Considerations for Consumables in Robotic Welding Applications

Investing in a robotic welding system goes beyond the initial purchase — it is equally important to find ways to maximize the abilities of this equipment. When implemented properly, speed, accuracy and cost savings are fundamental benefits of welding automation. These factors rely on everything from the robot itself to personnel overseeing the weld cell to the smallest factors, like the front-end consumables on the robotic MIG gun.

Although consumables may seem insignificant, the nozzles, contact tips and gas diffusers can have a huge impact on performance. The right combination reduces downtime and waste, and improves productivity and quality. In fact, a contact tip often serves as a barometer of the overall effectiveness of the welding process, by indicating how optimized it is — or isn’t.

Always consider consumables as a part of the planning process when working with an integrator to design a robotic welding system. Doing so prevents issues with joint access — if the consumables are an afterthought, it’s possible that the front-end of the robotic MIG gun won’t be able to maneuver properly around the part or the fixturing to reach the joint. Reconfiguring the system can be time-consuming and costly.

Space and duty cycle factors

Bottleneck, straight or tapered nozzles can help accommodate for joint restrictions since they are narrower than standard nozzles and provide better access. Take caution when using tapered nozzles, however, as they are thinner and may not be able to withstand the higher amperage or higher-duty-cycles of robotic welding, leading to more frequent changeover. They may also collect more spatter buildup due to their narrower bore.

For jobs requiring 300 amps or greater and/or those with a high level of arc-on time, a heavy-duty style nozzle with thicker walls and insulators will be more heat-resistant. It’s usually best to select the heaviest duty consumable for the application that still allows access to the tooling. Consult a robotic integrator or welding distributor whenever in doubt.

Consumable materials and sizes

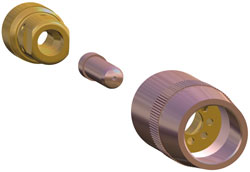

Consumables come in a variety of materials and sizes. For example, heavy-duty contact tips are available in copper or chrome zirconium and feature an outside diameter (OD) of around 0.3125 inch. In addition to pulsed welding (discussed more later), higher-amperage applications can benefit from chrome zirconium contact tips, as they generally offer a longer performance life than copper contact tips.

Nozzles are typically available in brass or copper. The brass variety tends to be more spatter-resistant. However, these nozzles have a lower melting point and can fracture or deteriorate more quickly than copper, if they come into direct contact with the molten weld pool. This factor makes them ill-suited for tight access applications.

Extra-heavy-duty consumables are also available in the marketplace and are good for high-amperage applications requiring larger-diameter welding wires — 0.052 inch and greater. Contact tips in this category generally have an outer diameter of about 0.375 in.

Regardless of the material, look for consumables that are well-machined with a smooth, consistent surface. These are less prone to spatter buildup and may therefore last longer. In some cases, these consumables may be more expensive, but it’s important to weigh the upfront costs with the longer-term savings of minimizing changeovers and downtime. Likewise, poorly functioning consumables, or ones that are simply not appropriate for the application, can generate weld quality issues that compound productivity delays and could lead to expensive rework.

good defense against premature consumable

failure and poor shielding gas coverage,

and can help extend the life of front-end

consumables.

Heavy- versus standard-duty

Robotic welding systems typically operate for longer periods of time at higher amperages than semi-automatic applications. As mentioned, heavy-duty consumables, which are more heat-resistant than standard-duty consumables, are often used. But they aren’t always necessary. In some cases, standard-duty consumables can replace them. For example, in applications with low duty cycles, there is less heat because less time is spent welding, and standard-duty consumable will suffice. It is important, however, to test for durability on a given application before introducing them into the welding operation.

Also, when frequent consumable changeover is part of a company’s protocol, standard-duty consumables could work on high-amperage applications because the welding operator changes them over before a failure occurs from high heat levels.

Welding mode and wear

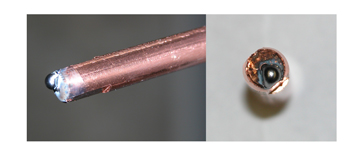

Mechanical wear on the contact tip is inevitable in any welding application, as the constant friction of the welding wire feeding through the tip naturally wears on it. But electrical wear also can be an issue in high-amperage welding that uses a pulsed welding mode.

Pulsed welding programs have a unique waveform that causes the power source to move between low background currents and high peaks, which is particularly harsh on consumables. Often these waveforms reduce weld spatter but are harder, electrically speaking, on the contact tip. It is important to select contact tips that are durable enough for the application, and often chrome zirconium contact tips are the best choice for this welding mode.

It is also a good idea to monitor contact tip usage regularly in pulsed welding applications. Changing over contact tips before they are too damaged can help to prevent issues such as loss of electrical conductivity, burnbacks and excessive spatter, resulting in poor weld quality, rework and downtime. Welding operators can use the time during routine breaks in production to changeover contact tips and maximize efficiencies.

Consider the impact of welding wire

Robotic welding often uses large drums of wires — 500 to 1,000 pounds — to minimize changeover. The wire in these drums tends to have less cast or helix than wire that feeds off of a smaller spool and, as a result, feeds through the contact tip in a relatively straight fashion, making little or no contact with the tip. This action minimizes the electrical conductivity necessary to create a good arc and a sound weld. It also can cause the welding wire to contact the part being welded and arc back into the contact tip, creating a burnback. This condition automatically creates downtime because the contact tip needs to be changed.

Undersizing contact tips, particularly when using solid wire in a high-amperage application, is a good fix. For example, a 0.040-in.-diameter contact tip could work for a 0.045-in. wire. The welding operator should check with a trusted welding distributor for applications requiring metal-cored wires because undersizing is not always an option.

It’s worth considering the impact that the wire type has on the longevity of the contact tips as well. Non-copper-coated solid wires, for example, tend to wear contact tips more quickly than copper-coated ones because the coating acts like a lubricant to improve feedability. Improved feedability can, in turn, lead to longer contact tip life.

Maintaining Consumables

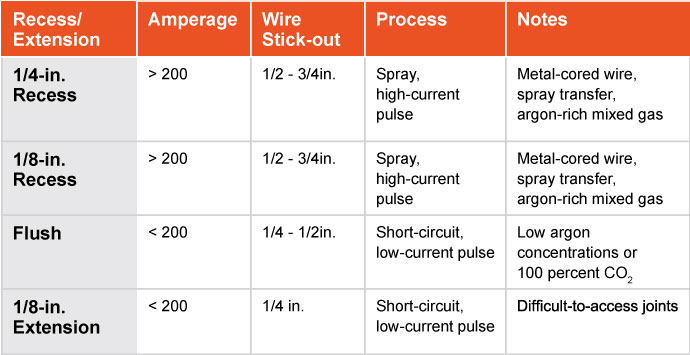

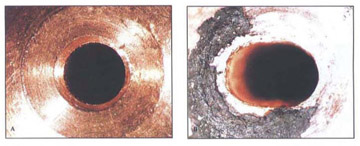

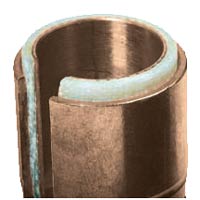

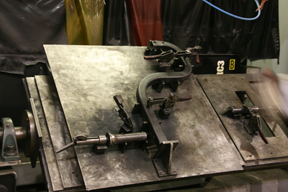

A nozzle cleaning station or reamer cleans spatter from the robotic gun nozzle and clears away debris in the gas diffuser that accumulates during the welding process. Reamers can be outfitted with a sprayer that applies a water-based anti-spatter compound to protect the nozzle, retaining head and workpiece from spatter. Reamers and anti-spatter combined are a good defense against premature consumable failure and poor shielding gas coverage (caused by spatter-blocked gas ports), and can help extend the life of front-end consumables.

For the best results, place the nozzle cleaning station close to the robot so it’s easily accessible, and program the robot to use it in between cycles — during part loading or tool transfer, for example. It should only take six seconds for the nozzle cleaning station to complete its job and the results are measurable: less spatter and longer consumable life.

