points during teaching operations by separating the him or her from the space between the robot and the wall of the weld cell. For robotic systems that are not enclosed, guards around the cell are necessary. These can take the form of physical barriers, like perimeter fencing or light curtains and/or electronic guarding such as area scanners that stop the robot when an operator is present in a specific area of the system. Lastly, robotic integrators and robotic welding system manufacturers provide risk assessment documentation, typically in the operator’s manual. It is important to review this assessment thoroughly and train employees on the proper techniques to mitigate any identified risks. For example, programming the robot introduces mechanical hazards such as the potential for pinching or impact, which can be addressed by standing a safe distance outside of the weld cell or by using a slower teach speed if offered on the teach pendant. In addition to the best practices outlined for robotic MIG welding guns, consumables and systems, there are steps to further protect employees. Safety in welding automation should be top of mind among operators, management and maintenance personnel. Ongoing training needs to be a priority, whether it is conducted through company programs or seminars offered by outside resources. The goal is to ensure that everyone involved with the robotic welding system is playing an active role in employing best practices. When they are followed properly, the result is a safer work environment and a stronger bottom line.

Using the wrong shielding gas for MIG welding applications — or having improper gas flow — can significantly impact weld quality, costs and productivity. Shielding gas protects the molten weld pool from outside contamination, so it’s critical to choose the right gas for the job. Learn more about which gases and gas mixes are best suited for certain materials, along with some tips for optimizing gas performance — and saving money — in your welding operation.

It’s important for new welding operators to establish proper MIG techniques in order to achieve good weld quality and maximize productivity. Safety best practices are key, too. It’s just as important, however, for experienced welding operators to remember the fundamentals in order to avoid picking up habits that could negatively impact welding performance. From employing safe ergonomics to using the proper MIG gun angle and welding travel speeds and more, good MIG welding techniques provide good results. Here are some tips. A comfortable welding operator is a safer one. Proper ergonomics should be among the first fundamentals to establish in the MIG welding process (along with proper personal protective equipment, of course). Ergonomics can be defined, simply, as the “study of how equipment can be arranged so that people can do work or other activities more efficiently and comfortably.”1 The importance of ergonomics for a welding operator can have far reaching effects. A workplace environment or task that causes a welding operator to repetitively reach, move, grip or twist in an unnatural way, or even stay in a static posture for an extended period of time without rest, can lead to repetitive stress injuries with life-long impacts. Proper ergonomics can protect welding operators from injury while also improving productivity and profitability of a welding operation by reducing employee absences. 1. Using a MIG welding gun with a locking trigger to prevent “trigger finger,” which is caused by applying pressure to a trigger for an extended period of time. 2. Using a MIG gun with a rotatable neck to help the welding operator move more easily to reach a joint with less strain on the body. 3. Keeping hands at elbow height or slightly below while welding. 4. Positioning work between the welding operator’s waist and shoulders to ensure welding is being completed in as close of a neutral posture as possible. 5. Reducing the stress of repetitive motions by using MIG guns with rear swivels on the power cable. 6. Using different combinations of handle angles, neck angles and neck lengths to keep the welding operator’s wrist in a neutral position. The proper welding gun or work angle, travel angle and MIG welding technique depends on the thickness of the base metal and the welding position. Work angle is “the relationship between the axis of the electrode to the welders work piece.” Travel angle refers to employing either a push angle (pointing in the direction of travel) or a drag angle, when the electrode is pointed opposite of travel. (AWS Welding HandBook 9th Edition Vol 2 Page 184)2. Flat position For T-joints, hold the gun at a work angle of 45 degrees and for lap joints a work angle around 60 degrees is appropriate (15 degrees up from 45 degrees). Horizontal position Vertical position The uphill direction is used for thicker material when greater penetration is needed. A good technique for a T-Joint is call the upside-down V. This technique assures the welding operator maintains consistency and penetration in the root of the weld, which is where the two pieces meet. This area is the most important part of the weld.The other technique is downhill welding. This is popular in the pipe industry for open root welding and when welding thin gauge materials. Overhead position Wire stickout and contact-tip-to-work distance Proper contact-tip-to-work distance (CTWD) is also important to gaining good welding performance. The CTWD used depends on the welding process. For example, when using a spray transfer mode, if the CTWD is too short, it can cause burnbacks. If it’s too long, it could cause weld discontinuities due to lack of proper shielding gas coverage. For spray transfer welding, a 3/4-inch CTWD is appropriate, while 3/8 to 1/2 inch would work for short circuit welding. Welding travel speed With a welding travel speed that’s too fast, welding operators will end up with a narrow, convex bead with inadequate tie-in at the toes of the weld. Insufficient penetration, distortion and an inconsistent weld bead are caused by traveling too fast. Traveling too slow can introduce too much heat into the weld, resulting in an excessively wide weld bead. On thinner material, it may also cause burn through. When it comes to improving safety and productivity, it’s up to the experienced veteran welding operator as much as the new welding to establish and follow proper MIG technique right. Doing so helps avoid potential injury and unnecessary downtime for reworking poor quality welds. Keep in mind that it never hurts for welding operators to refresh their knowledge about MIG welding and it’s in their and the company’s best interest to continue following best practices. 1. Collins Dictionary, “ergonomics,” collinsdictionary.com/dictionary/english/ergonomics.

