Air-Cooled vs. Water-Cooled MIG Gun: Which is Right for You?

For some companies, choosing between an air-cooled or a water-cooled MIG welding system is pretty cut and dry. Mobile fabrication and repair companies that weld sheet metal for only a few minutes every hour will have little need for the benefits provided by a water-cooled system. Likewise, shops with stationary equipment that repeatedly weld at 800 amps probably won’t be able to find an air-cooled system that can handle the heat of the application.

But for many companies, however, it’s not such an easy decision. Each type of cooling system has advantages and disadvantages, and deciding which is right for your company requires a careful analysis of the following factors:

- Amperage requirements

- Duty cycle

- Torch weight and operator comfort

- Work site location

- Cost

First Things First

Keeping MIG welding equipment cool is necessary to protect the power cable, gun and consumables from damage due to the radiant heat from the arc and the resistive heat from the electrical components in the welding circuit. It also protects the operator from heat-related injuries and provides more comfortable working conditions.

A water-cooled MIG welding system pumps a cooling solution from a radiator unit, usually integrated inside or near the power source, through cooling hoses inside the power cable and into the gun handle, neck and consumables. The coolant returns to the radiator where the radiator’s baffling system releases the heat absorbed by the coolant. The ambient air and shielding gas further disperses the heat from the welding arc.

An air-cooled MIG welding system relies solely on the ambient air and shielding gas to dissipate heat that builds up along the length of the welding circuit. Air-cooled systems use much thicker copper cabling than water-cooled systems, which allows the cable to transfer the electricity to the gun without building up excessive heat from electrical resistance. By contrast, water-cooled systems use relatively little copper in their power cables because the cooling solution carries away the resistive heat before it builds up and damages the equipment.

Amperage Requirements

The welding amperage will be an important factor to weigh when deciding between an air- or water-cooled system. In general, air-cooled systems are better for low amperages and water-cooled systems are better for high-amperage applications.

Air-cooled guns are available with ratings from 150 – 600 amps, and water-cooled guns range from 300 – 600 amps. These ratings represent the current loads under which the guns become so warm that they are uncomfortable for the average operator to hold. Because guns are rarely used to the limits of their duty cycle, it’s often a good idea to purchase a gun that’s rated to a lower amperage than the maximum to which it will be exposed. For example, a 300-amp gun can handle more than 400 amps and it is substantially lighter and more maneuverable than a 400-amp gun.

Duty Cycle

Closely related to a gun’s amperage capacity is its duty cycle — the amount of time during a 10-minute cycle that the gun can operate at its rated capacity without becoming uncomfortably hot. Exceeding a gun’s duty cycle can lead to operator pain and will also reduce weld quality and decrease the service life of the gun and consumables.

There is no industry standard for establishing amperage ratings based on duty cycle, so two guns both rated to 400 amps could have significantly different duty cycles. This makes it important for the customer to consider a gun’s amperage rating and duty cycle together in order to form an accurate assessment of the MIG gun’s capabilities.

Gun Weight and Operator Comfort

Welding all day long in an industrial or construction environment can take a significant toll on the hands, arms, shoulders and back (not to mention most other body parts) of a welding operator. A heavy, bulky and difficult-to-maneuver gun only exacerbates these aches and pains, and it accelerates the time they take to set in.

One of the benefits of water-cooled guns is their size and weight. Because water is more efficient than air at carrying away heat that builds up from the heat of the arc and electrical resistance, water-cooled guns use less wire for their cables and smaller gun components, resulting in reduced operator fatigue.

Although air-cooled guns are generally heavier and more difficult to maneuver than water-cooled guns, significant differences in gun design between manufacturers can also have a big impact on how quickly the gun contributes to fatigue. It’s a good idea to physically hold a gun to determine its comfort level prior to making a purchase.

Worksite Location

Because water-cooled guns require more equipment than air-cooled systems, they can be impractical for applications that require portability. Transporting the cooling system and coolant hoses of a water-cooled MIG gun can reduce productivity and cause unnecessary downtime. Water-cooled systems are most practical in applications where they will be stationary or moved very little. By contrast, air-cooled MIG guns are easily carried and moved from site to site within a shop or out in the field.

Cost

Finally, companies must evaluate the cost of the two systems before making a purchasing decision. Doing so, however, is not as simple as looking at their respective price tags. In addition to the sticker price of the systems, companies need to consider maintenance costs as well as productivity and downtime costs associated with operator fatigue and equipment longevity.

A water-cooled system requires the purchase of a coolant flow system (including radiator, pump, hose lines, etc.), which leads to a higher up-front cost than an air-cooled system. Because water-cooled systems require a special coolant solution in order to avoid mineral or algae build-up in the coolant lines and radiator, they involve more extensive maintenance and higher operational costs than an air-cooled system. Furthermore, coolant leaks can lead to equipment damage and weld discontinuities that add to the cost of owning a water-cooled system.