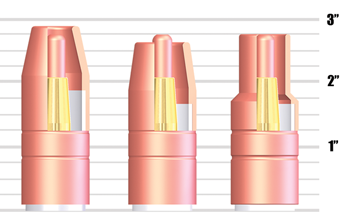

Although MIG gun consumables may seem like small part in the welding process, they can have a big impact. In fact, how well a welding operator selects and maintains these consumables can determine how productive and effective the welding operation is — and how long the consumables last. Below are a few best practices that every welding operator should know when it comes to choosing and maintaining nozzles, contact tips, retaining heads and gas diffusers, and cable. Because nozzles direct the shielding gas to the weld pool to protect it from atmospheric contamination, it is critical that gas flow is unobstructed. Nozzles should be cleaned as often as possible — at least every other welding cycle in a robotic welding operation — to prevent spatter buildup can lead to poor gas shielding or cause short-circuiting between the contact tip and nozzle. Always ream nozzles and remove all spatter with the proper designed cutting blade to prevent damage to the nozzle and to avoid permanently altering it. Even when using a reamer or nozzle cleaning station, periodically inspect the nozzle for spatter adhesion, blocked gas ports and carburized contact surfaces before and after each use. Doing so is added protection to prevent poor gas flow that could affect weld quality. Often, if spatter adheres to a nozzle, it means that nozzle’s life is over. Consider using a quick spray of anti-spatter solution at least every other reaming session. When using this liquid in conjunction with a reamer, be careful that the sprayer never sprays the insert, because the solution will deteriorate the ceramic compound or fiberglass inside the nozzle. For high-temperature robotic welding applications, heavy-duty consumables are recommended. Keep in mind that, while brass nozzles often collect less spatter, they are also less heat resistant than copper. However, spatter more readily adheres to copper nozzles. Choose your nozzle compound according to the application — decide whether it’s more efficient to frequently change over bronze nozzles that burn out faster or consistently ream copper nozzles that last longer but collect more spatter. Typically a contact tip wears out in one area or on one side first, depending on the welding cycle and how tight the| wire is. Using contact tips that can be rotated within the gas diffuser (or retaining head) can help extend the life of this consumable —and possibly even double its service life. Always inspect contact tips and gas diffusers before and after each use to ensure all of the connections are in place and snug. When using an anti-spatter liquid, periodically check gas ports in the gas diffuser for blockage, and regularly inspect and replace the O-rings and metal retaining rings that hold the nozzle in place. Old rings can cause nozzles to fall down or shift positions at the point of connection to the gas diffuser. Next, be sure all of the parts match. For example, when using a coarse threaded contact tip, make sure it is paired with a threaded diffuser that matches. If the robotic welding operation calls for a heavy-duty retaining head, be sure to pair it with heavy-duty contact tips. Lastly, always select the proper diameter contact tip for the wire being used. Note, that some mild steel or stainless steel wire might call for a contact tip with a smaller inside diameter as compared to the wire size. Never hesitate to consult tech support or a sales person to determine which contact tip and gas diffuser combination will best suit the application. Always check the torques of the body tube and end fittings regularly, as loose fitting cables can cause overheating and lead the robotic MIG gun to prematurely fail. Likewise, periodically check all cables and ground connections. Avoid rough surfaces and sharp edges that can cause tears and nicks in the cable jacket; these can also cause the gun to prematurely fail. Never bend cables more than suggested by the manufacturer. In fact, sharp bends and loops in the cable should always be avoided. Often the best solution is to suspend the wire feeder from a boom or trolley, thereby eliminating a large number of bends and keeping the cable clear of hot weldments or other hazards that could lead to cuts or bends. Also, never immerse the liner in cleaning solvents because it will corrode the cable and outer jacket, reducing the life expectancy of both. But do periodically blow it out with compressed air. Finally use anti-seize on all threaded connections to ensure electricity transmission flows smoothly and everything all connections remain tight. Remember, by selecting complementary consumable components and taking good care of them, it is not only possible maximize the efficiency and productivity of the robotic welding operation, but also it is possible to reduce downtime and increase profits. In many cases, MIG gun consumables may be an afterthought in the welding process, as concerns with equipment, workflow, part design and more dominate the attention of welding operators, supervisors and others involved in the operation. Yet, these components — particularly contact tips — can have a significant impact on welding performance. In a MIG welding process, the contact tip is responsible for transferring the welding current to the wire as it passes through the bore, creating the arc. Optimally, the wire should feed through with minimal resistance while still maintaining electrical contact. The position of the contact tip within the nozzle, referred to as the contact tip recess, is just as important. It can influence quality, productivity and costs in the welding operation. It can also affect the amount of time spent performing non-value-added activities, such as grinding or blasting parts that do not contribute to the operation’s overall throughput or profitability. Contact tip recess affects a number of factors that in turn can influence weld quality. For example, stickout or electrode extension (the length of the wire between the end of the contact tip and the work surface) varies according to contact tip recess — specifically, the greater the contact tip recess, the longer the wire stickout. As the wire stickout increases, voltage increases and amperage decreases. When this occurs, the arc may destabilize, causing excessive spatter, arc wander, poor heat control on thin metals and slower travel speeds. Contact tip recess also affects radiant heat from the welding arc. Heat buildup leads to an increase in electrical resistance in the front-end consumables, which reduces the contact tip’s ability to pass the current along to the wire. This poor conductivity can cause insufficient penetration, spatter and other problems that could result in an unacceptable weld or lead to rework. Also, too much heat generally reduces the working life of the contact tip. The result is higher overall consumable costs and greater downtime for contact tip changeover. Because labor is almost always the greatest cost in a welding operation, that downtime can add up to unnecessary increases in production costs. Another important factor impacted by contact tip recess is shielding gas coverage. When the contact tip’s recess positions the nozzle farther away from the arc and weld puddle, the welding area is more susceptible to airflow that can disturb or displace shielding gas. Poor shielding gas coverage leads to porosity, spatter and insufficient penetration. For all of these reasons, it’s important to utilize the correct contact recess for the application. Some recommendations follow. The diffuser, the tip and the nozzle are the three primary parts that comprise MIG gun consumables. The diffuser attaches directly to the gun neck and carries current through to the contact tip and directs the gas into the nozzle. The tip connects with the diffuser and transfers the current to the wire as it guides it through the nozzle and to the weld puddle. The nozzle attaches to the diffuser and serves to keep the shielding gas focused on the welding arc and puddle. Each component plays a critical role in overall weld quality. Two types of contact tip recess are available with MIG gun consumables: fixed or adjustable. Because an adjustable contact tip recess can be changed to varying ranges of depth and extensions, they have the advantage of being able to meet the recess demands of different applications and processes. However, they also increase the potential for human error, since welding operators adjust them by maneuvering the position of the nozzle or via a locking mechanism that secures the contact tip at a given recess. To prevent variations, some companies prefer fixed-recess tips as a way to ensure weld uniformity and achieve consistent results from one welding operator to the next. Fixed recess tips are commonplace in automated welding applications where a consistent tip location is critical. Different manufacturers make consumables to accommodate a variety of contact tip recess depths, which typically range from a 1⁄4-inch recess to a 1⁄8-inch extension. The correct contact tip recess varies according to the application. A good rule to consider is under most conditions, as the current increases, the recess should also increase. Also because less wire stickout typically results in a more stable arc and better low-voltage penetration, the best wire stickout length is generally the shortest one allowable for the application. Here are some guidelines, below. Also, see Figure 1 for additional notes. These considerations can help with the choice, but always consult the manufacturer’s recommendations to determine the right contact tip recess for the job. Remember, the correct position can reduce the opportunity for excessive spatter, porosity, insufficient penetration, burn-through or warping on thinner materials, and more. Moreover, when a company recognizes contact tip recess as the culprit of such problems, it can help eliminate time-consuming and costly troubleshooting or post-weld activities such as rework. Because contact tips are an important factor in completing quality welds and reducing downtime, it’s important to select a high-quality contact tip. While these products may cost slightly more than lesser-grade products, they offer long-term value by extending life spans and reducing downtime for changeover. In addition, higher-quality contact tips may be made from improved copper alloys and are typically machined to tighter mechanical tolerances, creating a better thermal and electrical connection to minimize heat buildup and electrical resistance. Higher-quality consumables typically feature a smoother center bore, resulting in less friction as the wire feeds through. That means consistent wire feeding with less drag, and fewer potential quality issues. Higher-quality contact tips can also help minimize burnbacks and help prevent an erratic arc caused by inconsistent electrical conductivity. Select from Bernard consumables systems