The potential advantages of robotic welding are well known — increased productivity, improved quality and greater cost savings compared to semi-automatic welding. But the question is: How do companies best implement this technology to gain these benefits? And how can they ensure a quick return on the investment (ROI)? Simply stated, planning. More preparation upfront helps minimize the cost and time for correcting errors in the robotic welding system once it has gone into production. From the welding power source to the robot or weld process to the gun and consumables, each component should be thoroughly researched to make sure it is feasible to operate in the weld cell — not just on paper, but in reality. Take advantage of turnkey integrators who run their own process and capability studies. They can provide useful double checks to a plan and often conduct reach studies that model the weld tooling and workpiece. These mock up how the robot would weld in the finished system to test the gun reach and the overall efficiency of the process. Also remember, success in robotic welding is as much a matter of doing the right thing as it is avoiding pitfalls that could hinder the efficiency of the operation. With planning comes budgeting. A robotic welding cell may be installed on time, produce good weld quality and meet cycle time, but if the implementation and use of the system is over budget it will be an uphill battle to gain a good ROI. Consider the associated goals to help establish a feasible ROI. For example, a company with the goal of producing 1000 parts a day needs to determine how much it can make from those parts. From there, it would subtract the cost of utilities and labor, along with the cost to make the product and the cost of raw materials, to determine a budget on equipment costs that would make the company profitable. If this equipment will only be used for 5 years, the company may need a quicker ROI than if it’s planning to use the robotic welding system for 10 years or more. Companies can make the most of their budget by considering equipment that could be reused. This can cut down on the investment in the long run. Robots can have an extensive life if maintained well, allowing them to be re-purposed from project to project. The same holds true with welding power sources and nozzle cleaning stations. Ultimately, ROI depends on the company and what practices it follows for making profit. Some may be able to allow the equipment to take 18 months or more to pay for itself if the company plans on re-using or re-purposing the welding robots on multiple platforms over the next 10 years. Others may stand by the goal of a one-year ROI, which is common. Proper training is important for keeping a robotic welding system running successfully and profitably in the long term. Robot integrators and other equipment manufacturers often offer training as part of the implementation process. This training provides welding operators with a knowledge of robotic welding in general, as well as providing the information they need to operate the robot effectively for the application at hand. A well-trained operator will also be able to determine ways to maximize the efficiency of the robotic weld cell. They do this by troubleshooting and resolving issues quickly, keeping the robot online and supporting greater productivity and cost savings. Likewise, train welding operators to implement PM for the robotic gas metal arc welding (GMAW) gun to gain longer life, reduce downtime and achieve more arc-on time. Regularly check that the gun connections, consumables and power pin are secure. Look for any signs of power cable wear and replace if necessary.Training geared toward the preventive maintenance (PM) of a robotic welding system and the weld cell is also key. For example, spatter build-up on the robotic welding gun can cause grounding issues and build-up on tooling may lead to dimensional movement of the steel from cycle to cycle. The latter can block the datum placements causing gun reach issues. In a worse-case scenario, spatter builds up on equipment over time, creating solid formations that are difficult to remove and prevent the re-use of the equipment. To avoid these problems, train operators to follow a regular cleaning schedule for the weld cell and the equipment. There are several common mistakes that can negatively affect productivity and quality in a robotic welding system. Knowing how to avoid these can help companies make the most out of the equipment and gain greater success. Consider the following: 1. Implementing the wrong equipment in a robotic welding cell can lead to spending more money than is required. Be sure the power source, robotic GMAW gun and consumables are rated for the application. Doing so helps minimize the risk of premature equipment failures that can lead to unplanned downtime and costly equipment replacement. For example, if a company selects an air-cooled system, but actually requires a water-cooled system for the application, it could incur unnecessary costs to repair or upgrade a failed robotic GMAW gun system that cannot handle the heat. 2. Underutilizing the robotic welding system can prevent companies from realizing their full productivity potential. Robotic welding systems should be programmed to maximize the arc-on time during the weld process cycle. In some cases, it may be possible to have