In addition to being less expensive up-front, an air-cooled system also offers the advantage of being better suited to low amperage applications. Thus, for example, a company that needs to weld at 150 amps and 600 amps in the same weld cell can keep its costs down by purchasing a single air-cooled system rather than a water-cooled system for the high-amperage applications and an air-cooled system for the low-amperage applications.

That doesn’t mean, however, that a water-cooled system is more expensive than an air-cooled system. As mentioned earlier, a water-cooled MIG gun is much smaller and more lightweight than an air-cooled MIG gun, which can help decrease operator fatigue and increase productivity over the course of a day.

When set up properly, a water-cooled MIG gun can provide significant long-term cost savings compared to an air-cooled gun. The coolant in a water-cooled system also extends the service life of the consumables by drawing away the heat absorbed from the arc. Longer consumable life means less downtime for changeovers and lower consumables inventory.

Conclusion

Unfortunately, there is no one-size-fits-all formula for choosing between an air-cooled and a water-cooled MIG welding system. Each company must analyze their welding operations and determine which type of system offers the benefits most important to them. Considering these factors — cost, worksite location, gun weight and operator comfort, duty cycle and amperage requirements — will provide a good start toward making a wise decision.

Find an air– or water-cooled MIG Gun for Your Application

MIG guns and consumables are sometimes an afterthought when purchasing a welding system, but considering that they are the most handled piece of welding equipment and are exposed to the most environmental and operator abuse, they can have a significant impact on weld quality, productivity and operator downtime. Much of the reason MIG guns and consumables do not receive their fair share of attention within the equipment selection process arises from common misconceptions about their importance in the welding operation. The following are five of the most common myths surrounding MIG guns and consumables and the corresponding truths that can help you improve productivity, reduce costs and increase operator efficiency. Truth — MIG guns vary substantially in quality, performance and value. Purchasing a quality gun designed with features that minimize downtime, weld quality problems and premature equipment failures can result in significant long-term savings. These efficiencies can save you far more than the price difference between a high performance and inferior quality gun. Conversely, a high quality MIG gun will offer features, design elements and construction that allow them to provide reduced operator fatigue and fewer burnbacks, birdnests and other problems. When evaluating the long term value of a MIG gun and consumables system, you need to consider the service life of the gun, replacement parts costs, the cost of downtime when the gun needs servicing, and the ease with which components can be changed. First, consider the downtime that can result from choosing MIG guns and consumables without looking into their full long-term cost. If a gun’s only selling point is its price, it could be manufactured with inferior components that don’t last as long as high quality components, are more difficult to replace when they do need replacing and cause the premature failure of other components. An example of the difference between high and low-quality components can be found in the power cable fittings. Set-screw fittings can loosen over time and result in poor electrical conductivity and increased resistance. On their own, these problems can reduce weld quality and require reworking or scraping parts. Uncorrected, these problems can also lead to increased resistive heat at the point of the fitting. This heat causes additional stress and shortens the service life of the gun and cable. By contrast, a high performance gun often uses compression fittings, which produce a more secure connection between the cable and gun and will be less likely to result in weld defects or cause the deterioration of other components. Consumables are another component in which trying to save a couple bucks on the purchase price could become very costly in the long run. A high quality consumables system requires fewer tip changeovers and those changeovers are often faster, reducing both equipment costs and operator downtime. Overall, the cost of operator downtime should be your company’s primary reason to avoid choosing guns and consumables based solely on price. If each of your welders averages three hours a week adjusting and replacing MIG gun components, at an average employee cost of $30/hour, that downtime adds up to $4,680 per year in unnecessary costs (and that’s not even counting the material cost resulting from scrapped work). Truth — The MIG gun’s consumables — the nozzle, diffuser and contact tip — provide shielding gas and are the last component of the welding system to come into contact with the welding wire before it enters the weld pool. As such, consumables can have a big impact on weld quality and productivity, and selecting high quality ones and properly maintaining them is essential. Consumables differ considerably by brand in terms of both design and material quality. Good quality consumables provide a large contact area between the diffuser and the contact tip and feature a secure locking mechanism to keep the contact tip and diffuser fitting tightly together. These features mitigate weld quality problems related to inconsistent electrical transfer, and also the frequency of contact tip burnbacks — a noteworthy source of downtime. Equally important to selecting the right consumables is maintaining them properly. Good quality consumables resist built-up better than low quality ones, however, no consumables can completely avoid spatter build up. Use a needle nose pliers, nozzle reamer or other device to dislodge built up spatter to prevent interruptions in shielding gas flow and corresponding weld defects. You should inspect the nozzle for spatter build up several times a day and clean it out as needed. In addition to checking and cleaning out spatter, you should