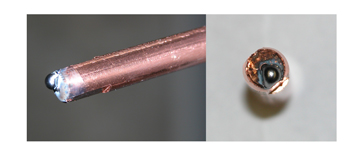

While only one part of a much larger system, the contact tip in both robotic and semi-automatic welding MIG guns plays a critical role in providing sound weld quality. It can also factor measurably into the productivity and profitability of a welding operation — downtime for excessive changeover can be detrimental to throughput, and the cost for labor and inventory. The major functions of a contact tip are to guide the welding wire and transfer the welding current to the wire as it passes through the bore. The goal is to have the wire feed through the contact tip smoothly, while maintaining maximum contact. To get the best results, it is important to have the right contact tip size —or inner diameter (ID) — for the application. The welding wire and welding process both influence the selection.

Selecting equipment to provide the highest quality and productivity in a welding operation goes beyond just the power source or welding gun — consumables play an important role, as well. Contact tips, in particular, can make a significant difference between running an efficient process and accruing downtime to rectify problems. Selecting the right contact tip for the job can also impact the profitability of the welding operation. Contact tips are responsible for transferring the welding current to the wire as it passes through to create the arc. Optimally, the wire should feed through with minimal resistance, while still maintaining electrical contact. For that reason, it is always important to select a high-quality contact tip. While these products may cost slightly more than lesser-grade products, there is long-term value to negate that upfront purchase price. Namely, higher-quality contact tips are typically machined to tighter mechanical tolerances, creating a better thermal and electrical connection. They may also feature a smoother center bore, resulting in less friction as the wire feeds through. That means consistent wire feeding with less drag, which eliminates potential quality issues. Higher-quality contact tips can also help minimize burnbacks (the formation of a weld inside the contact tip) and help prevent an erratic arc caused by inconsistent electrical conductivity. They also tend to last longer. Contact tips used for semi-automatic MIG welding are typically composed of copper. This material provides good thermal and electrical conductivity to allow consistent current transfer to the wire, while also being durable enough to withstand the heat generated during the welding process. For robotic welding, some companies choose to use heavier-duty chrome zirconium contact tips, as these are harder than copper ones and better withstand the increased arc-on time of an automated application. In most cases, using a contact tip that matches the size of the wire leads to the best results. However, when wire is fed from a drum (e.g. those 500 pounds and larger) and/or when using solid wire, an undersized contact tip may improve welding performance. Because wire from a drum tends to have less cast, it feeds through the contact tip with less or no contact — having a smaller bore exerts more pressure on the wire, creating greater electric conductivity. Undersizing a contact tip, however, can increase friction, resulting in erratic wire feeding and, potentially, burnback. Conversely, using an oversized tip can decrease current transfer and increase tip temperatures, which can also lead to wire burnback. When in doubt about selecting the proper size contact tip, consult a trusted consumable manufacturer or welding distributor. As a best practice, always check the connection between the contact tip and the gas diffuser to be certain it is secure — a secure connection reduces electrical resistance that could lead to overheating. Contact tip recess refers to the position of the contact tip within the nozzle and is an important factor influencing weld quality, productivity and costs in a welding operation. Specifically, correct contact tip recess can reduce the opportunity for excessive spatter, porosity and burnthrough or warping on thinner materials. It can also help minimize radiant heat that could cause premature contact tip failure. Contact tip recess directly impacts wire stickout, also called electrode extension. The greater the recess, the longer the stickout is and the higher the voltage, which can make the arc slightly less stable. For that reason, the best wire stickout is generally the shortest one allowable for the application; it provides a more stable arc and better low-voltage penetration. Typical contact tip positions are 1/4-inch recess, 1/8-inch recess, flush and 1/8-inch extension. Refer to Figure 1 for recommended applications for each. Contact tip failure can result from a number of influences, including burnbacks, mechanical and electrical wear, poor welding operator technique (e.g., variations in gun angle and contact-tip-to-work-distance [CTWD]) and reflective heat from the base material, which is common in tighter access weld joints or confined areas. The quality of the wire being used can also affect contact tip life. Poor quality wire often has an undesirable cast or helix that can cause it to feed erratically. That can prevent the wire and contact tip from connecting properly through the bore, resulting in low conductivity and high electrical resistance. These issues can lead to premature contact tip failure due to overheating, as well as poor arc quality. To extend contact tip life, consider the following: In some instances, it may be desirable to convert to a water-cooled MIG gun to help keep the front-end consumables, including the contact tip, cooler and running for longer. Companies should also consider tracking their contact tip usage, noting excessive changeover and addressing accordingly with some of the suggested precautions. Addressing this downtime sooner than later can go far in helping companies reduce unnecessary costs for inventory, while also improving quality and productivity.

Premature contact tip failure is a common problem that can lead to unexpected downtime — and added costs — in a welding operation. This issue not only hinders productivity, it can also negatively affect weld quality and create rework. Contact tips play a critical part in achieving high quality welds. Because of the constant friction from the wire and the exposure to the heat of the arc (and, in some cases, the reflective heat from the base material), contact tips take a tremendous amount of abuse during welding. This can easily turn into premature contact tip failure without the proper precautions. Understanding the typical types of contact tip failures and their causes is the best approach to preventing them. There are two main types of contact tip failure. 1. Failure that leads to a burnback and its associated problems 2. Failure that produces contact tip wear Burnbacks occur when a weld forms within the contact tip and can occur at any point along the weld. They are not necessarily the result of poor contact tip performance, but rather burnbacks can result from too slow of wire feed speeds and/or incorrect contact-tip-to-work distance (also referred to as CTWD). The CTWD is the distance between the end of the contact tip and the base material; if the distance is too short (i.e. the contact tip is too close to the workpiece), a burnback can occur. The quality of the wire, incorrect parameter settings and micro-spatter buildup, as well as incorrect wire feeder and liner adjustments can all contribute to burnbacks. When they occur, burnbacks reveal themselves by way of poor arc starts, arc instability, inconsistent wire feeding and, ultimately, stoppages in wire feeding altogether. Contact tip wear can be both mechanical and electrical. It occurs from the friction of the wire feeding through the bore of the contact tip and is especially prevalent in higher amperage semi-automatic and robotic applications. In the latter, contact tip wear can produce issues with tool center point (TCP), resulting in offset welds and potentially rework, especially in robotic welding systems that do not employ seam tracking. The design of the contact tip and the material it is composed of are two factors that affect a contact tip’s tendency toward wear. Typically, manufacturers use copper for contact tips because it is readily available and offers good electrical and thermal conductivity. Copper, however, has a relatively low resistance to wear, making it more prone to failures. For higher amperage applications, companies often turn to chrome zirconium contact tips due to their strength and their ability to resist wear by heat. All contact tips, regardless of the material used to manufacture them, will eventually fail if used or abused for a long enough periods of time and/or at a high enough temperature. They are, after all, consumables with a finite lifespan. The goal, nonetheless, is to prolong the life of the consumables in order to avoid unnecessary downtime, as well as cost for additional inventory. A good step in achieving those goals is to understand the ways to help prevent contact tip failure. Burnbacks: There is no one solution to minimize contact tip failure due to burnbacks; each situation is unique and may require a series of corrective actions. The goal is to address the associated errors or issues that are leading to the burnback in the first place. The two key solutions for minimizing burnbacks include increasing the wire feed speed and/or lengthening the distance of the MIG gun from the workpiece. The nozzle should be no further than one-half inch from the base metal. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce CTWD variability. The wire’s cast is affected by three main factors: the supply reel (spool or drum); drive roll tension; and MIG gun neck angle. A tight wire cast may allow for a looser bore tolerances and still be able to make the appropriate electrical contact with the contact tip to create a stable arc. A straighter cast may require a contact tip with a tighter bore to exert pressure on the wire and create consistent conductivity. It is important to note that with a smaller contact tip bore, there is a risk of the spatter build up, so cleanliness is key. Selecting contact tips with a smooth surface and bore can also help prevent the wire from snagging on the consumable and causing a burnback. Using a contact tip/gas diffuser design that maximizes the surface area between these consumables is another option to reduce the potential for this problem — the tight connection creates less heat and can reduce micro-spatter that could hinder the wire from feeding and becoming blocked in the contact tip bore. Additional preventive measures include: • Adjusting the drive rolls to ensure smooth wire feeding Contact tip wear: The degree of wear on a contact tip depends on multiple factors, including operating temperatures; the wire cast; and the surface condition, material properties and bore tolerances of the contact tip. Lowering operating temperatures, when feasible, is among the best defenses against contact tip wear. These lower temperatures can be achieved in a number of ways, for example, using a water-cooled MIG gun. These types of guns are especially well suited for higher amperage applications (usually between 300- and 600-amps). They do, however, introduce some additional complexities to the welding operation that companies need to consider. Namely, water-cooled guns have a weaker neck than air-cooled models, so in robotic applications specifically, they can be more prone to bending in the event of a crash. They also tend to be more expensive to maintain. When deciding whether to use a water-cooled MIG gun to help combat the excessive heat that could lead to contact tip wear, users will have to weigh out the advantages and disadvantages of this equipment in terms of costs and productivity to determine if the product is the best choice. An alternative to reduce contact tip wear via lower temperatures would be to use a thermally-effective air-cooled torch in combination with front end consumables designed to dissipate heat. Typically, high quality consumables have been designed to seat firmly together to minimize electrical resistance, thereby generating less heat and reducing the opportunity for contact tip wear and failure. Remember that cheaper isn’t always better. When it comes to purchasing consumables, it may be worth the extra cost upfront for such a design in order to minimize long-term costs and downtime associated with contact tip changeover. In any welding operation, there is no single solution to instill efficiencies — it can be a matter of technique, equipment and more. However, minimizing contact tip failure is an important way to reduce downtime and costs, while also ensuring higher weld quality. Be sure to train new welding operators as to the value of taking preventive measures to combat burnbacks and contact tip wear, emphasizing the impact of these occurrences on the overall welding operation. As with any process, education can go a long way in helping companies create a more productive and profitable business.