fewer robots that weld for slightly longer cycles. This helps drop the initial implementation costs. Take this example. A company has four robots in cell welding at 30 inches per minute with a cycle time of 60 seconds. These robots are inefficient since they are only welding half of the cycle time. That could be due to the positioner rotating for weld access, too slow of robot air cut movements, poor welding angles or other limiting factors. In this scenario, the total length of completed welds for all four robots is 60 inches (30 in. / min. x 1 min. / 60 seconds x 30 seconds of welding per robot = 15 inches of weld per robot). An alternative here is to keep the cycle time at 60 seconds and drop down to three robots by improving items like the weld angles, creating quicker air cuts between welds, utilizing gun reaming during positioner movements and more. Now with improvements, the robots could weld at an average of 35 inches per minute for 35 seconds each cycle. That provides an average of 20 inches of weld per cycle per robot, allowing for the same total of 60 inches of weld with one less robot. 3. Underutilizing available labor can also hinder productivity. While companies should take care not to overload operators, it’s important to balance manpower in robotic welding process so that employees are efficient and busy at the same time. If an operator is idle waiting for the weld cycle to complete, there could be room for process improvements by allocating labor to other activities near the weld cell. 4. Poor tooling design can impede quality. Thoroughly plan the tooling design and understand how the parts being welded will impact it. Different parts and materials react differently to heat and may draw, flex or bend during the welding process. Factor in how much heat a given weld sequence generates. The tooling will have to be designed with these in mind. If possible, design tooling to permit welding in the flat or horizontal position with appropriate robotic GMAW gun access. This allows for faster and more consistent results. Finally, remember, less expensive tooling may be attractive when looking at upfront costs, but it can be a pitfall later if it doesn’t meet the demands of the job. 5. Overlooking activities outside the robotic weld cell can be detrimental. Plan for part inspection and cosmetic rework, as well as the final stages of palletizing the product if that is part of the operation. Some of these processes can be automated or manual labor driven. These are key stages in a robotic welding operation that can quickly become bottlenecks that cause the entire process to slow down. These bottlenecks can also add unplanned manpower or equipment costs, which can become expensive. Remember that no plan for welding automation can be successful without a good schedule for its implementation. Being thorough is more important than being fast. Set realistic goals for completing the installation of the robotic weld cells and don’t rush or over-complicate the process. For first-time investors in robotic welding starting small can also help ensure greater success. Once the robotic weld cell or cells begin operating, keep in mind that the startup may not be perfect. There may be adjustments required to optimize performance to gain the best productivity and quality.

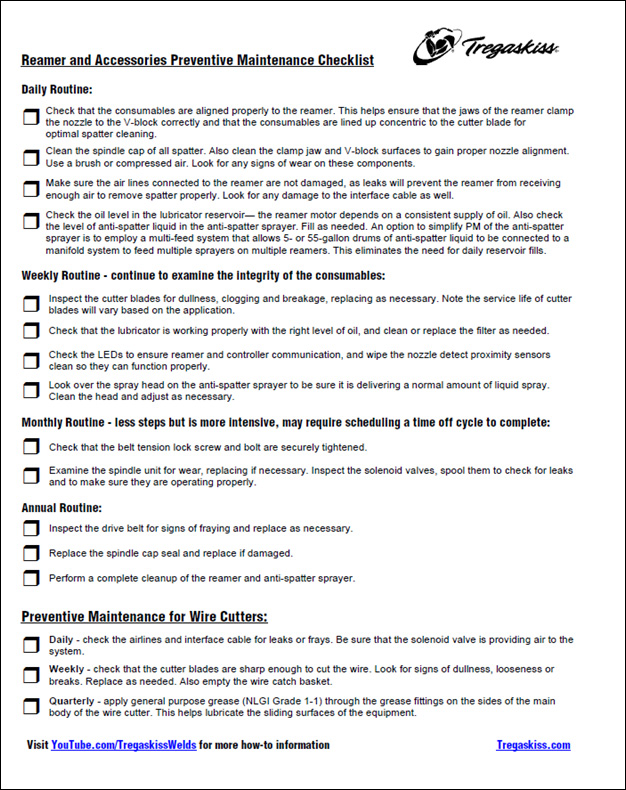

From reamers or nozzle cleaning stations to wire cutters and anti-spatter sprayers, welding peripherals and accessories can contribute significantly to the success of a robotic welding operation. In addition to improving weld quality, they can also help companies maintain high levels of productivity. Reamers, in particular, are most prevalent in automotive manufacturing, where uptime and quality are critical. This peripheral cleans the welding consumables — for example, welding nozzles and gas diffusers — free of spatter, and most automotive welding operations rely on the process after virtually every weld cycle. Other industries, such as heavy equipment manufacturing, also employ reamers and other peripherals in their robotic welding operations, as do some general manufacturers. It’s not by chance that peripherals work the way they do. Like any equipment, caring for them with routine preventive maintenance (PM) is important to gaining optimal performance and longevity. A reamer requires regular attention since it operates frequently during the weld cycles. Its job is important though, as it performs essential welding nozzle cleaning that helps keep the robotic welding cell up and running and quality on par. With the PM for this equipment also comes PM for its associated accessories: the lubricator, cutter blades and anti-spatter sprayer. All require varying levels of PM activities — some daily, weekly, monthly or yearly. In addition to inspecting the consumables for wear and replacing as needed, follow this PM routine on a daily basis: On a weekly basis, continue to examine the integrity of the consumables and follow these guidelines: Monthly PM for reamers and accessories requires less steps but is more intensive. It may require scheduling a time off cycle to complete. Lastly, on an annual basis: While it may seem time-consuming to implement these PM measures, they can typically be completed during routine pauses in production. More intensive activities can be scheduled so as to prevent interruption to production. Ultimately, the