check to ensure the contact tip sits tightly in the diffuser and that the inside bore has not become excessively worn. Non-threaded contact tips can be rotated in place to provide a new contact surface with the welding wire when it becomes worn on one side. Some threaded contact tips allow you to rotate them 180-degrees to also provide extended tip life. Truth — Compared to the time spent reworking bad welds and replacing severely damaged components, spending a few minutes each day inspecting and maintaining the MIG gun and consumables is a bargain. Identifying potential problems early is essential to avoiding the much higher costs that can result from allowing a minor problem to grow into a major headache. For example, a damaged O-ring on the feeder connection is very easy and inexpensive to repair, but left unchecked, it can create very costly weld porosity. Because MIG guns have few moving parts and are relatively simple to inspect, you should check the connections between the wire feeder, the cable, the gun, the neck and the consumables on a daily basis to ensure they are tight and undamaged. A loose or damaged fitting can create resistive heat build-up, poor weld quality and shortened component life. Consumables should be checked several times throughout the day to ensure the inside bore of the contact tip is not excessively worn down and that the shielding gas flow is not obstructed by spatter in the nozzle. The liner is one of the most difficult MIG gun components to inspect, so it’s often best to use compressed air to clean out any metal shavings and debris during each wire changeover. Routine inspection and maintenance should take up no more than 10 to 15 minutes per day, which averages out to about $1,300 per year in downtime. By contrast, reworking or scrapping bad welds can take up several hours each time it happens. If an operator spends four hours per week fixing weld defects caused by improperly maintained equipment, that non-production time costs his employer roughly $6,240 per year. Even more importantly, it can cause the company to fall behind on product deadlines and threaten their client relationships. Truth — It almost seems contradictory that most companies are making a mistake by purchasing a 400-amp MIG gun when their applications require 375 amps. In truth, the problem with overmatching the gun to the application is that most operators only weld for 30 to 50 percent of the time, which means that they can easily get by with a 300-amp gun and rarely, if ever, exceed its duty cycle in an application requiring 375 amps. A 400-amp gun could certainly handle the demands of the application, but it is also heavier and bulkier, leading to earlier operator fatigue and reducing productivity. In order to achieve maximum operator efficiency, companies need to analyze their specific welding demands and purchase a gun that is as small and light as possible while still meeting the amperage requirements of the application. Another factor you should consider when purchasing a MIG gun is the weight and size differences between brands. In many cases, a gun from one company rated to 400 amps will be considerably heavier and bulkier than a similarly rated gun from another company. Not all gun manufacturers label and market their guns to a 100 percent duty cycle rating, however, so be sure to verify that you are making an apples-to-apples comparison when evaluating MIG guns from different manufacturers. For example, company A’s 300-amp MIG gun might be able to weld at 300 amps at 100 percent duty cycle, but company B might also make a gun that they call a 300-amp MIG gun that is only rated to 300 amps at 40 percent duty cycle. The amperage to duty-cycle ratings are usually available in the spec sheets from most major MIG gun manufacturers, so check there to make sure the gun is able to handle your applications. Truth — It’s true, properly functioning MIG gun liners, regardless of brand, do not have a significant impact on welding performance. It’s when the liner is not functioning properly that its importance in the welding operation — and the difference between a high and a low quality liner—becomes clear. The liner’s main function is to provide unobstructed passage for the welding wire to travel from the feeder, though the cable and gun into the consumables. It’s a very simple role within the welding operation, yet a number of problems can arise in the liner that can lead to weld defects and lost productivity. A high quality liner can provide a more consistent inside diameter through which the welding wire travels, thereby reducing friction and extending the service life of the liner as well as the time that it takes for wire filings to clog the liner—one of the most frequent sources of liner-related downtime. The liner is most susceptible to this problem when the cable is bent too far and increases the friction between the wire and liner. Other causes of clogged liners include using an incorrect liner size and trimming it improperly. In both cases, the liner can shave metal filings from the welding wire and become clogged, leading to erratic wire feeding, poor weld quality and birdnests. Because the copper stranding in MIG gun cables is wound in a helix pattern, the cable shrinks when it is twisted. Trimming a new liner to the length of a twisted cable can cause the liner to be too short when the cable is straightened out, leaving an empty space in which the welding wire can become lodged and birdnest. Additional downtime can be saved by using an easily-replaced partial liner that installs from the front of the gun and only goes through the gun’s neck. The most wire-to-liner friction occurs in the neck, so that part of the liner is usually the first to wear out. Rather than spending 20 minutes replacing the entire liner when only that portion becomes worn, some companies offer partial liners that can be changed in as little as two minutes. In times of economic uncertainty, it’s understandable that companies would seek to reduce their production costs by purchasing less expensive equipment. However, the true cost of purchasing lower quality equipment — lost productivity, reduced weld quality, increased scrap and excessive downtime — can far outpace the cost of selecting higher quality MIG guns and consumables.