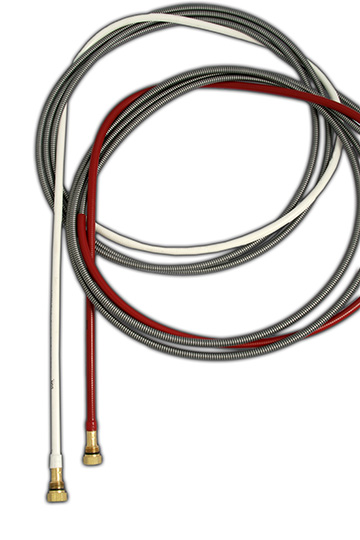

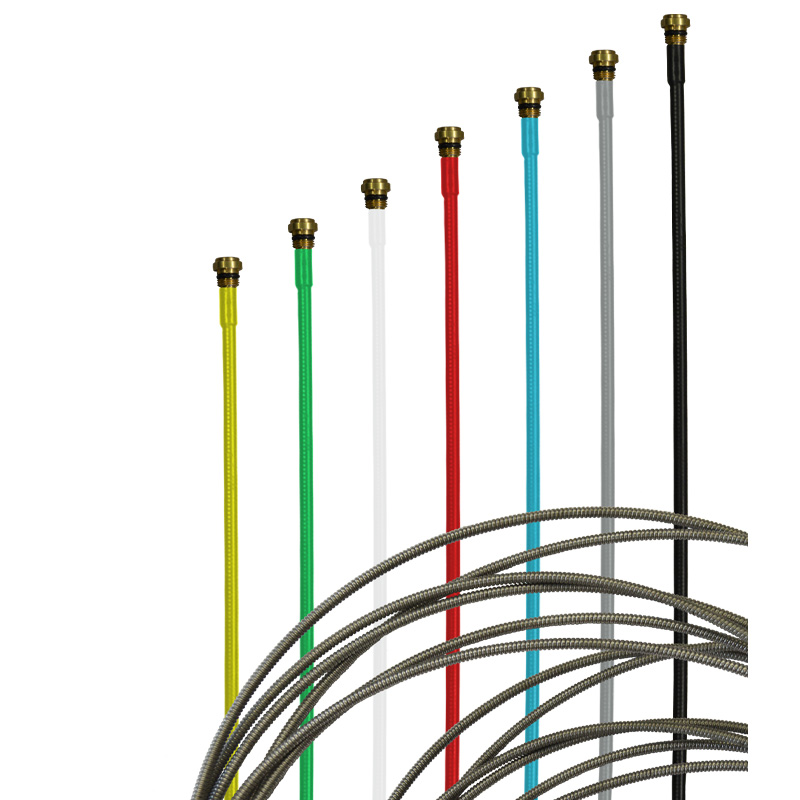

MIG gun consumables, including the liner, can make significant difference in gun performance and weld quality. A MIG gun liner spans from the front of the gun through to the power pin and is the conduit through which the welding wire feeds. Proper installation of the liner is critical to its ability to guide the wire through the welding cable and up to the contact tip — and to help an operation avoid the many problems that can result from improper liner installation, such as birdnesting, wire feeding issues and increased debris in the liner. There are numerous liner types available that are usable for both semi-automatic and robotic applications. Choosing one is often up to the preference of the welding operator or maintenance personnel. Each type has advantages and disadvantages for specific applications in robotic and semi-automatic welding and can offer compatibility with varying gun styles and sizes. The three main categories of liner types are conventional liners, front-loading liners and front-loading liners that have a spring-loaded module to accommodate for up to 1 inch of forgiveness for improperly trimmed liners. Conventional liners are installed through the back of the gun and are longer than the cable, often up to 25 feet long. These are frequently used in the industry; so many welding operators are familiar and comfortable installing this type of liner. A disadvantage of conventional liners is the lengthy changeover process. In the cases of liner replacement, this may require the welding operator to climb over robotic tooling or transfer systems to remove the gun from the wire feeder. In the case of semi-automatic MIG guns that are connected to boom-mounted feeders, the welding operator may need to climb several feet into the air to change liners. Another disadvantage of conventional liners is that they can’t account for changes in length as the cable grows and shrinks with twisting (due to the fact that MIG gun cables are wound in a helix pattern). This can lead to the liner not being seated properly inside the retaining head. Front-loading liners are, as the name implies, installed from the front of the gun. This offers timesaving advantages, since the welding operator does not have to leave the front of the gun for changeover, which can reduce downtime. Front-loading liners have the same disadvantage as conventional liners, since they can’t grow or shrink with the cable as it twists and moves. Jump liners are a type of front-loading liner-. Whereas standard front-loading liners are full length, jump liners are shorter — often about 1 foot long — and replace only the part of the liner that wears the quickest, typically at the neck of the gun. The third main category is front-loading liners that have a spring-loaded module inserted into the power pin, allowing for up to 1 inch of motion as the cable twists and springs up and down. This type of liner tends to be more forgiving if the liner is trimmed incorrectly. Choosing the right type of liner for the application can help an operation avoid feeding issues and reduce downtime. While welders may have a preference on liner type, be aware that each type of liner has advantages and disadvantages for specific applications and can offer compatibility with varying gun styles and sizes.