PM is time well spent and can help protect the investment in the reamer and its accessories. Wire cutters are increasingly being used in automotive and other manufacturing operations. This equipment is integrated into a reamer configuration and used in conjunction with a wire brake on the robotic MIG gun. The wire brake prevents the welding wire from moving, while the wire cutter cuts it at a set distance. This allows for a consistent wire stickout so the robot can touch sense and track the joint before welding. The results are more accurate weld placement and smooth arc starting. PM for wire cutters is relatively simple. Peripherals like reamers with anti-spatter sprayers and wire cutters can help companies realize a greater return on their investment in a robotic welding system. They aid in high weld quality, minimize rework and help meet productivity goals. Train welding operators to follow recommended PM activities as a part of a routine care of the weld cell. The time and cost to care for them properly will be small in comparison to the improvements they can provide to the bottom line.

Every operation wants to avoid downtime, as well as the cost for troubleshooting problems in the robotic welding cell. But sometimes issues happen, whether it’s due to equipment failure or human error. Since most companies invest in welding automation to boost throughput and profitability, getting a robotic welding cell back online as quickly as possible is critical to production and the bottom line. The first things to consider are whether anything has changed in the welding process or with the equipment, or if the operator has recently reprogrammed the robot. In many cases, evaluating the most recently changed variable can help you pinpoint an issue’s cause. After that, analyzing some of the most frequent sources of trouble in the robotic weld cell can help you get to the root of the problem sooner. Consider these five common issues and ways to fix them. A: The material being welded and the parameters being used affect welding consumables’ longevity. But if it seems that nozzles, contact tips, diffusers or liners aren’t lasting their typical life or are performing poorly, there could be several causes. Check all connections between welding consumables and tighten them as needed. A loose connection increases electrical resistance and generates additional heat, which can shorten consumable life and cause poor performance. It’s especially important to ensure consumables are properly tightened when the application involves long welds or welds on thick materials, since any rework due to quality issues will cost more time and money in these cases. Common contact tips issues, such as burnback, are often caused by a too-short liner. Always follow the manufacturer’s instructions for liner trimming and installation, and use a liner gauge to confirm length when possible. Over time, debris and spatter buildup inside the liner can contribute to shortened contact tip life. It’s important to create a schedule for changing liners, just as you would for other consumables. If you’re frequently experiencing weld defects like porosity or lack of penetration, this can also stem from a consumables issue. Make sure the contact tip and nozzle are free of debris and replace them as needed. A: Erratic or poor wire feeding in robotic welding is a common issue that can ultimately result in poor weld quality. Poor wire feeding can have many causes. Cutting a liner too short is particularly problematic when robotic welding with smaller diameter wires, which have less column strength. Extreme articulation of the robotic MIG gun can also lead to poor wire feeding. Program the robotic MIG gun cable to stay as straight as possible. The robot may not weld quite as fast, but proper gun orientation helps minimize downtime for feeding problems. Excessive conduit length and multiple bends or junctions can cause poor wire feeding as well. With the drive rolls open, you should be able to pull the wire through the contact tip by hand with minimal effort. If you need to pull with two hands or put your bodyweight into the process, that indicates interference with the wire path between the wire drum and the contact tip. Check for bends tighter than 90 degrees, multiple junctions between sections of conduit or worn conduit sections that can increase drag on the wire. Ideally, the conduit between the drum and the wire feeder should be less than 20 feet, with no junctions or tight bends. Improper drive roll selection and tension setting can also lead to poor wire feeding. Consider the size and type of wire being used and match that to the drive rolls. Inspect drive rolls for signs of wear and replace them as necessary. A: Whether you have a through-arm robotic welding system, where the cable is routed through the robotic arm, or a standard over-the-arm robotic welding system, premature power cable failure can happen. A power cable that becomes kinked or worn can fail and short-out against the robot casting, leading to costly repairs. To help prevent premature cable wear, consider the programmed path of the robot as well as the power cable’s length. If the robot’s movements cause the cable to bunch up or kink, it can cause the power cable to fail. If the power cable rubs against tooling or catches on components during the programmed cycle, this can also cause premature