A welding operator typically spends much less than 50 percent of an eight-hour day engaged specifically in the act of welding, with the remaining portion allocated to joint preparation, part fit-up and movement, and other activities that contribute to the throughput of the welding operation. Still, during that arc-on time, the importance of helping the welding operator remain comfortable and cool can’t be stressed enough. Simply stated, by ensuring good operator comfort companies can lessen the chances of injuries associated with repetitive movement, reduce overall operator fatigue and lessen insurance rates or worker compensation claims. The result? A more content employee and the potential for greater productivity and profitability. Not surprisingly, the MIG gun that a welding operator uses can have a direct impact on comfort. Factors including the MIG gun’s amperage, along with its handle and cable styles all contribute to the equipment’s weight and maneuverability, and should be considered when selecting a MIG gun for the welding operation. Other factors, such as protecting against the MIG gun’s heat output is also critical, both to the welding operator’s comfort and safety, too. It is not uncommon in a welding operation to find MIG guns that are rated at a higher amperage than necessary for the given application. One of the reasons for this occurrence is the common misconception that the MIG gun used should be rated to the highest amperage at which the welding operator will be welding. For example, if an application requires 400 amps, it’s very common to find a welding operator using a 400-amp gun. While the gun in this example will undoubtedly do the job, the higher amperage gun also weighs more than a lighter amperage one and tends to be less flexible—both factors that impact the welding operator’s comfort and his or her ability to maneuver the MIG gun easily. As a general rule, selecting the lightest, most flexible MIG gun for the application is the best choice. In the case of a 400-amp application, a MIG gun rated at 300 amps may suffice. There are two reasons for this assertion. First, MIG gun amperages, which are established by CE (Conformité Européenne or European Conformity) in Canada and NEMA (National Electrical Manufacturer’s Association) in the United States, reflect the temperatures above which the handle or the cable on a MIG gun become uncomfortable. They do not indicate the point at which the MIG gun risks damage or failure. Secondly, given that a typical welding operator (as mentioned previously) typically welds only a small portion of the workday, it is highly unlikely that he or she would be operating the gun at full amperage and full duty cycle at all times. Duty cycle is defined by the amount of arc-on time in a 10-minute period that the equipment can be operated at maximum capacity. Some MIG guns will offer 100 percent duty cycle, while others are rated 60 percent or below. As a result of these two factors, a lower amperage model can often be used for a slightly higher amperage application without damaging the gun or heating up to the point of making the welding operator uncomfortable. The lower amperage MIG gun also offers the added benefit of being lighter and more flexible for the welding operator. In many cases, these models will also be more cost effective. It is important, however, to research the MIG gun’s duty cycle prior to purchasing it in order to ensure it offers the necessary capacity for the application. Another important factor in maintaining a good comfort level for the welding operator is selecting a MIG gun with the appropriate handle, neck and cables for the application. Typically, as a MIG gun’s amperage decreases so too does the size of the gun handle and the cable, which makes the equipment that much more comfortable for the welding operator. Because every application is different, however, it is not always possible to use a lower amperage MIG gun. For that reason, it is important to implement other safeguards to keep the welding operator comfortable. First, it is important to match the handle style to the welding operator’s preference. MIG gun manufacturers often offer handles in curved and straight models, either of which may be more comfortable for one welding operator compared to another. The goal for both types of handles, however, is the same: to choose a light-weight, comfortable style that also meets the MIG gun and application’s amperage and duty cycle requirements. As a rule, a smaller handle will be easier for the welding operator to maneuver. Additionally, some MIG gun manufacturers offer ventilated handles, which help reduce heat and are more comfortable to hold when welding for longer periods of time. In some instances, a water-cooled MIG gun may provide the smaller size desired for an application and would be a good choice to reduce operator fatigue on higher amperage applications, especially in a shop setting. As when selecting MIG gun or a handle, a good rule of thumb is also to select the smallest and shortest power cable possible that can still meet the needs of the application. Smaller and shorter power cables are lighter and more flexible and can, therefore, reduce operator fatigue. They can also minimize clutter in the work space and prevent excessive coiling that may be cumbersome for the welding operator to rectify and that could also lead to poor wire feeding. An added advantage is that smaller and shorter cables tend to be less expensive, as well. In addition to fixed necks, many MIG guns are available with rotatable and flexible necks in various lengths and angles that can increase the welding operator’s comfort. The advantage of these styles is that they provide the welding operator with the option to select one that will best suit the joint access required for an application. For example, flexible necks can be easily adjusted to fit different welding angles and reach difficult joints that may be restricted or otherwise awkward to reach. This features helps keep the welding operator from straining to reach a particular weld joint and risking fatigue or injury. Similarly, rotatable necks are a good option for welding out-of-position (including overhead), as they can be adjusted to reach the weld joint without changing the gun handle or its position. Both of these type of MIG gun necks can also simplify inventory and reduce downtime for neck changeover, as they can be used on multiple applications. Some MIG gun manufacturers also offer neck couplers, which allow the welding operator to connect multiple necks together to reach especially difficult joints comfortably. There are two main types of heat in a welding operation: radiant heat from the arc and resistive heat from the cable. To protect against both types of heat, it is important that the welding operator always wear the proper protective apparel, including a helmet, welding gloves and a welding jacket or sleeves. Radiant heat is heat that reflects from the welding arc and base metal back to the handle. If the welding operator welds on shiny materials, such as aluminum or stainless steel, it will likely reflect more heat that a duller mild steel, for example. Using a longer neck to the MIG gun can help protect the welding operator from radiant heat by placing the handle further back from the arc. Adding a neck grip can further increase comfort. Neck grips are available through select MIG gun manufacturers and are usually composed of high-temperature silicon rubber. They slide over the neck to protect the welding operator from heat exposure and related fatigue. These accessories offer the added benefit of increasing control for welding operators who like to rest the neck on their hand or forearm, using it as a pivot point to maneuver the MIG gun. Because the neck can also carry heat to the handle, it is important to use front-end consumables—nozzles, contact tips and diffusers—that remain cool. Be certain to look for consumables that fit snugly together, as this feature will minimize electrical resistance and reduce heat output. Also, consider the shielding gas being used for the applications as a means to minimize heat in the welding operation and help the welding operator remain cooler. Argon, for example tends to create a hotter arc than does pure CO2 shielding gas. In fact, MIG guns operating with Argon in the mix often reach the MIG gun’s rated temperature at a lower amperage than when using pure CO2. While it may not be possible to choose which shielding gas to use (a particular application often specifies gas usage), if operating an Argon applications, a welding operator could take other precautions (as mentioned above) to help stay cool. To protect against resistive heat, it is important to have a large enough power cable for the job—but not too large as to make it difficult to maneuver—and also to prevent kinking of the power cable whenever possible. When selecting a MIG gun for any application, the goal is two-fold: to have the right equipment for the application and to keep the welding operator as comfortable as possible. Through careful selection of the proper amperage MIG gun, along with choosing an appropriate handle, cable and neck that goal is reasonable to achieve. Also, by taking precautions against heat exposure, a welding operator can ensure that he or she will be able complete the required welds with minimal discomfort. Remember to research the MIG guns available in the market place, in addition to the application at hand. Consider the actual amount of time the welding operator will be welding and on what type of material, too. Doing so can help ensure that the selected MIG gun strikes a good balance between size and capacity.

