The Road to Welding Automation

Why and When to Take the Journey

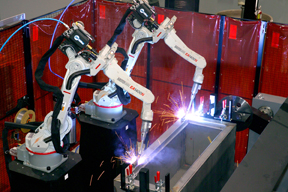

Today, more companies than ever are automating portions, if not the entirety of their welding operations. The reasons are many: to address the welder shortage, improve quality, decrease waste and rework, and/or to increase productivity. Not all companies that attempt the automation journey, however, are successful. In fact, those that begin without a well-thought-out roadmap are risking valuable time and investments and are likely to miss the full benefits of welding automation.

On the other hand, companies that begin with a careful examination of their welding needs and current processes—including an accurate assessment of workflow and an evaluation of the potential return on investment (ROI) and develop a detailed plan with clearly established goals are likely to achieve welding automation success.

What’s the Benefit?

quality, increase productivity and help address the shortage of

skilled welders.

On average, labor accounts for approximately 70 percent of any welded part’s cost. An automated system has the potential for reducing that cost, as a robot can typically do the work of two to four people, operating without attention deficits or bad days. Companies cannot, however, simply purchase an automated system and let it go. A skilled welding operator is needed to program the equipment, which may involve additional training to upgrade his or her skill sets, and may also require alleviating this welding operator of some existing tasks.

With the right automated system, a company can significantly improve first-pass weld quality and reduce the need for scrapping or reworking parts. It can also minimize or eliminate spatter, which in turn reduces the need to apply anti-spatter or perform post-weld clean up—both labor-intensive processes. Plus, if a company currently has personnel applying anti-spatter, it may be able to free up that manpower for other, more productive uses elsewhere.

An automated system can reduce overwelding, a common and costly occurrence associated with the semi-automatic process. For example, if a company has welding operators who weld a bead that is 1/8-inch too large on every pass, it can potentially double the cost of welding (both for labor and for filler metals), and over-welding may adversely affect the integrity of the part. Automation can prevent this problem.

Finally, robots are fast. They don’t have to weld all day to be profitable; they only have to weld more quickly than a manual welding operator—and they do. That fact increases productivity, and creating the same number of parts in a shorter time also decreases labor costs and raises profitability.

While these benefits may immediately beg the question, “How can our company automate?” there are a few questions that need to be answered first.

Repeat That?

One of the first things to ask when considering welding automation is this: “Does the company have a blueprint, preferably an electronic blueprint, of its parts?” If it doesn’t, it probably won’t meet the basic criterion necessary to ensure the part is repeatable, and repeatability is the key to automation.

An automated system, whether robotic or fixed, needs to weld in the same place every time. If a part’s design is unable to hold its tolerancesif there are gap and/or fit-up issuesthe company will simply be automating a broken process, which in turn, can lead to increased rework and scrap.

If a company currently relies on its welding operators to compensate for fit-up issues, it will need to look upstream in the manufacturing process to ensure consistency. What processes will need to change to make sure uniform parts are sent downstream by these welding operators? Or, if vendors supply the components, can they guarantee that consistency?

Robotics or Fixed Automation?

There is no single automation solution that is best for every company. The best solution will depend on many factors, including the expected lifetime of the job, the cost of tooling involved and the flexibility offered.

Fixed automation is the most efficient and cost-effective way to weld certain components, such as those requiring simple repetitive straight welds or round welds, where the part is rotated on a lathe. For a company that wants to redeploy the asset when the current job ends, however, a robotic welding system offers more flexibility. A robot can also hold programs for multiple jobs, so, depending on volume, it may be able to handle the tasks of several fixed-automation systems.

There is a certain volume of parts that will justify the investment of automation for each company, and an accurate assessment of goals and workflow can help determine what that volume is. If a company makes only small runs of parts, automation becomes more challenging. If, however, a company can identify two or three components that can be automated, a robot that can be programmed to recognize those parts can offer greater flexibility and may benefit even small fabricators who may not have significant volume of a single part.

Although a robot is more expensive than a fixed-automation system, companies should be sure to consider the cost of the necessary tooling before deciding between the two. Fixed automation systems can become quite expensive if extensive changes are required to retool a part to ensure it can be welded consistently.

Ready to Automate?

A streamlined workflow is one of automation’s benefits. To achieve it, however, it is necessary to look beyond the weld cell to ensure your facility can accommodate a smooth flow of materials. It would make little sense, for instance, to invest in an automated system to increase your productivity and then place it in a corner where each part has to be handled twice.

Companies should have a dependable supply of parts in order to avoid moving a bottleneck from one area to another and should also look at the expected cycle time of the robot. Can personnel supply parts to keep up with the demand of the automated system’s cycle time? If not, the supply of parts, including where they are stored and how they are moved, will need to be adjusted if automation is to be successful. Otherwise, a robot will sit idle waiting for components to come down the line—a costly and counterproductive state for a company to find its automated welding system.

Companies will need to have the right power and gas systems in place or factor in the cost of implementing these systems. To move to an automated system, a facility needs a 480-volt, three-phase power supply, as well as bulk delivery of gas and wire. A gas manifold system may add to the initial cost of automation, but will minimize downtime for changing gas cylinders in the long run.

Determining who will oversee the automated system and providing training is also essential. Most robot OEMs offer a weeklong training course explaining how to operate the equipment. This course, followed by a week of advanced programming, is recommended.

Because there is more to welding automation than simply purchasing a robot, partnering with a competent integrator or automation specialist can help ensure success. The automation specialist will…

- Help determine if parts are suitable for automation, and, if not, what is required to make them suitable.

- Analyze the workflow and facility to identify potential roadblocks.

- Analyze the true costs involved, including facility updates and tooling.

- Determine the potential payback of the automation investment.

- Help identify goals and develop a precise plan and timetable to achieve those goals.

- Explain automation options and help select those that best fit the company’s needs.

- Help select a welding power source that has the flexibility to maximize travel speed, minimize spatter, eliminate over-welding, provide great arc starting characteristics and increase first-pass weld quality.

Remember, there is no single path to successful welding automation. Still, a well-thought-out plan that includes accurate evaluations is a good start to the journey.