failure. A: In robotic welding, TCP refers to the location of the end of the welding wire with respect to the end of the robot arm. If you are experiencing inconsistent welds or welds that are off-location, this may stem from a problem with TCP. If the robotic MIG gun neck is bent or damaged during a collision in the weld cell, this can result in TCP issues. Use a neck-checking fixture or neck alignment tool to help ensure proper angle of the neck bend. Also, be sure the neck and consumables are installed and torqued properly. Failure to do so may affect TCP. However, a problem with off-location welds isn’t always caused by TCP issues. Improper fixturing or part variations may also be the root cause. If a TCP check using the robotic program turns up with no issues, a part or position variation is the likely culprit. A: Companies often implement peripherals, such as reamers or nozzle cleaning stations, to optimize robotic welding performance and get more life out of consumables. But a problem with the reamer can cause spatter buildup on the consumables. Reamers can perform poorly for three common reasons: Problems in the robotic welding cell can be as simple as a loose contact tip or more complex like incorrect TCP. Understanding the steps for proper troubleshooting helps narrow down potential causes and can prevent replacement of components that don’t need replacing — so the operation can save money and quickly get back to producing quality parts. Learn more from the Tregaskiss Troubleshooting Guide.

Implementing robotic welding can significantly improve a manufacturing operation’s productivity and weld quality, but what are the robotic welding basics you should know to be successful? From choosing the right welding wire to establishing proper tool center point (TCP), many variables play a role in optimizing robotic welding cells to produce the best results. Shaving even a few seconds from each weld cycle can save time and money. Minimizing the unplanned downtime for adjustments or repairs in the weld cell can also have a substantial impact on your bottom line. Success with robotic welding requires a well-researched plan. The more planning done upfront, the less time and money you could spend later making fixes and process improvements. Learning some basic tips for setting up a robotic weld cell can help to establish a repeatable and consistent process — so your operation can produce quality welds, reduce rework and maximize its investment. Proper weld settings for the application are based on factors including wire size and material thickness. Some welding power sources offer technology that allows welders to simply input the wire size and material thickness, and the machine will suggest recommended parameters for the application. Without this technology, finding the correct parameters can involve a bit of trial and error. Sometimes the robot manufacturer, welding power source manufacturer or system integrator can assist in choosing and testing specific materials to provide a starting point for the proper welding parameters. Utilize the experience of these partners to help you arrive at the best starting point and be prepared for the future. The choice of filler metal for a robotic welding system can significantly impact productivity, weld quality and the overall investment. Selecting the right wire for a robotic application is typically based on the material type and thickness, as well as the expected outcomes for the welded part. Welding equipment and filler metal manufacturers often offer charts to help you match a welding wire to your process needs. While solid wire has been the industry standard in robotic welding for many years, metal-cored wire is an alternative that can offer productivity and quality improvements in some applications, particularly in the manufacture of heavy equipment and automotive exhaust, chassis and wheels. However, be aware that each wire type offers pros and cons for certain applications, so it’s important to research the type that is best suited to your application. Robotic welding guns and consumables, including the nozzle, contact tip and gas diffuser, have a huge impact on performance in a robotic weld cell. The right combination can reduce unplanned downtime and improve overall efficiency of the cell. Be sure the welding gun is rated with enough duty cycle and amperage for the application. To avoid excessive wear and premature failure, the gun should not rub against any part of the system or another robot in applications where multiple robots are being used on the same tooling. Robotic welding systems typically operate at higher duty cycles than semi-automatic welding applications, and they may utilize transfer modes that are especially harsh on consumables. Consider using heavy-duty consumables that are more heat-resistant than standard-duty consumables. Chrome zirconium contact tips or tips specifically designed for pulsed welding processes are good options. In addition, ensure all consumables are properly installed and tightened. Improper or loose connections produce more electrical resistance and heat that causes faster consumable wear with premature failures. Another common failure in robotic welding is improper liner installation. Always follow the manufacturer’s directions for liner installation and cut length. A liner that is cut too short can cause premature failures of other