Selecting the right MIG gun for your welding application, and maintaining it properly, is just as important to your overall productivity as any other part of the welding operation. Unfortunately, MIG guns are very often an overlooked part of the welding system. The reality is, however, that in addition to being responsible for delivering the current, wire and shielding gas to the weld puddle, your MIG gun can also have a significant impact on your weld quality and your bottom line. Similar to selecting your power source or wire feeder, the goal is to find the most cost-effective MIG gun that is capable of providing you with the performance that you need for your welding application. Regularly executing preventive maintenance can then help you protect that investment. Here are some tips to help you select the right MIG gun for your application and maintain it properly. Choose the Right MIG Gun for Your Application It is a common misconception that a welding procedure requiring 400 amps, for example, also requires a 400-amp MIG gun capable of operating at those amperage levels 100 percent of the time (i.e., 100 percent duty cycle). The fact is you spend time moving parts, grinding, tacking and completing other such tasks as opposed to welding nonstop. That means that you can often purchase a smaller amperage MIG gun — a 300-amp model would suffice — for applications in which duty cycle is less than 100 percent (e.g., 60 percent) for less money and still have it operate at the appropriate capacity. A smaller, lower-amperage MIG gun also weighs less and can help reduce wrist fatigue that could lead to downtime. It offers the added benefit of being easier to maneuver, which can help improve weld quality, too, and lessen rework. When possible, using shorter power cables on your MIG gun can further minimize costs and downtime. As a general rule, shorter power cables are less expensive and, like a smaller MIG gun, offer better maneuverability. Shorter power cables also help minimize wire-feeding problems associated with kinking and coiling, so you can spend more time welding and less time resolving these issues. Other factors you should consider when selecting your MIG gun: Consider using the smallest handle that can still meet your amperage needs. As with a smaller gun, smaller handles are easier to maneuver and can lessen fatigue. Some manufacturers also offer ventilated handles that help reduce heat and make it more comfortable to use for longer periods of time. Maintaining Your MIG Gun Check the feeder connection: Regularly check the wire feeder connection (where the power pin plugs into the feeder) to be certain it is tightened properly and that there is no dirt or debris on it. Loose or dirty wire feeder connections can cause heat to build up, leading to voltage drops that adversely affect the welding arc and may cause premature gun failure. Tighten the connection according to the manufacturer’s specifications or replace the direct plug if necessary to obtain a secure fit. Also inspect the O-rings for cracks that could lead to gas leaks, and replace them as necessary. Gas leaks often cause spatter and porosity, which increases downtime for cleanup and rework. Properly care for your MIG gun liner: It is not uncommon during the course of welding for the MIG gun liner to become clogged with debris, particularly from the welding wire. Over time, however, this accumulation of debris can lead to poor wire feeding, bird-nesting and burnbacks that require downtime to rectify. To maintain your liner, you can use compressed air to clear out potential blockages when you change wires. Also, tracking the length of time it takes for your liner to wear can help you better know when to replace the next one before you encounter problems. Always follow the manufacturer’s recommendation for trimming and installing the liner to prevent kinking and wire-feeding problems. Inspect the handle and trigger: Typically these components require little maintenance beyond visual inspection. Regularly look for cracks on the handle or Check the MIG gun neck: Loose connections at either end of the neck can cause electrical resistance that leads to poor weld quality and/or consumable failures. Check regularly to ensure tight neck connections. Also, visually inspect the insulators on your MIG gun neck and replace if damaged. These insulators prevent electrically live components from exposure, ensuring your safety and the longevity of your equipment. Visually inspect the power cable: Power cable maintenance is a very important part of eliminating uncessary equipment costs. Regularly inspect the power cable for damage, including cuts or kinks, and replace it as necessary. Cuts in the cable can expose copper wire and lead to a potential shock hazard, while kinking obstructs gas flow and wire feeding. The latter can lead to weld defects and arc instability that require downtime to remedy. Be mindful of your consumables: Frequently inspect your MIG gun nozzle and contact tip for signs of spatter build-up, which can obstruct shielding gas flow and cause weld defects that will need to be reworked. Spatter build-up can also cause your consumables to fail prematurely. Replace both consumables if spatter build-up appears or clean according to the manufacturer’s recommendation. Also, be certain that these components (and the gas diffuser) are securely connected. Loose connections can increase electrical resistance, which in turn leads to poor welding performance and can shorten the life of your consumables, adding to your overall costs. Remember, just like the power source and wire feeder, your MIG gun can impact your weld quality, productivity and costs. Taking the time to select the proper MIG gun and maintain it regularly, however, can help this equipment last longer and ensure that you spend more time welding instead of resolving problems.