MIG gun consumables are often one of the most overlooked portions of the welding operation. However, choosing the right consumables, and using and maintaining them properly can make a significant difference in gun performance and weld quality. Consumables comprise the front-end part of the gun and include the nozzle, retaining head, contact tip and liner. A MIG gun liner spans from the front of the gun through to the power pin and is the conduit through which the welding wire feeds. Proper installation of the liner is critical to its ability to guide the wire through the welding cable and up to the contact tip. Improper liner installation — which includes trimming the liner too short or having a liner that is too long — can lead to a number of problems, such as birdnesting, wire feeding issues and increased debris in the liner. These issues can result in costly rework and operator downtime for maintenance and repairs, which impacts productivity. Also, wasted wire due to issues like birdnesting can drive up costs for a company. There are several liner types available for semi-automatic applications. Choosing one is often up to the preference of the welding operator or maintenance personnel. Each type has advantages and disadvantages for specific applications and can offer compatibility with varying gun styles and sizes. Conventional liners are installed through the back of the gun and are longer than the cable, often up to 25 feet long. These are frequently used in the industry; so many welding operators are familiar and comfortable installing this type of liner. A disadvantage of conventional liners is the lengthy changeover process. In the cases of liner replacement, this may require the welding operator to climb over robotic tooling or transfer systems to remove the gun from the wire feeder. In the case of semi-automatic MIG guns that are connected to boom-mounted feeders, the welding operator may need to climb several feet into the air to change liners. Another disadvantage of conventional liners is that they can’t account for changes in length as the cable grows and shrinks with twisting (due to the fact that MIG gun cables are wound in a helix pattern). This can lead to the liner not being seated properly inside the retaining head, resulting in wire chatter and feeding issues. Front-loading liners are, as the name implies, installed from the front of the gun. This offers timesaving advantages, since the welding operator does not have to leave the front of the gun for changeover, which can reduce downtime. Front-loading liners have the same disadvantage as conventional liners, since they can’t grow or shrink with the cable as it twists and moves. Jump liners are a type of front-loading liner. Whereas standard front-loading liners are full length, jump liners are shorter — often about 1 foot long — and replace only the part of the liner that wears the quickest, typically at the neck of the gun. Front-loading liners that have a spring-loaded module inserted into the power pin allow for up to 1 inch of motion as the cable twists and the liner moves forwards and backwards. This type of liner reduces the opportunity for gaps at the front of the gun and helps to compensate if the liner is trimmed too short. Systems like the Bernard® AccuLock™ S Consumables for semi-automatic MIG guns feature a nozzle, contact tip, diffuser and liner design that work in conjunction to provide error-proof liner installation and replacement. The AccuLock™ S Liner loads through the neck at the front of the gun, then is locked and concentrically aligned to both the contact tip and power pin. The liner is then trimmed flush with the power pin — no measuring required — and reinstalled to the wire feeder. This eliminates gaps and misalignments at the front and back of the MIG gun liner for flawless wire feeding. The installation process is somewhat similar for all three types of liners, with some variations. Here are some general steps to consider when installing a new MIG gun liner. These steps are the same for both semi-automatic and robotic MIG guns: 1. Before removing the consumables, make sure the gun is straight and the cable is flattened. This makes it easier to feed the liner all the way through. 2. Trim the wire at the front of the gun to remove the bead of molten wire that often forms after welding. 3. Remove all of the front-end consumables so the liner can be fed through the gun. 4. For a conventional liner installation, remove the power pin from the feeder at the back of the gun and cut the wire. This allows the wire and a conventional liner to be removed from the back of the gun. 5. If using a conventional liner, feed the liner through the back of the gun, threading it into the power pin. Reinsert the power pin back into the feeder, and feed a few inches of wire through the back of the power pin. That way, once all of the consumables are back on at the front of the gun, the wire is already in the gun and ready to be pulled through. (See below for variations for front-load liners and front-load liners with spring-loaded modules) 6. Because the liner is longer than the gun assembly (designed to accommodate varying gun and cable lengths), there will be a foot or so of liner sticking out the front of the gun, so it’s necessary to trim the liner to the correct length. Conventional liners and front-loading liners often come with a plastic liner gauge that has a 3/4-inch stick-out. This can be fed over the top of the liner and pressed up flush against the neck, so the liner can be trimmed to the end of the gauge. 7. Hit the trigger, to pull the wire up, and at the same time purge the gun with shielding gas. There are some variances in the installation process, depending on liner type. Here are some differences to note: • When installing a front-loading liner, unravel the liner (which comes coiled) and stick the brass end — the end that goes into the receiver at the back of the gun — over the wire and through the neck. Feed the liner through the front of the gun using short strokes, to avoid kinking the liner. The front-loading liner will click or snap into place once it hits the receiver in the power pin. Once that is complete, put the liner gauge on top of the liner and follow the standard installation steps above. • When installing a front-loading liner with the spring-loaded module, the only difference is that there is no receiver in the back of the power pin. The receiver is built into the module pin. While feeding the front-loading liner into the gun using short strokes, the liner will engage with the receiver inside of the module’s power pin. When this happens, the welding operator can feel the liner spring back toward the front of the gun. This is a good sign, because it means the liner is properly engaged. Place the liner trim gauge over the front-loading liner until it is flush against the neck. Push the liner back into the gun until it bottoms out against the spring-loaded module, then trim the liner flush to the end of the liner trim gauge. After trimming, remove the liner trim gauge and release the liner. Note that the liner will spring back and stick out of the neck by approximately 1-3/4 inch, which is normal, as installing the consumables will compress the liner into its proper position. The installation process also varies when retrofitting a gun from a conventional liner to a front-loading liner, or when completing a liner changeover, as compared to installing a new liner in a new gun. When it’s not the first time the liner is being installed, there are a few additional things to remember: • When retrofitting a gun from a conventional liner to a front-loading liner, the first installation will be from the back of the gun, since a receiver is needed on the back in order to accept the front-loading liner. • After following all of the standard steps above and removing the conventional liner and wire from the gun, install the end of the front-loading liner with the O-rings on it into the receiver and unravel the liner. Feed the front-loading liner in, just as with a conventional liner, through the back of the gun, and thread the receiver into the power pin. When installing a liner as part of the AccuLock S Consumables Series, follow the same steps as when installing other types of liners, removing the front-end consumables and old liner. Then replace the new liner through the neck, and with the gun lying straight, push the liner through until the brass liner lock bottoms in the neck. To lock and center the liner, reinstall the gas diffuser and nozzle, and place the power pin cap over the liner, torquing it to 60 in-lbs (7Nm). Then simply trim the liner flush with the power pin at the back — no need to measure the liner. The quality of the liner also can impact welding performance, productivity and operator downtime, so it’s important to buy quality liners from a trusted manufacturer. Choosing the correct size of liner for the wire being used is another way to help maximize performance. While liners may seem like a small part of the welding operation, it’s important to be mindful of the impact they can have on quality, performance and costs. Liners perform a vital function in the MIG welding process, and the proper installation and maintenance of liners can help reduce costly rework, operator downtime and wasted wire.

Welding is a tough business requiring equally tough equipment. When it comes to high amperage applications that is especially true. Applications exceeding 300 amps generate a large amount of reflective heat from the arc, making it necessary to have front-end consumables — nozzles, contact tips and gas diffusers — that can withstand the course of welding, whether it’s a semi-automatic or robotic application. Such applications are particularly common in industries such as heavy equipment manufacturing, where the material thicknesses are greater and therefore require the higher amperages to create quality welds. In some automotive applications that employ robotic welding systems, amperages can also fall into that same high level. The right consumables can help in high amperage applications in a number of ways.