consumables in the system. Make sure there is good cable grounding in the weld cell to help prevent potential problems as the cell ages. There are two cables running from the welding power source; one is attached to the wire feeder and the other is grounded to the tooling. Often, these cables are long and run from the shop floor to an elevated platform or through wire trays. The section of cable running up the robot or running to a positioner will constantly move — causing greater wear over time. Using a junction with high-flex ground cable at the base of the robot or the workpiece can save time and money in downtime and repair. With this solution, there is only a 6-foot section of cable to replace when it wears out, rather than replacing possibly 50 feet or more of ground cable that runs all the way back to the power source. However, keep in mind you should have as few breaks or junctions in the grounding cable as possible to maintain a better electrical connection. When mounting a ground cable to the welding workpiece, it can be helpful to use copper anti-seize lubricant, sometimes referred to as copper slop. This supports the transfer of electrical current and helps prevent the mounting point from fusing together or deteriorating over time. The lubricant can be useful in all areas where there may be grounding current running through pins or any other semi-permanent contact points. Proper cable management for the guns can also greatly extend cable life. The more any cable bends and flexes, the more wear and tear will occur — ultimately shortening cable life due to high heat and resistance. Work to minimize cable bending and flexing in your robotic process and tooling design. For repeatable and consistent weld quality, it’s critical to establish and maintain proper TCP. Welding operations can set their own standards for the acceptable amount of TCP drift, depending on the application and type of weld being made. When considering the tolerance of TCP variation, an acceptable starting point can be half the thickness of the wire diameter. Many robotic systems today can use touch-sensing features to monitor TCP and determine how far it has moved from the original programmed settings. If a gun is determined to be out of the acceptable TCP range, the gun neck can be removed and recalibrated offline to factory specifications with a neck straightening fixture. Some systems also provide the capability to adjust TCP automatically with the robot. A third option is to leave the gun in place and adjust the robot teaching to accommodate the modified TCP. This is the most time-consuming solution and, therefore, often not acceptable for the manufacturing operation. It also requires the need to reprogram the robot if new factory specifications for TCP or a new neck are ever put into place — which is why this method is typically the last resort. Set a schedule or standard for checking TCP, whether it’s every weld cycle, once a shift or even every time the torch goes through a reamer cycle. The length of time between checks is a matter of preference and weighing your priorities. It can be time-consuming to check every weld cycle, but this can save money in lost scrap and rework if a problem is found before welding occurs. The initial programming of the robot’s welding path can also involve much trial and error. When programming the path, consider the application, material type, welding process being used and gap size that must be filled. The weld quality and amount of spatter created are also impacted by the travel angle and whether it’s a pull or push weld. It can take time to dial in the correct path to achieve the desired quality. After setting the home positions in the robotic program, it’s recommended to have the robot move to perch points or ready-to-enter points that are safely away from any potential collision points, so the system can move quickly with air cut moves to and from these points. When programming the robot to move to a weld, it’s common to set the approach point just above the weld start location. Have the robot approach the start location at a slower and safer speed with the arc on. This approach position provides a good lead-in and typically won’t require adjustment unless the weld is relocated. Some robotic welding systems include technology that aids in setting the initial robot path. The robot’s welding location can play a role in premature failure of the gun. If the robot is welding with a lot of flex in the gun at a tight angle, this can cause it to fail much faster. Minimizing robot axes five and six during welding can help extend gun life by reducing wear. Proper part fit-up in the upstream process is critical to consistent weld quality and robot path programming. Inconsistent fit-up or large gaps between the parts lead to weld quality issues such as burn-through, poor penetration, porosity and others — resulting in additional unplanned downtime to deal with these problems. Large gaps between the parts may also require double weld passes, adding to cycle times. From wire and consumable selection to proper cable management and TCP, many variables play a role in weld quality and ultimately, the success of your robotic welding system. Careful planning at the start of the process and continued monitoring of these key factors helps optimize performance — so you can get the most from your robotic welding investment.