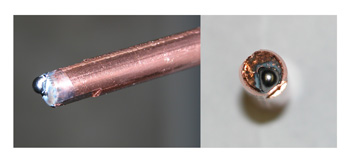

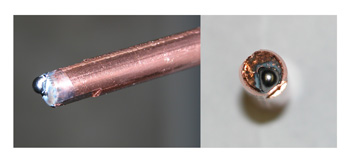

From the power source to the welding wire, each of the components in an arc welding operation can have a significant impact on productivity. The welding gun and consumables — nozzles, contact tips and diffusers — in particular, are often an overlooked aspect of the whole process, but these components directly affect quality, welder comfort, rework, downtime and more. There are three key ways in which guns and consumables used in flux cored arc welding (FCAW) and gas metal arc welding (GMAW) can lead to improved productivity: The contact tip is the last point of contact between the welding equipment and the welding wire, as well as the consumable responsible for generating the electrical connection to create the arc. As the wire passes through the contact tip, it can often erode the inside of the tip bore, leading to interruptions in the electrical current and causing poor arc stability. During the normal course of welding, especially at higher amperages, the contact tip can also become loose and cause a burnback (or the formation of a weld inside the contact tip). Burnbacks are often a significant source of downtime in a welding operation — and a big hindrance to productivity. Having a contact tip that stays securely placed during the course of welding is key to combating burnbacks. Brooklyn Iron Works (Spokane, Wash.) found just such a solution when they converted to Centerfire™ contact tips last year. Like other structural fabrication companies, Brooklyn Iron Works faces stringent deadlines for its projects, so the ability to minimize downtime for burnbacks and any other equipment management is imperative. Their welding personnel run their weld beads at high amperages (300 to 400 amps) using typically .052- or 1/16-inch FCAW wire diameters, which often proved too harsh on their previous contact tips. They would loosen after routine welding, causing the wires to arc back and create the burnback. “Before we converted to the new contact tips, we had a substantial amount of downtime for contact tip changeover,” explains QA Manager, Phil Zammit. “And that’s money. It’s lost arc time for tip maintenance. Now we are using a third fewer tips and don’t have to worry about the downtime like before.” The company’s new contact tips don’t loosen because they “drop in” the diffuser and are locked in place by tightening the nozzle. They also feature a non-threaded tip design with a tapered base and large diameter seat. The other benefit of the design is that it helps generate consistent electrical conductivity and heat transfer, both of which help the consumables last longer and perform more reliably. Brooklyn Iron Works’ welding operators frequently encounter weld joints up to 2-in. deep. In the past, they often had to extend their electrode stickout as far as 2 inches to access the joints, a practice that risked generating porosity since it could compromise the necessary shielding gas coverage. Brooklyn Iron Works has found their solution to porosity is to have the right size and shape of nozzle for the application. Switching to Centerfire consumables now allows them to reduce electrode stick-out and gain better gas coverage at the same time. “These consumables direct the gas exactly where we need it,” Zammit explains. “It keeps our gas shielding coverage right at the weld, even when the doors are open or we have a breeze. We’ve never had a huge problem with porosity, but now we have even less of one.” The nozzles feature a tapered shape that stays fixed flush with the contact tip. They also include a built-in spatter shield that acts as an additional gas diffuser and ensures a more consistent directional gas flow, even on deep joints or if there is a slight breeze present. The typical welding operator spends time during a shift allocated to joint preparation, part fit-up and movement, along with other activities that contribute to the throughput of the welding operation. But during the actual process of welding, it is critical that he or she remain comfortable. Good welding operator comfort lessens the chances of injuries associated with repetitive movement and reduces overall operator fatigue. And a more content employee also brings forth the potential for greater productivity. Welding operators at Brooklyn Iron Works have addressed the issue of comfort through the various necks available on their Bernard 400-amp Q-Guns. The Q-Guns are available with fixed, rotatable and flexible necks in various lengths and bend angles. These neck options help the welding operators better accommodate the varying welding angles they encounter on projects. They can reach the weld joints better and minimize downtime to address issues like wrist fatigue. The flexible necks are especially helpful on difficult joints, as they can be adjusted to weld around corners or to fit into complex shaped steel components. Welding operator Ricky Curtis explains, “I can bend the neck in any direction I need. Even around the corners. I like that the gun does the work for me, instead of my wrist.” According to the company’s maintenance supervisor, John Dahl, there have been additional benefits to the design of the gun as well. “It takes only about five minutes to change a neck on these guns, compared to nearly an hour with our previous guns,” he explains. This ease of maintenance is another way in which having the equipment has helped Brooklyn Iron Works reduce downtime and get back to welding faster. Remember, in the long run, companies can benefit from looking at how every aspect of their welding operation impacts downtime. Time spent for changing out contact tips or maneuvering unnecessarily into difficult joints can ultimately hinder productivity, as can having welding guns that are time-consuming to maintain. Addressing the problem of productivity may be as simple as looking at a new consumable option or finding ways to make the welding operators more comfortable.