Companies make the investment in welding automation with an eye toward the potential long-term benefits it can provide — better productivity, improved weld quality and reduced costs. Protecting that investment and realizing a quick return on it is as much a matter of planning as it is one of proper equipment selection and usage. That equipment includes everything from the largest components — the robot itself — to the smallest, including the front-end consumables on the robotic MIG gun. While seemingly insignificant, the nozzles, contact tips and gas diffusers used in robotic welding can have a marked effect on the overall performance of a robotic welding cell. Frequent changeovers can result in unnecessary downtime and costs. Poorly functioning consumables, or ones that are simply not appropriate for the application, can generate weld quality issues that compound productivity delays and could lead to expensive rework. Selecting the proper consumables and implementing some best practices for storage, installation and maintenance can help ensure the best results, increase product life and support the benefits sought in welding automation. Robotic welding systems typically operate for longer periods of time and at higher amperages than a semi-automatic application, and may utilize transfer modes that are especially harsh on consumables. For example, Pulsed MIG programs — those in which the power source “pulses” between low background currents and high peaks — tend to generate high levels of heat that can erode contact tips more quickly. For that reason, it’s important to select ones that are durable enough for the application. Contact tips are available in heavy and extended life heavy duty varieties composed of chrome zirconium, and are a good option for gaining longer performance due to their hardness (compared to copper). Typically, machined grooves at the base of the thread are the identifying mark for these types of contact tips. Selecting nozzles and contact tips that are well-machined with a smooth, consistent surface is key. Smooth surfaces are much less prone to collecting spatter, and therefore more likely to last longer. In some cases, these consumables may not be the least expensive option, but it’s important to weigh out the up-front costs versus the longer-term savings of minimizing changeovers and downtime. Space is always a consideration with robotic welding systems. Fixturing and tooling can limit the ability of the robot to maneuver to a part. Bottleneck, straight or tapered nozzles are common choices to accommodate for those restrictions since they are narrower than standard nozzles and can provide better access. The more tapered a nozzle, however, typically the thinner it is. As a result, it may be less able to withstand higher amperage or higher-duty-cycles commonly used in robotic welding applications. For jobs requiring 300 amps or greater and/or those that have a high level of arc-on time, it may be best to select a heavy-duty style nozzle. These have thicker walls and insulators and are more able to resist heat. In the end, a good rule of thumb is to select the heaviest duty consumable for the application that still allows access to the tooling in order to make it last the longest. If in doubt about the best choice, consult with a robotic integrator or welding distributor for a recommendation. Employing a nozzle cleaning station (also called a reamer) is a good defense against premature consumable failure and poor performance for many different styles of nozzles. A nozzle cleaning station cleans spatter out of the nozzle and clears away debris from the retaining head that tends to accumulate during the welding process. These stations can also be outfitted with a sprayer that applies a water-based anti-spatter compound to protect the nozzle, retaining head and workpiece from spatter after cleaning. For the best results, place the nozzle cleaning station close to the robot so it is easily accessible, and program the robot to use it in between cycles (during part loading or tool transfer, for example) so it doesn’t interrupt operation. It should only take 5-6 seconds for the nozzle cleaning station to complete its job and the results are measurable — less spatter and longer consumable life. As a best practice, keep consumables in their original packaging until they are ready for use. Opening them and placing them in a bin can lead to scratches or dents that allow spatter to adhere and will ultimately shorten the products’ life or cause them to function poorly. It can also cause dirt and oils to accumulate on the surfaces of the contact tip, which may impede them from properly seating together with the gas diffuser. It can also lead to electrical resistance and heat build-up issues that can, again, shorten their life span. Wear clean gloves when handling or replacing contact tips, nozzles and diffusers. It helps prevent dirt, oil or other contaminants from adhering to them and leading to premature failure or poor performance. ?Also, keep storage containers for new consumables separate from those for discarded ones to prevent the reuse of a contact tip or nozzle that may have dents or scratches and be prone to spatter accumulation. Good electrical conductivity helps ensure consistent arc performance and weld quality, and can help minimize excessive heat and extend the life of the consumables. Installing the consumables properly — according to the manufacturer’s suggestions — and periodically inspecting them for good connections is the best way to ensure that conductivity. Channel-lock pliers or other recommended installation tools work well to install contact tips and diffusers. Never use wire cutters or side cutters. Too much pressure from these tools can damage the inside diameter of the contact tip, and they can also cause scratches that attract spatter. A good rule of thumb is to hand-tighten the contact tip until it is fully seated into the diffuser. Next, grip the contact tip with an appropriate tool as close to the base as possible, tightening it one-quarter turn past finger tight. Follow the same procedure for installing and tightening the diffuser so that it fully connects with the neck. Some contact tips can be installed and held in place by hand-tightening the nozzle. Check the manufacturer’s recommendation for proper installation instructions. Finally, look for consumables that are designed to fully seat together and mate securely, too, as these can further increase their longevity by minimizing electrical resistance and heat build-up. As with any part of a robotic welding system, the goal is to keep consumables in the best working order so that the robot is able to continue doing its job. That, in turn, allows companies to spend more time reaping the benefits of the automated welding process and less time troubleshooting problems.

Consumables — contact tips, nozzles and gas diffusers (or retaining heads) — play an important role in the welding process and can impact productivity, costs and weld quality. Many factors influence the selection of consumables, including the application at hand, available budget and more. Some welding operations may view the purchase of consumables as a place to save money, since high-quality consumables typically cost more than lower-quality consumables. However, the up-front cost of consumables is just one part of the picture. Companies should consider the long-term benefits and savings that quality consumables can provide when making the selection, since consumables are an ongoing cost in the welding process. The optimal consumables are ones that provide the best quality and the longest life. These benefits in turn help lower replacement costs, minimize downtime and improve productivity. Also, quality consumables can often reduce post-weld cleanup work, saving time and money. The design, manufacturing process and materials are all characteristics that influence the performance of these components.