MIG welding, like any other process, takes practice to refine your skills. For those newer to it, building some basic knowledge can take your MIG welding operation to the next level. Or if you’ve been welding for a while, it never hurts to have a refresher. Consider these frequently asked questions, along with their answers, as welding tips to guide you. The welding wire size and type determines the drive roll to obtain smooth, consistent wire feeding. There are three common choices: V-knurled, U-groove and V-groove. Pair gas- or self-shielded wires with V-knurled drive rolls. These welding wires are soft due to their tubular design; the teeth on the drive rolls grab the wire and pushes it through the feeder drive. Use U-groove drive rolls for feeding aluminum welding wire. The shape of these drive rolls prevents marring of this soft wire. V-groove drive rolls are the best choice for solid wire. To set the drive roll tension, first release the drive rolls. Slowly increase the tension while feeding the wire into your gloved hand. Continue until the tension is one half-turn past wire slippage. During the process, keep the gun as straight as possible to avoid kinking the cable, which could lead to poor wire feeding. MIG welding wires vary in their characteristics and welding parameters. Always check the wire’s spec or data sheet to determine what amperage, voltage and wire feed speed the filler metal manufacturer recommends. Spec sheets are typically shipped with the welding wire, or you can download them from the filler metal manufacturer’s website. These sheets also provide shielding gas requirements, as well as contact-to-work distance (CTWD) and welding wire extension or stickout recommendations. Stickout is especially important to gaining optimal results. Too long of a stickout creates a colder weld, drops the amperage and reduces joint penetration. A shorter stickout usually provides a more stable arc and better low-voltage penetration. As a rule of thumb, the best stickout length is the shortest one allowed for the application. Proper welding wire storage and handling is also critical to good MIG welding results. Keep the spool in a dry area, as moisture can damage the wire and potentially lead to hydrogen-induced cracking. Use gloves when handling the wire to protect it from moisture or dirt from your hands. If the wire is on the wire feeder, but not in use, cover the spool or remove it and place it in a clean plastic bag. Contact tip recess, or the position of the contact tip within the MIG welding nozzle, depends on the welding mode, welding wire, application and shielding gas you are using. Generally, as the current increases, the contact tip recess should also increase. Here are some recommendations. A 1/8- or 1/4-inch recess works well for welding at greater than 200 amps in spray or high-current pulse welding, when using a metal-cored wire and argon-rich shielding gases. You can use a wire stickout of 1/2 to 3/4 inches in these scenarios. Keep your contact tip flush with the nozzle when welding less than 200 amps in short circuit or low-current pulse modes. A 1/4- to 1/2-inch wire stickout is recommended. At 1/4-inch stick out in short circuit, specifically, allows you to weld on thinner materials with less risk of burn-through or warping. When welding hard-to-reach joints and at less than 200 amps, you can extend the contact tip 1/8 inch from the nozzle and use a 1/4-inch stickout. This configuration allows greater access to difficult-to-access joints, and works well for short circuit or low-current pulse modes. Remember, proper recess is key to reducing the opportunity for porosity, insufficient penetration and burn-through and to minimizing spatter. The shielding gas you choose depends on the wire and the application. CO2 provides good penetration when welding thicker materials, and you can use it on thinner materials since it tends to run cooler, which decreases the risk of burn-through. For even more weld penetration and high productivity, use a 75 percent argon/25 percent CO2 gas mix. This combination also produces less spatter than CO2 so there is less post-weld cleanup. Use 100 percent CO2 shielding gas or a 75 percent CO2/25 percent argon mix in combination with a carbon steel solid wire. Aluminum welding wire requires argon shielding gas, while stainless steel wire works best with a tri-mix of helium, argon and CO2. Always reference the wire’s spec sheet for recommendations. For all positions, it is best to keep the welding wire directed toward the leading edge of the weld puddle. If you are welding out of position (vertical, horizontal or overhead), keeping the weld puddle small provides the best control. Also use the smallest wire diameter that will still fill the weld joint sufficiently. You can gauge heat input and travel speed by the weld bead produced and adjust accordingly to gain better control and better results. For example, if you produce a weld bead that is too tall and skinny, it indicates that the heat input is too low and/or your travel speed is too fast. A flat, wide bead suggests too high of heat input and/or too slow of travel speeds. Adjust your parameters and technique accordingly to achieve the ideal weld, which has a slight crown that just touches the metal around it. These answers to frequently asked questions only touch on a few of the best practices for MIG welding. Always follow your welding procedures to gain optimal results. Also, many welding equipment and wire manufacturers have technical support numbers to contact with questions. They can serve as an excellent resource for you.