Gas metal arc welding (GMAW) involves more than just arc-on time. Welding operators also need to be mindful of other activities that contribute to the overall productivity and quality in the welding operation, including proper joint preparation, following correct weld parameters and ensuring good part fit-up. Selecting the proper GMAW gun, consumables and shielding gas is also critical to achieving good results. Unfortunately, it is not uncommon for there to be confusion as to how these components affect the welding operation. The reality is, however, that they can have a significant impact on downtime and costs, not to mention operator comfort. The goal is to make sure that impact is positive. Following are answers to some common questions about GMAW guns, consumables and shielding gas to help you select the best ones for your welding operation and manage them in a way that provides optimal results. When it comes to GMAW guns, bigger isn’t always better. In fact, selecting a larger amperage gun than needed for your application may cost you money in the long run and lead to discomfort, which results in unnecessary downtime. Duty cycle is defined as the amount of arc-on time within a 10-minute period, so a 20 percent duty cycle would constitute two minutes of arc-on time in a 10-minute time frame. Because most welding operators don’t weld 100 percent of the time, it is often possible to use a lower amperage gun for a welding procedure that calls for a higher amperage one. For example, in many cases you could use a 300-amp gun model in place of a 400-amp gun model, since actual arc-on time often does not exceed the amperage to duty cycle ratio of a 300-amp gun. The benefit is that the lower amperage gun generally costs less money — and it also weighs less, which can help reduce wrist fatigue, commonly associated with downtime. The lower amperage GMAW gun will still be capable of operating at the appropriate capacity, while also offering the benefit of being easier to maneuver – a factor than may help you improve weld quality and lessen rework, too. There are several factors to consider when choosing your GMAW gun. After determining your amperage needs, you should also look for features like a rigid, strong strain relief. Strength in this area between the power pin and cable can help minimize kinking, which often leads to an unstable arc and/or poor wire feeding. Next, consider selecting a smaller handle gun (but one that can still meet your amperage needs), as it may help reduce wrist fatigue and be easier to maneuver into complex joints. You may also want to consider looking for a specific style of neck for your application. Many GMAW gun manufacturers offer fixed, rotating and flexible necks in various lengths and angles, allowing you to reach joints more easily. Regardless of the style of neck you choose, you should find one with good armor to protect it against damage that could lead to electrical shorts or premature failure. Finally, select a GMAW gun with a comfortable and easy-to-service trigger. Typically, you will be able to find a variety of trigger options, including standard style, locking or dual schedule. Regardless of the specific style, look for sturdy triggers that will withstand work site abuse and that can be easily replaced should one of the mechanics fail. Shielding gas prevents exposure of the molten weld pool to oxygen, nitrogen and hydrogen contained in the air atmosphere, in order to protect the weld from contamination and/or defects. The type you use can impact everything from the penetration profile to arc stability and the mechanical properties of the finished weld. If you need deep weld penetration, particularly on thick materials, carbon dioxide (CO2) is a good choice and it is also the least expensive. This gas, however, does tend to create spatter and is limited to use in short circuit welding. Adding 75 to 95 percent argon to the CO2 can provide better arc stability and puddle control, both of which reduce spatter compared to straight CO2. This mixture will also allow you to use a spray transfer process, allowing you to weld faster in many cases. Argon also produces a narrower penetration profile that is useful for fillet and butt welds. If you’re welding a non-ferrous metal — aluminum, magnesium or titanium — you’ll need to use 100 percent argon. In some cases, oxygen or helium is used in the GMAW process, but it is not as common. Consumable service life can vary dramatically from application to application. There are a few steps you can take to make them last longer, however. First, use the correct contact tip for the size wire who have and be certain it fits securely with the gas diffuser. A solid connection between these components helps ensure good conductivity and minimize overheating, making them last longer. Also, inspect your nozzle on a regular basis for spatter and clean as necessary. Use a pair of welding pliers or a special nozzle-cleaning tool for the job, as directed by the consumable manufacturer. Be sure, too, that you have the appropriate type of consumables for your application. Applications above 300 amps, for instance, can often benefit from heavy-duty consumables, which have greater mass and can dissipate heat more readily. The result, in many cases, is longer service life. Finally, set the drive roll tension on your wire feeder so that the wire feeds properly. Doing so prevents deformities in the wire (in the case of too high of tension) that may cause the wire to wear out the contact tip prematurely. Cutting a GMAW liner too long can cause it to become misaligned with the gas diffuser. Conversely, cutting a liner too short may lead to debris build-up between the liner and gas diffuser. Both instances can lead to poor wire feeding, weld quality issues and premature contact tip failure. To prevent this problem, always follow the manufacturer’s instructions for installation, making certain that the liner is free of any burrs or short edges after you trim it. A smooth cut helps ensure smooth and consistent feeding of the welding wire. Some manufacturers offer a liner gauge to help you determine the proper length for your particular liner, while others print markings on the outside of the weld cable to show when the liner is twisted, allowing for more accurate trimming. If your gun does not have these markings, make sure the cable is fully extended when inserting the new liner. Remember to wear gloves when handling the liner and avoid dragging it on the ground. These precautions help prevent debris from being introduced into the GMAW gun and causing weld contamination and/or poor consumable performance. Burnback is one of the most common causes of downtime in a GMAW application and is a significant cause of premature contact tip failure. Proper equipment setup is one of the key defenses to protect your consumables. First, be sure that you have established the appropriate contact tip recess and wire stick out for your application, and that you maintain a correct contact-tip-to-work distance. Check electrical connections regularly and replace worn work leads or cables, as faulty ones can also cause the problem. Make sure to maintain the proper drive roll tension and install your liner properly, too. Both precautions minimize erratic wire feeding that could lead to burnbacks. Storing and handling GMAW consumables properly not only helps them last longer, but also perform better. Never store your GMAW consumables loose in a bin, since it can cause scratches on them that attract spatter and may lead to premature failure. Instead, keep them in their original packaging until you are ready to use them. Doing so will also protect the components from contaminants such as dirt or oil. Finally, always wear clean gloves when handling or replacing contact tips, nozzles and diffusers. Again, it helps prevent dirt, oil or other contaminants from adhering to them and also potentially entering the weld puddle. Like any welding process, GMAW has many factors to consider in order to achieve the best results. Make sure that you don’t overlook the impact of your GMAW gun, consumables and shielding gas as part of those. Being mindful of the selection process, storage and handling, and installation, among other things, can be beneficial to both your productivity and your bottom line in the long run.