Anyone in a job shop environment knows how much downtime accrues from changing over a welding cell to accommodate different product runs. For Wisconsin-based OEM Fabricators, that downtime added up to $2,000 a day until it adopted the “rule of ones,” which standardized their welding processes, and implemented lean manufacturing concepts back in 2004. OEM is a job shop that specializes in fabricating components and assemblies for over 80 heavy equipment manufacturers across 20 industries, primarily the oil patch, oil exploration, power generation, and crane industries. Serving that many customers and meeting product runs from 1 to 250 units per run, welding operators at OEM had to regularly change welding processes, change wires, change gases and change other variables to accommodate each new product runs. The inefficiencies created by these changeovers, however, didn’t mesh well with the company’s philosophy. “Our goal is to be an extension of our customers,” explains Manufacturing Engineer Scott Exner. “We provide the services and products that they choose not to manufacture internally, so they need to be able to come to us and receive a quality product, on time, at a fair price.” That’s why the company adopted a “rule of ones” welding system — one process, one gas, one wire, one gun — as part of its implementation of lean manufacturing. With Bernard Q-Gun™ MIG guns and Centerfire™ consumables as an integral part of that implementation, OEM was able to reduce their downtime and expand their welding operation two to three times its size since implementing the welding process standardization approximately three years ago. OEM significantly reduced the potential for quality variance between welding operators and greatly reduced the time it took to do initial hiring training for it welders. OEM was not experiencing a manufacturing crisis when it began implementing lean manufacturing principles in 2004, but as a continuously forward-looking company, they saw the potential offered by becoming lean. “Integrating lean concepts in our operation has allowed us to look at all of our processes and how they’re interrelated,” Exner explains. “We might have as many as 20 people touching a product as it moves through the fabrication process. Lean principles help us provide our employees with the best information and the best tools to do their jobs as effectively as possible.” Providing their customers with a consistent and high quality product has been one of the foundations upon which OEM has built its reputation. One of the toughest parts of upholding that reputation has been establishing uniformity and consistency between their 115 welding operators while also reducing downtime and rework. Although it took only about 15 minutes for operators to change over from welding one product to another, the frequency of changeovers combined with the number of welding stations in the plant added up to a significant amount of time. “When you make that changeover in a multi-process mode,” explains Exner, “you have to change to a different wire, different gas, and then go through and re-setup your process parameters. All of that takes time and creates the possibility for inconsistency.” That’s when they began investigating the potential to standardize all of their welding operations on a single process, wire, gas, gun and consumables. The manufacturing flow and improvements and the savings that resulted are part of the reason OEM has been able to dramatically increase its size in a short period of time with two plants in full operation. For their process, OEM selected an advanced pulsed MIG process from Miller Electric Mfg. Co. that is able to monitor the arc and adapt the current thousands of times per second, allowing OEM’s welders to simply pull the trigger and weld while the power source ensures the correct output is produced. For the wire and gas, OEM selected a .045 ER70S-6 solid wire with a 90/10 Argon/CO2 mixed gas. The high argon content helps produce a very stable arc and allows the system to produce a spray transfer for high deposition and a calm weld puddle. When it came to selecting the one gun and consumables package that would handle nearly all of their manufacturing needs, OEM chose Bernard Q-Guns with Centerfire consumables. “When we first started integrating lean principles and standardization into our welding operations, guns and consumables were right at the top of our list,” Exner said. “We looked at a lot of different packages, but so far nothing has matched the Bernard Q300 gun and Centerfire consumables.” In fact, Exner said he still reviews competitive guns and consumables on a yearly basis, and he has yet to find a product that provides a better result for their applications. “We brought in guns from other manufacturers and sat down and wrote out a comparison listing what we liked and disliked about each gun,” Exner said. “There were some things we liked better on the other guns, but in the end, the Bernard Q300 was the whole package.” One of the biggest benefits Exner saw in the Q-Gun was its ability to be custom configured to meet the needs of a variety of different applications within their shop. Bernard’s 24-hour online Configurator allows customers to build a customized MIG gun by individually selecting each component, from the contact tip to the power pin, based on their specific needs. The Configurator can then be used to request a price quote from the company’s nearest welding distributor. “You can have different neck lengths, different bends and other options that allow it to fit into almost any position we need it to get into,” Exner said, noting that his operators especially like the rotatable neck, which allows them to access hard-to-reach joints and still be comfortable. Overcoming operator resistance to change is a constant concern in any manufacturing environment, particularly with regard to equipment that alters the ergonomic environment, such as a welding gun. However, the operators at OEM were surprisingly accepting of the Q-Gun. “I think I was more reluctant moving to the Q-Gun and Centerfire system than my welders were,” Exner said. “My guys loved the curved handles, the weight of the guns and the different neck configurations, so it was an easy choice for the people using the product to make the choice to go with Bernard.” Implementing lean practices resulted in more arc-on time for their operators, but because they were running their guns as high as 260 to 270 amps, Exner became concerned that they would exceed the duty cycle. To date, they have found that the Q300 has been able to handle all of their welding needs while still providing a comfortable weight and maneuverable size that they couldn’t find in a 400-amp gun. Another major factor in OEM’s decision to use Bernard MIG products was the Centerfire consumable system. “We don’t look at consumables as a big item in terms of cost,” Exner explained. “We look at consumables from a standardization stand point. We’re willing to pay a little more up front for the consumables if they are going to result in improved standardization, increased throughput, and reduced re-work on the back end, and that’s what Centerfire provides.” Featuring a fixed-recess, “drop-in” contact tip that sits in the diffuser and is held into place by a spatter guard in the nozzle, the Centerfire system provides OEM with consistent results regardless of who is behind the gun and a very calm gas flow that improves weld quality. Helping to establish uniformity between operators, the Centerfire’s fixed recess contact tip prevents the current and heat variances that occur when operators adjust their contact tips to different depths. “One of the biggest errors that welders tend to make is in setting the tip recess,” Exner said. “That plays a big role in how your arc is going to perform. Two different guys with the same tip recess are going to get more similar results than one guy using different tip recesses.’ Exner was also impressed by the gas flow provided by the built-in spatter guard. “One of the biggest benefits to the Centerfire system has been the gas flow,” Exner said. “The spatter guard provides a smooth, gentle flow from the nozzle, which does a better job of keeping out the air atmosphere. Other consumables create a turbulent gas flow that mixes with the atmosphere because it comes out of the nozzle so fast and uncontrolled.” Standardizing on one brand of consumables has also improved OEM’s inventory management system, which in turn reduces downtime and keeps their welders more productive. “Labor is one of a company’s biggest costs, so we try to eliminate non-value-added time as much as possible,” Exner explained. “Standardizing on one brand of consumables means that if one operator runs out of tips, he can borrow one from his neighbor, rather than spending time going to the crib trying to track down a tip of the same make and model as the one he is using.” Although OEM still has a few customers who require a departure from the one process, one gas, one wire, one gun practice, the vast majority of their customers have been thrilled with the results of their “rule of ones” philosophy – both in terms of the cost and quality of OEM’s product. “At a time when most of our suppliers are increasing their prices, our customers are asking for price breaks,” Exner explained. “Our investment in implementing lean manufacturing principles into our welding operations has allowed us to provide our customers with not only better prices, but also a better product.” Best of all, it has positioned OEM to continue their tremendous growth without worrying about incorporating new product runs into their existing operations.

The liner is both one of the simplest and most important components of a MIG gun. Its sole purpose is to guide the welding wire from the wire feeder, through the gun cable and up to the contact tip. If it is not performing this task properly, the gun is virtually worthless. A number of problems can interfere with the liner’s ability to properly guide the wire through the welding cable. When the wire does not feed correctly, weld quality problems may arise that lead to increased operator downtime and costly rework. The following is a discussion to help you get the best performance from your MIG gun liner and troubleshoot problems when they occur. There’s an old saying that prevention is the best medicine, and this holds true with MIG gun liners as well. Proactive maintenance can eliminate problems before they arise and reduce operator downtime, more serious equipment failures and costly rework. Buy quality: The quality of a liner can also impact your welding performance, productivity and operator downtime. A premium quality liner maintains a consistent inside diameter throughout its length. This is critical because variances as small as a few thousandths of an inch can result in wire feeding problems requiring time-consuming liner replacement. Choose the right size: To maximize the performance of your MIG equipment, choose the correct liner size for the wire being used. Small diameter welding wires, .023-in. through .045-in., have relatively low columnar strength, which, when paired with an oversized liner, can cause the wire to wander or drift within the liner. This in turn leads to poor wire feeding and premature liner failure due to excessive wear. By contrast, larger diameter welding wires, 1/16-in. through 1/8-in., have much higher columnar strength. Just make sure the liner you choose is large enough to feed the welding wire you are using. Don’t overdo it: Most MIG gun liners are made from coiled steel wire, known as music or piano wire, which gives the liner a good balance of rigidity and flexibility and allows it to guide the welding wire through a tightly bent cable without kinking. Nevertheless, bending the cable too much can cause poor wire feeding, premature liner wear and birdnesting (explained below). Proper replacement: Improperly installing the liner can lead to wire feeding problems such as birdnesting, which results in downtime and reduced productivity. Avoid twisting the cable when trimming the liner, as this can cause it to be too short, resulting in gaps that can lead to erratic wire feeding. There are also consumables — contact tip, nozzle, gas diffuser and liner — available in the marketplace that allow for error-proof liner installation. The diffuser locks the liner in place and concentrically aligns it with both the power pin and contact tip with no gaps or misalignments (and without the use of fasteners). There is no liner measuring required during installation or replacement. The welding operator or maintenance personnel simply feeds the liner through the neck of the gun, locks it in place and cuts the liner flush with the back of the power pin. Regular maintenance: Tight bends in the cable increase friction between the liner and the welding wire. This friction makes it more difficult to push the wire through the liner, causing wear and metal fragments to accumulate inside the liner. Eventually these tiny particles can build up and cause serious wire feed blockages. This occurs to a lesser degree even with cables that are not bent tightly, so it’s a good idea to periodically clear out the liner with compressed air. Poor or erratic wire feeding, a loss of amperage or frequent contact tip burnback are all signs of liner problems. Unfortunately, because of the time it takes to replace the liner, this is often one of the last components checked during a troubleshooting effort. Poor wire feeding: Erratic or poor wire feeding can result when the liner becomes worn out in certain spots, is trimmed incorrectly during replacement or has excessive debris buildup in the liner. Excessive debris can usually be cleared out by removing the wire and forcing compressed air through the liner (without removing it from the cable). In most cases, a worn out liner will need to be replaced. With a conventional liner, trimming the liner accurately during replacement is critical. Liners trimmed too long or too short can cause wire feeding issues, wire chatter, an erratic arc and/or burnbacks. Using a liner gauge is recommended when trimming a conventional liner. Another option is to use a consumables system that locks the liner in place at the front and back of the gun while concentrically aligning it to the contact tip and power pin. With this type of system, the liner is simply trimmed flush with the power pin at the back of the gun — no measuring required. The result is a flawless, gap-free wire-feeding path. Birdnesting: If the welding wire’s path of travel through a MIG gun is blocked while the wire feeder is pushing it, a tangled mess of wire called a birdnest could be the result. A birdnest can be caused by a liner that is trimmed too short, clogged, or the wrong size (too small or large for the wire diameter). The above section on proper liner replacement describes how birdnesting can result from trimming a liner too short. Electrical short: The liner is not designed to carry welding current, so a dramatic loss of current at the arc will result if loose cable connections or a degraded cable make it the path of least electrical resistance. One common sign that this has occurred is a discolored liner and excessive heat build up along the power cable. The discoloration is caused by heat and indicates weld current is being carried through the liner instead of the gun’s power cable. A degraded cable will require repair or replacement. The liner is not visible during normal welding operations, but that doesn’t mean it can be overlooked as a significant factor in weld quality and productivity. Thankfully, performing some very basic maintenance and being able to troubleshoot a malfunctioning liner will help you maintain consistent weld quality and optimum productivity.