Is your robotic welding operation costing time and money for problems like burnbacks, premature contact tip wear, loss of tool center point (TCP) or other issues? These common failures in robotic welding can be costly, resulting in downtime and unplanned part replacement. Even issues that seem minor, such as the wire sticking to the contact tip and forcing tip replacement, can cost thousands of dollars per day when you consider lost consumables, cell downtime and labor costs for changeover. Beyond the time and money spent on minor issues, there’s also the risk of catastrophic failure that could short out the robot or damage system electronics — potentially costing tens of thousands of dollars. Avoiding common failures is often a matter of proper weld cell setup and robot maintenance, in addition to following some best practices for consumable installation. Operator training is also critical in preventing common failures in robotic welding. One of the most common failures in a robotic weld cell is burnback and premature contact tip wear. The top cause of burnback is an improperly trimmed gun liner. When a liner is too short, it won’t seat in the retaining head properly, causing burnback. To avoid this problem, follow the manufacturer’s recommendations for proper liner trimming. It’s also helpful to choose a high-quality liner designed for accurate liner trimming and installation. Burnback is one cause of premature contact tip wear, but wear can also result from other factors. Using low-quality wire with a lot of cast can be another cause, as it quickly wears out the contact tip compared to using a better-quality, straighter wire. Drive rolls that are too tight can also cause wire cast issues that wear the contact tip faster. Improper welding parameters — such as welding too hot or too cold — can also wear contact tips prematurely and force more frequent changeout. Adjust parameters accordingly to minimize this problem. The main cause of broken cutter blades in robotic welding is incorrect positioning or too much angle of the robotic MIG gun nozzle as it enters the reamer for cleaning. For example, if the depth of the Z axis is too deep, the torch will go in too far and may cause the reamer blades to break. To prevent this, the nozzle should be concentric to the cutting blade. Use an angle finder app on your smartphone or tablet to ensure the positioning is straight up and down on the X and Y positions. Also, be sure the insertion depth on the nozzle goes past the gas holes on the diffuser. Drag marks on the diffuser or contact tip are signs of wear that mean the nozzle is not concentric to the reamer blade. Proper setup and positioning also helps ensure consistent coverage of anti-spatter spray on the nozzle. Broken cutter blades can also result from excessive spatter in the nozzle, which can be caused by poor spraying setup, incorrect weld parameters or incorrect torch angle. Spatter sticks to spatter and as the buildup grows, it can break the cutter blade as it tries to enter the nozzle. Keep in mind that you may need to ream and spray more frequently depending on the application and the material being welded to avoid some of these issues. Problems with the contact tip, nozzle, reamer and excessive spatter can also result when there is poor grounding in the weld cell. Regularly inspect all cables for damage and be sure the ground cables are securely connected. When TCP is lost in a robotic weld cell, one common cause is improperly installed consumables. A cross-threaded consumable will angle the contact tip where it meets the retaining head, causing the tip to bend and disrupting TCP. Be sure to tighten consumables to the manufacturer’s torque specifications. The general rule of thumb is one quarter turn past finger tight. A worn clutch can also cause loss of TCP. The clutch system helps prevent damage to the robot or gooseneck during tooling collisions. After repeated incidents, the clutch may allow a few degrees of movement in either direction, which throws off TCP. Consider using a neck inspection fixture, which tests and adjusts the tolerance of a robotic MIG gun’s neck to the TCP so you can readjust it after an impact or after bending due to routine maintenance. In a robotic weld cell, the disc functions as a buffer between the mount and the robot arm. It’s designed to be sacrificial; if the torch, mount or robot arm collide, the disc will absorb the bulk of the impact. However, the disc can be broken when it’s hit hard enough by the neck or torch mount, so replace it if damaged. Set the robot path correctly to avoid neck collisions. Overtightening the screws can also break or crack the disc and cause it to fail. Discs have torque specifications from the manufacturer. Use those specifications to prevent overtightening and reduce the risk of cracking. The specification sheet also describes the order in which the screws on the disc should be tightened. Robotic weld cell failures can also be caused by programming errors. If the robot’s path to the tooling is programmed incorrectly, the arm can come into contact with the tooling or the weld cell wall. The torch rubbing on the cell wall can create holes in the cable. In addition, if the neck frequently hits the tooling, this can bend the neck or cause the disc to break. To prevent these issues, program the robot so the arm is clear of the tooling and doesn’t encounter the tooling or the wall. Preventive maintenance is key to keeping a robotic welding system and its components performing optimally — and extending consumable life. Regularly check all cables to make sure they are secure, free of damage and not rubbing anything. Establish and follow a schedule for liner changeover. The required frequency of liner changeover depends on what type of filler metal is being used, what material is being welded and shop conditions. A shop that is very dusty means liners will clog faster, for example. Consult the manufacturer’s maintenance recommendations and follow a preventive maintenance checklist to ensure all the system’s components and parts remain in good working order. Using high-quality robotic MIG guns and consumables also helps prevent problems that can arise in the weld cell. Taking steps to avoid common failures in the robotic weld cell allows your operation to improve productivity, reduce consumable costs and ensure consistent part quality.