Avoid These 5 MIG Gun Myths to Optimize Performance

Avoid These 5 MIG Gun Myths to Optimize Performance

Myth #1 — MIG guns are all the same, so price should be the deciding factor when purchasing a new gun.

Myth #2 — Consumables aren’t very important to weld quality and performance.

Myth #3 — Preventative gun and consumables maintenance is a waste of valuable time that could be better spent in production.

Myth #4 — It’s always better to err on the safe side and overmatch the gun amperage to the application.

Myth #5 — The MIG gun liner does not have a significant impact on welding performance.

Finding a MIG Gun That Fits

Finding a MIG Gun That Fits: Stay Cool and Comfortable While Welding

Selecting the Right Amperage

Getting a Handle On the Selection

Staying Cool

Putting It All Together

Maintaining Your MIG Gun… and Your Welding Costs

Maintaining Your MIG Gun… and Your Welding Costs

We all have the tendency to fall victim to the “bigger is better” philosophy. When it comes to purchasing a MIG gun, however, that thinking may cost you more money than is necessary for this equipment. It can also lead to costly downtime.

Regularly inspecting your MIG gun can be an important part of reducing costs and gaining good welding performance. Fortunately, preventive maintenance (PM) for a MIG gun doesn’t have to be time consuming or difficult. Consider these key factors.

missing screws. Check that your MIG gun trigger is not sticking or otherwise malfunctioning. Replace these components as necessary.

Three Ways Welding Guns and Consumables Can Improve Productivity

Three Ways Welding Guns and Consumables Can Improve Productivity

Contact Tips

Better Shielding

In addition to inadequate shielding gas, porosity can also occur if a welding operator uses too small of a nozzle for the application, extends the welding wire too far beyond the end of the nozzle or tries to weld with a nozzle full of spatter. Air from outside or from fans can create the problem, too, by blowing away much needed shielding gas.The Benefits of Comfort

GMAW Guns, Consumables and More – Common Questions Answered

GMAW Guns, Consumables and More: Common Questions Answered

How do I determine what amperage GMAW gun I need

Besides amperage, what else should I consider when selecting a GMAW gun?

What type of shielding gas is best for my application?

How can I make my GMAW consumables last longer?

What is the proper way to trim and install my GMAW gun liner?

How can I protect my contact tips from burnback?

What’s the best way to store and handle my GMAW consumables?