Even though many consider MIG gun consumables to be a commodity—a simple ‘throw-away’ item—these components play a critical role in achieving good welding performance and quality. They can also impact the overall productivity and cost of your welding operation, often in some rather subtle ways. For both reasons, it is crucial to find the best possible, longest lasting consumables for your application and maintain them with as much care as you would any other welding equipment. MIG gun consumables, which comprise the front-end part of the gun—the nozzle, retaining head and contact tip—plus the liner, are at the heart of the welding process. These components are responsible for properly feeding the welding wire and for establishing the electrical conductivity necessary to create the arc. And while the welding power source you use undoubtedly influences your operation’s performance, so too can your consumables. In fact, MIG gun consumables are one of the most overlooked portions of the welding operation. Without proper installation, storage and maintenance, these components can cause significant downtime for changeover and added cost for inventory, waste and rework. Fortunately, through a few simple measures, you can easily extend the life of these components and positively affect the efficiency and profit of your welding operation. Here’s how. To prevent such issues, first consider the nozzle itself. Look for a smooth, non-porous surface that is free of sharp edges or flat surfaces, as it better resists spatter accumulation and therefore, lasts longer. Also, choose nozzles that have some ‘mass’ to them—they should look and feel sturdy. These heavier nozzles may cost more up front, but their longevity can help prevent downtime that will likely cost you more money over time. Proper nozzle storage and handling is critical to extending the life of this component. First, keep the nozzle in the plastic packaging in which it shipped until you are ready to use it. Unwrapping the nozzle and storing it in a bin, while a common practice, causes dents and scratches on the surface of the nozzle, making it more prone to spatter accumulation. Nozzles that are unprotected from the environment can also accumulate air-borne contaminants or debris, which if introduced into the weld puddle may cause defects that need to be reworked. Generally, semi-automatic MIG gun applications use slip-on nozzles. When installing one, make certain to securely connect the nozzle to the retaining head to prevent shielding gas leaks that can lead to weld quality issues. Also, be mindful whether you have any debris, grease or oil on your hands or gloves. Keep the nozzle as clean as possible to prevent such contaminants from entering the weld puddle later on or causing premature failure of the component. Consider using an anti-spatter compound (gels are commonly used in semi-automatic applications) to reduce the amount of spatter that adheres to the nozzle. Apply the compound by dipping only the front inch and a half of the nozzle into the compound. Do not submerge the nozzle in the compound, as this can saturate the porous insulator inside the nozzle, causing it to fail prematurely, accumulate spatter more readily and/or create an erratic arc—all factors that lead to downtime, extra costs and waste associated with changing over to a new nozzle. Next, visually inspect the inside and outside of the nozzle periodically for spatter, ideally several times throughout the welding shift. If it appears clogged, clean the nozzle using a tool specifically for the job or replace it if necessary. Finally, never use the nozzle to chip away at spatter or for any other hammering purpose. Doing so damages not only the MIG gun, but it also can dent or misshape the nozzle, rendering it unusable. Good welding performance depends on good electrical conductivity. Look for consumables with a tapered design that locks conductive parts — like the contact tip, gas diffuser and MIG gun neck — together. This is particularly important since the gas diffuser is the component that forms the connection between the nozzle and the MIG gun neck, and holds the contact tip in place. It also provides the surface area necessary to carry the electrical current to the contact tip to create an arc. If the connection between the gas diffuser and contact tip is not secure, it can cause electrical resistance that leads to overheating, causing the components to fail. To ensure your arc remains stable and that the contact tip does not become too hot, use the correct diameter contact tip for your welding wire. Also, look for a contact tip design that buries the tip further into the gas diffuser, as this keeps the tip away from the heat and allows the shielding gas to cool the contact tip tail — keeping the contact tip running cooler for a longer life. Similar to nozzles, store and handle the contact tip and retaining head properly. Keep them in their packages until you are ready to use them and take care that they are free of contaminants. For instance, any oil or debris present on a contact tip can become trapped when you thread the tip into the retaining head, which in turn can cause the components to overheat and fail during the welding process. When installing a retaining head, tighten the component to the manufacturer’s specifications by hand or by using a recommended tool. This step ensures a secure connection between the retaining head and the MIG gun neck and prevents shielding gas leaks and/or electrical resistance. Similarly, when installing the contact tip tighten the components securely using a pair of welding pliers (sometimes called welpers). Do not use wire cutters, as these can cause scratches in the contact tip or misshape it entirely—any such damage shortens the tip’s life and may lead to costly downtime and rework. Contact tips with coarse threads are a good option to speed replacement since they require fewer turns, and this design helps minimize the opportunity for cross-threading. One full turn disengages the contact tip from the diffuser. A MIG gun liner spans the length from the front of the MIG gun through to the power pin and is the conduit through which the welding wire feeds. It is generally composed of a steel coil, but if you are welding with aluminum wire you’ll need to choose a nylon liner or one of similar material. As when choosing your contact tip, select the correct diameter liner for your welding wire to prevent wire-feeding, arc wandering or other problems like bird nesting. Bird nesting occurs when the welding wire becomes tangled in the drive rolls; it is also caused by an improperly installed liner and/or by using the wrong drive roll tension. Properly trimming your MIG gun liner significantly increases the longevity of this component. Always follow the manufacturer’s recommendations, using the proper cutting tools and trimming the liner to the correct length. A good way to achieve error-proof liner installation is to use a consumable system that eliminates the need to measure the liner and with it the potential to trim it incorrectly. These liners load through the neck at the front of the gun, are locked in place and trimmed flush with the power pin at the back of the gun. Liners like these are very helpful, as cutting the liner too short causes the welding wire to feed improperly through the contact tip, resulting in wire chatter, an erratic arc and the potential for burnbacks. Conversely, a liner that is trimmed too long can kink, which leads to feeding issues and, again, shortens the life of the contact tip. When installing your MIG gun liner, keep it (as much as possible) away from contaminants, as debris causes blockages that lead to feeding problems and welding wire damage. Do not let the liner drag on the floor, but instead wrap it in a coil in one hand as you install it, and make certain that your hands or gloves are clean. The frequency with which you need to change your MIG gun liner depends largely on the welding application, the type of welding wire used, the duration of welding and the amperage. Consider tracking the length of time from one installation to another, using that timeframe as a guideline for how long your liner will likely last. Some welding operators also blow compressed air through the liner periodically to extend the component’s life. Other means to increase the life of your MIG gun liner include using the shortest MIG gun cable length possible for your particular welding application and keeping the cable clear of any equipment, such as a forklift, that could damage it. Both measures help prevent kinking and again minimize the chance of poor wire feeding that could lead to costly downtime. While MIG gun components comprise just one portion of your welding operation, being mindful of the impact they have on quality and cost is important. Nozzles, contact tips, retaining heads and liners each perform a function vital to the whole of the welding process and should be purchased, installed and maintained with care. Doing so not only prevents the cost of downtime for changeover, maintaining excessive inventory and rework, but it can affect your bottom line—positively—through better weld quality and greater productivity.